Testing system for evolution process of deep mining stress field

An evolution process, deep mining technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the complex temporal and spatial relationship and dynamic characteristics of mining stress field, do not understand the law of temporal and spatial evolution, coal and gas outburst, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

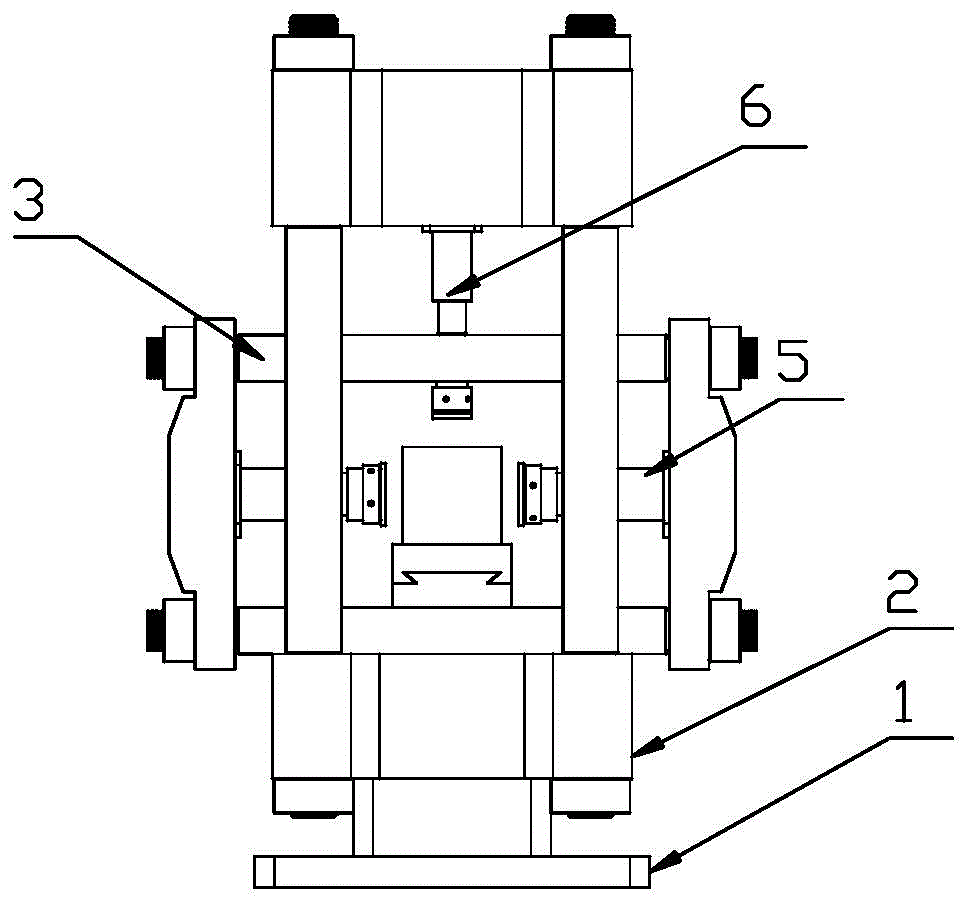

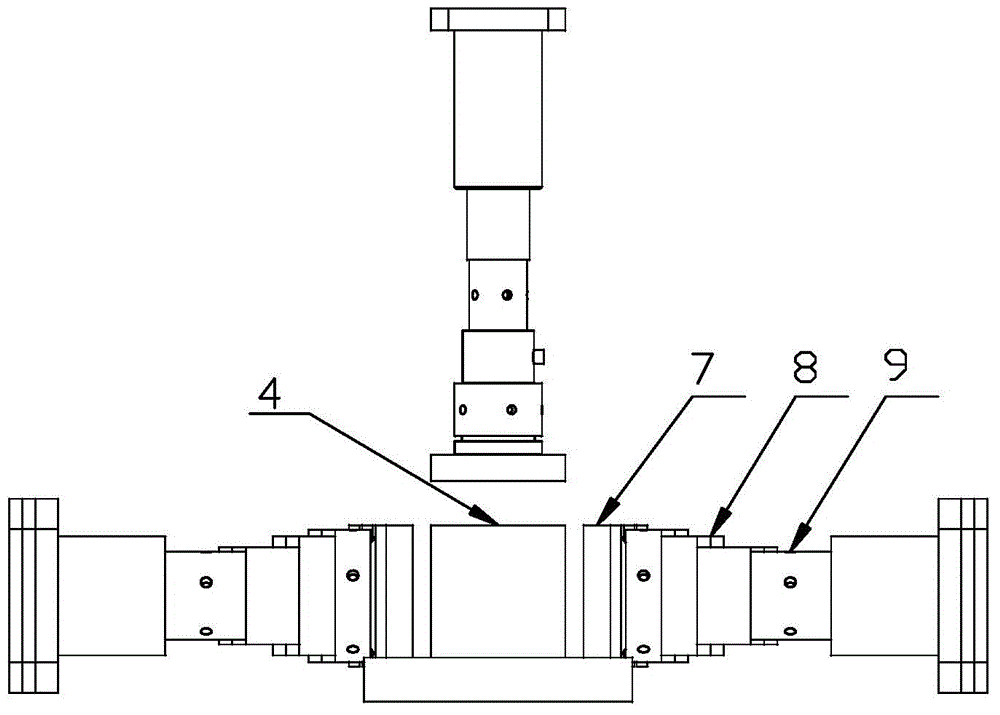

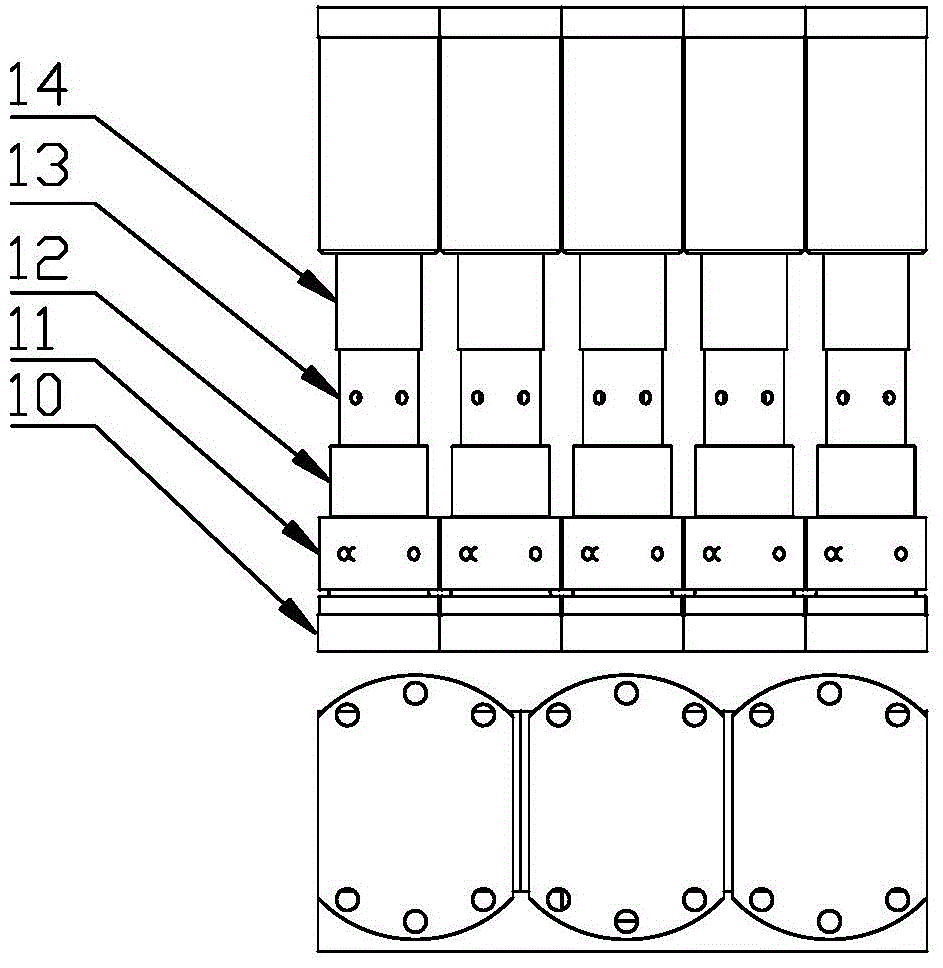

[0019] to combine figure 1 As shown, the deep mining mining stress field evolution process test system of the present invention includes a test loading assembly, a servo assembly, a control assembly and an acoustic wave monitoring assembly. The servo assembly, the control assembly and the acoustic wave monitoring assembly are used synchronously with the test loading assembly. The acoustic wave monitoring assembly In order to obtain a clearer evolution process of crack expansion, the servo components, control components and acoustic wave monitoring components are the same as those of the prior art, and only a brief description is given here;

[0020] The servo assembly is used for multi-level controllable constant oil flow control, which includes a dynamic stress servo unit, a servo motor and an EDC controller; the dynamic stress servo unit consists of a permanent magnet torque motor, a nozzle, a baffle, a spool, Composed of a valve sleeve and a control chamber, the EDC control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com