Static balance debugger for vertical gyroscope components

A gyroscope and static balance technology, which is applied in the field of static balance debuggers, can solve problems such as unqualified static balance debugging of vertical gyroscope components, and achieve the effects of simple structure, improved work efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

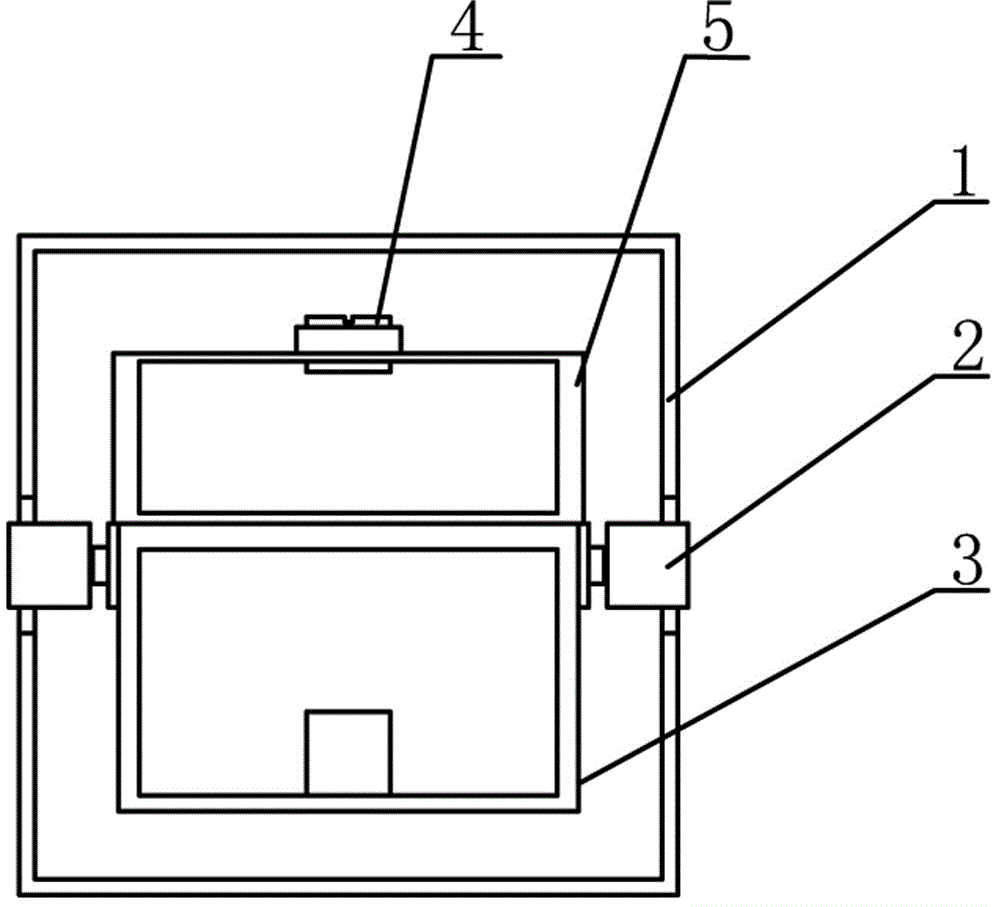

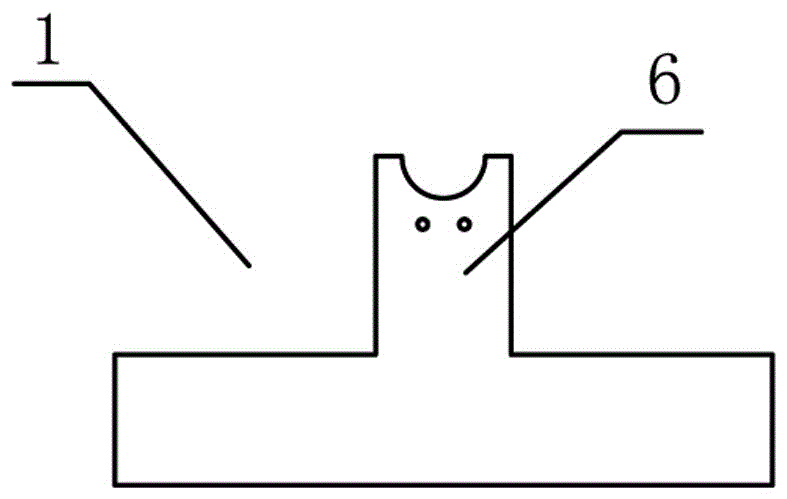

[0026] Such as Figure 1-12 As shown in , the vertical gyro component static balance debugger includes a base 1, a bearing frame 2, an inner seat 3, an adjustment screw 4, an inner frame 5, and the base 1 is a hollow rectangle with an open top surrounded by a rectangular side plate and a rectangular bottom plate The two sides of the base 1 are provided with support plates 6 for fixing the bearing frame 2. The inner seat 3 is a hollow T-shaped column with open sides formed by a circular top plate 10, an inner seat side plate 11 and a bottom plate 12. The top of the inner seat side plate A protruding shaft 9 is provided, and a T-shaped hole cylinder 8 for installing a vertical gyroscope assembly is arranged on the bottom plate 12. The inner frame 5 is an inverted hollow with two sides open formed by a circular bottom plate 13, an inner frame side plate 14 and a top plate 15. T-shaped column, the top plate 15 is provided with a T-shaped internally threaded hole cylinder 16, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com