Foldable telescopic high-efficiency motor dust shield

A telescopic, dust-proof cover technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., to facilitate handling and storage, and reduce movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

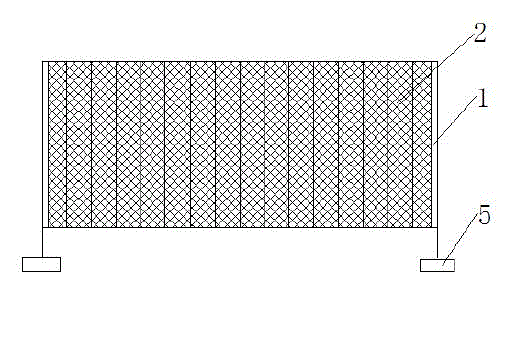

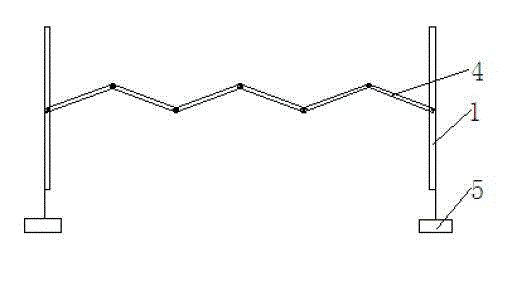

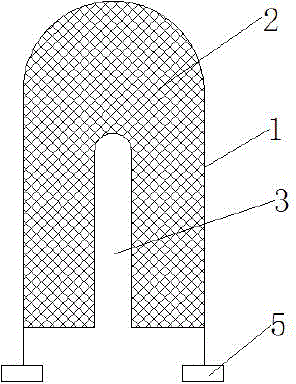

[0011] figure 1 , figure 2 and image 3 A specific embodiment of the present invention is shown: the motor dust cover includes a support frame 1 and a dust-proof net 2, the support frame 1 is two independent arch-shaped support frames, and a dust-proof net 2 is connected between the two, The two support frames 1 are also provided with a dust-proof net 2, and the dust-proof net 2 on one of the support frames 1 is provided with an inverted "U"-shaped mouth 3, and the dust-proof net 2 connected between the two support frames 1 is Folded structure, a foldable connection mechanism is provided between the two support frames 1 in the horizontal direction. The connection mechanism is composed of a plurality of support rods 4 hinged from head to tail in turn, and the unconnected end of the first support rod 4 is connected to one of them. The support frame 1 is hingedly connected, and the unconnected end of the last support rod 4 is hingedly connected with the other support frame 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com