Pored inner-tooth layered nozzle with 15-degree taper angle

A technology with internal teeth and holes, which is applied in the field of 15° cone-shaped hole-shaped layered nozzles with internal teeth to achieve the effect of strong blowing distance and strong blowing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

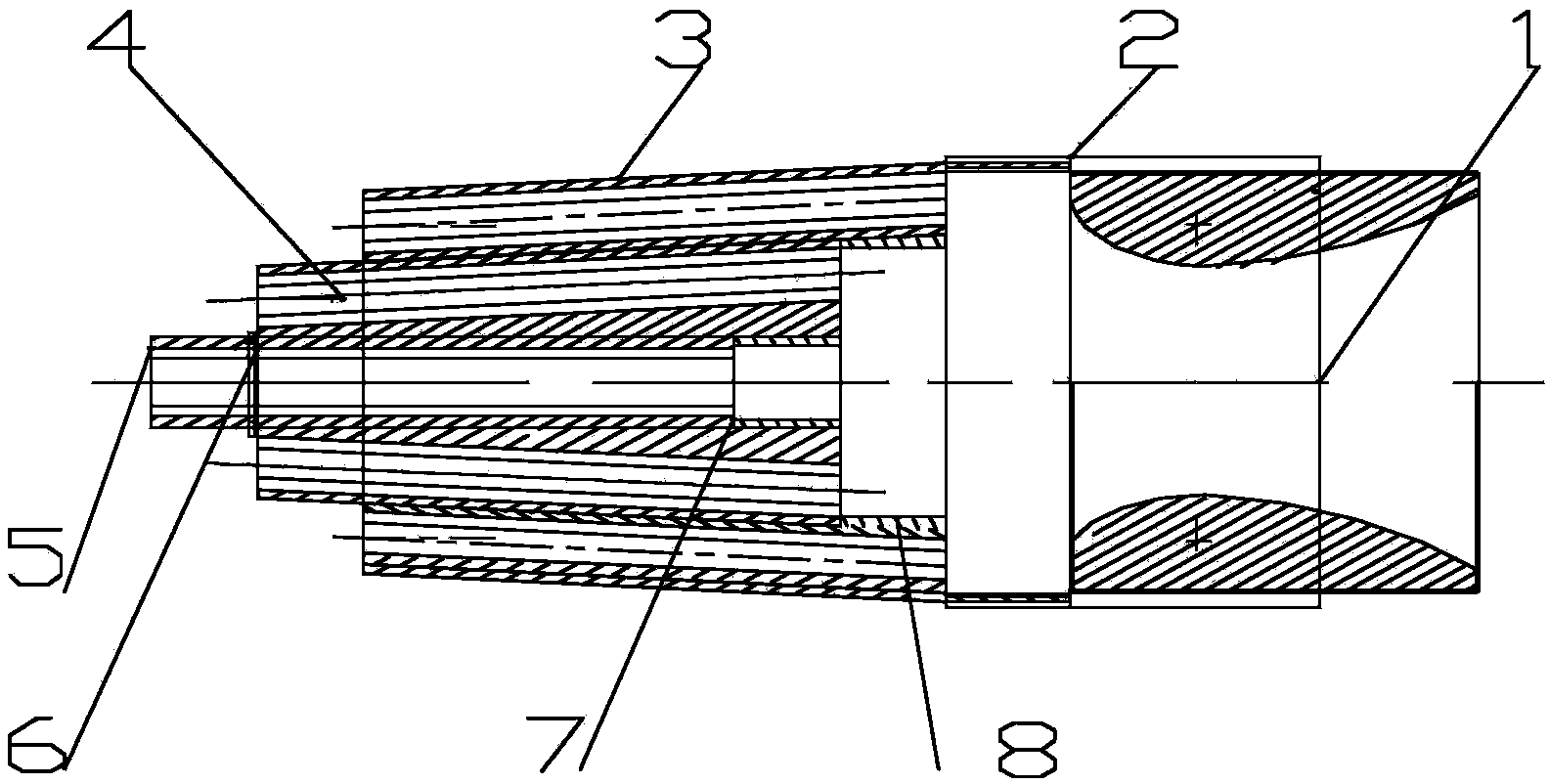

[0018] [0011] Embodiment 2. The assembly and connection sequence of each part of the 15° cone-shaped hole-shaped internal tooth layered shower head is: the tapered layered body III (5) is loaded into the front end, and then loaded with the tapered layered body II (4 ), the front end adopts the positioning elastic retaining ring (6) to locate the tapered layered body III (5) and the tapered layered body II (4), and the rear end uses the expansion sleeve (7) for transition fit connection. Then put the two into the tapered layered body I (3), and use the rear end to adopt the expansion sleeve (87) for transition fit connection, and then screw the tapered layered body I (3) into the main body (2), Finally screw the main air chamber (1) into the other end of the main body (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com