camera module

一种相机模组、相背的技术,应用在照相机、照相机的机身、电视等方向,能够解决匹配等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

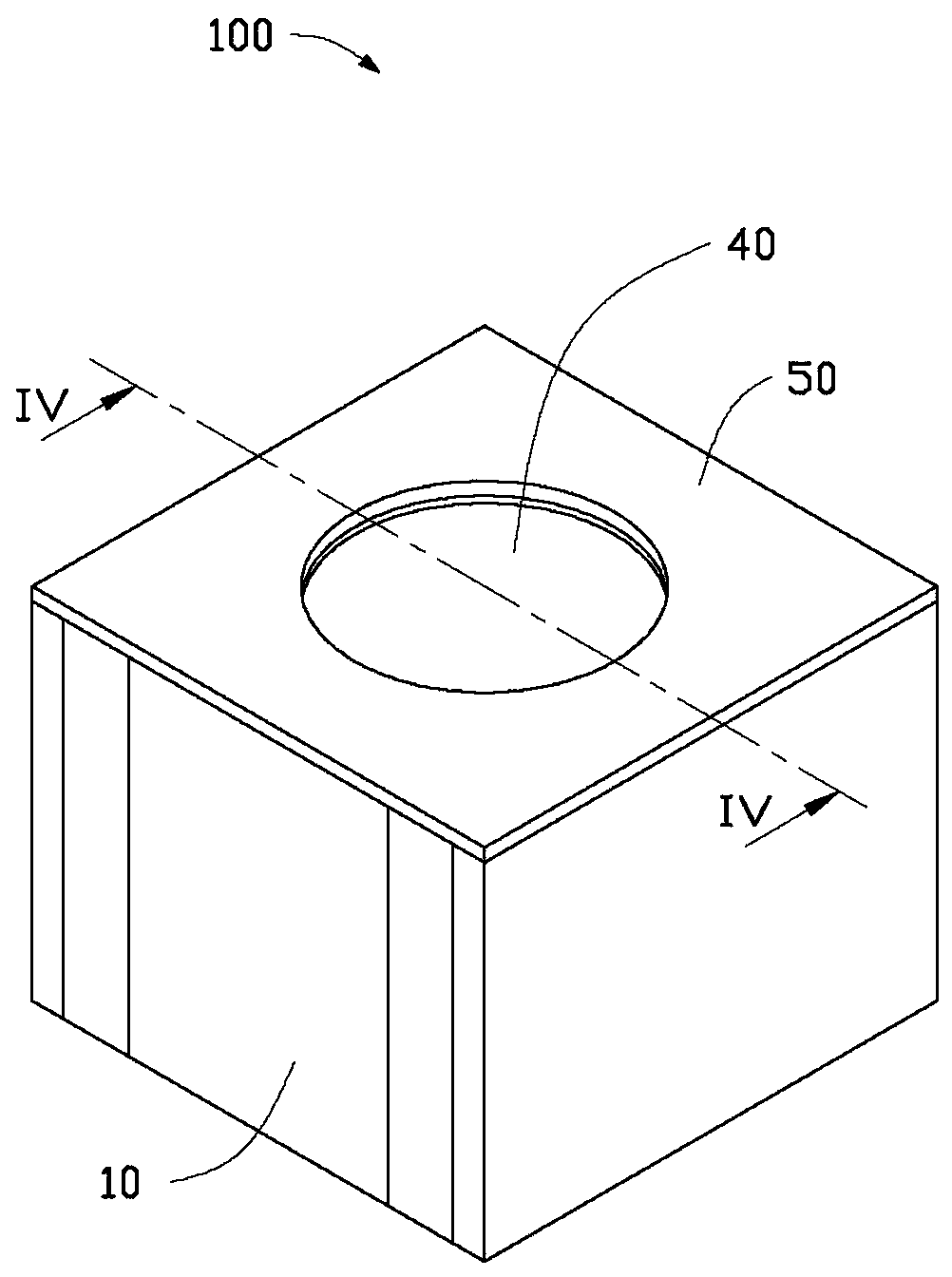

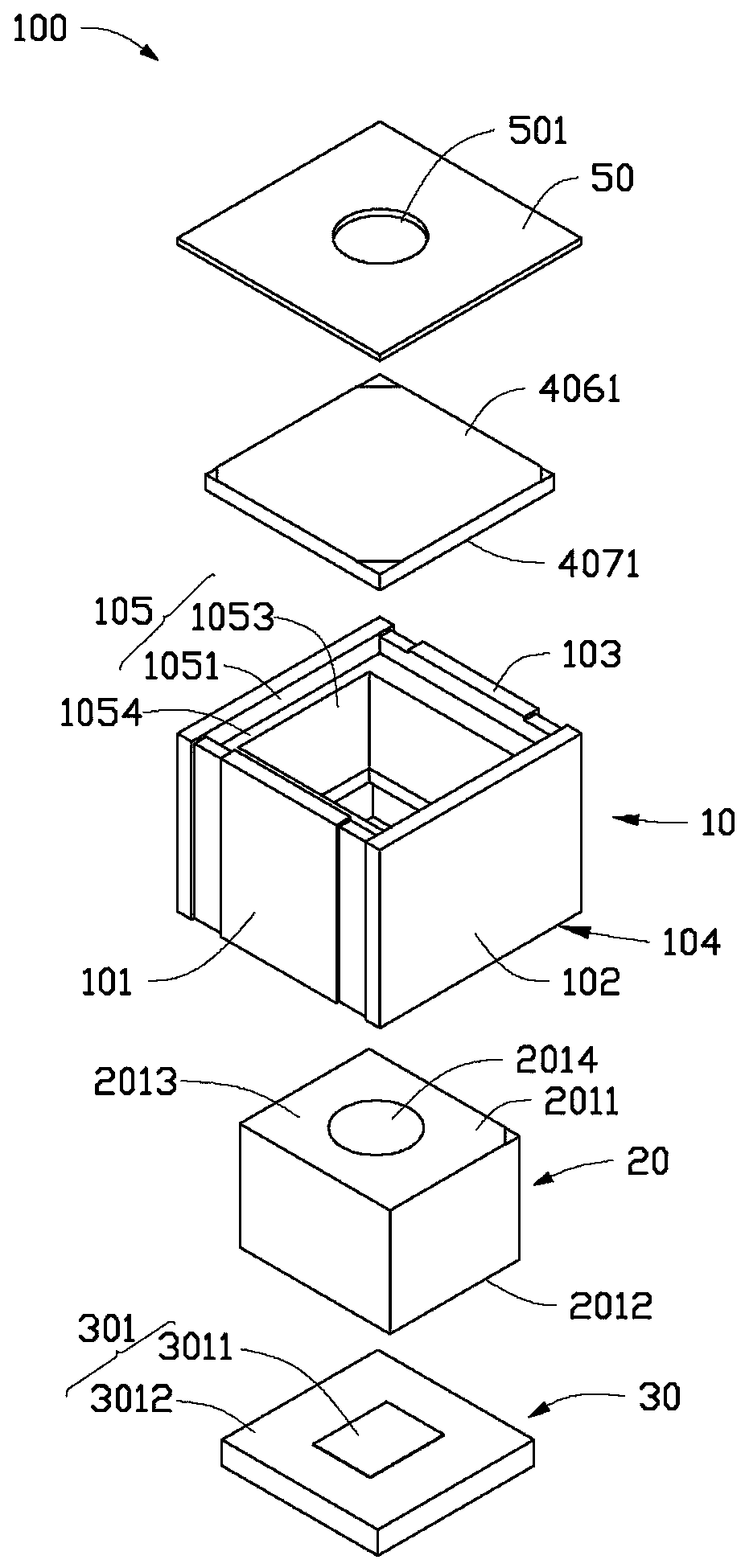

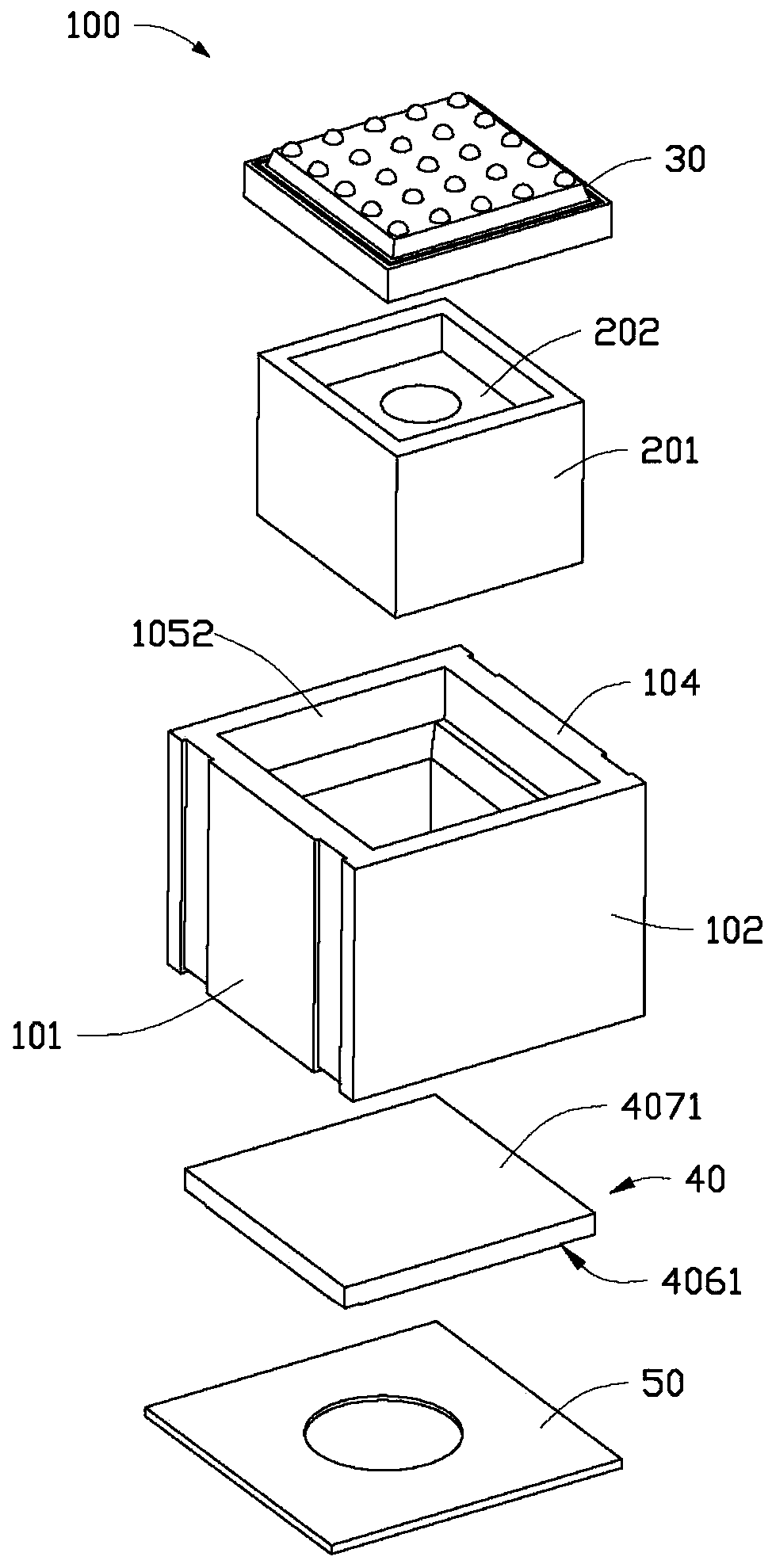

[0014] like Figure 1 to Figure 3 As shown, a camera module 100 provided by an embodiment of the present invention includes a frame 10 , a wafer-level lens 20 , an image sensor 30 , a liquid crystal lens 40 and a shading film 50 .

[0015] The frame 10 is made of plastic molding. In this embodiment, the frame 10 can be made of liquid crystal polymer (liquid crystal polymer, LCP) and is black. In other embodiments, the frame 10 is also Other colors are available. The frame 10 is a hollow cuboid and includes a pair of first side walls 101, a pair of second side walls 102 vertically connected to the first side walls 101, a first end surface 103 and a The end surface 103 is opposite to the second end surface 104 . The first end surface 103 and the second end surface 104 are two opposite end surfaces of the pair of first side walls 101 and the pair of second side walls 102 . Both the first end surface 103 and the second end surface 104 are substantially square. The frame 10 def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com