Enhanced synchronous belt

A synchronous belt, enhanced technology, applied in the field of transmission, can solve the problems of weak adhesion, weak shear resistance, tearing, etc., to reduce labor costs and material costs, increase the shear strength of the tooth layer, and increase the belt body strength and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

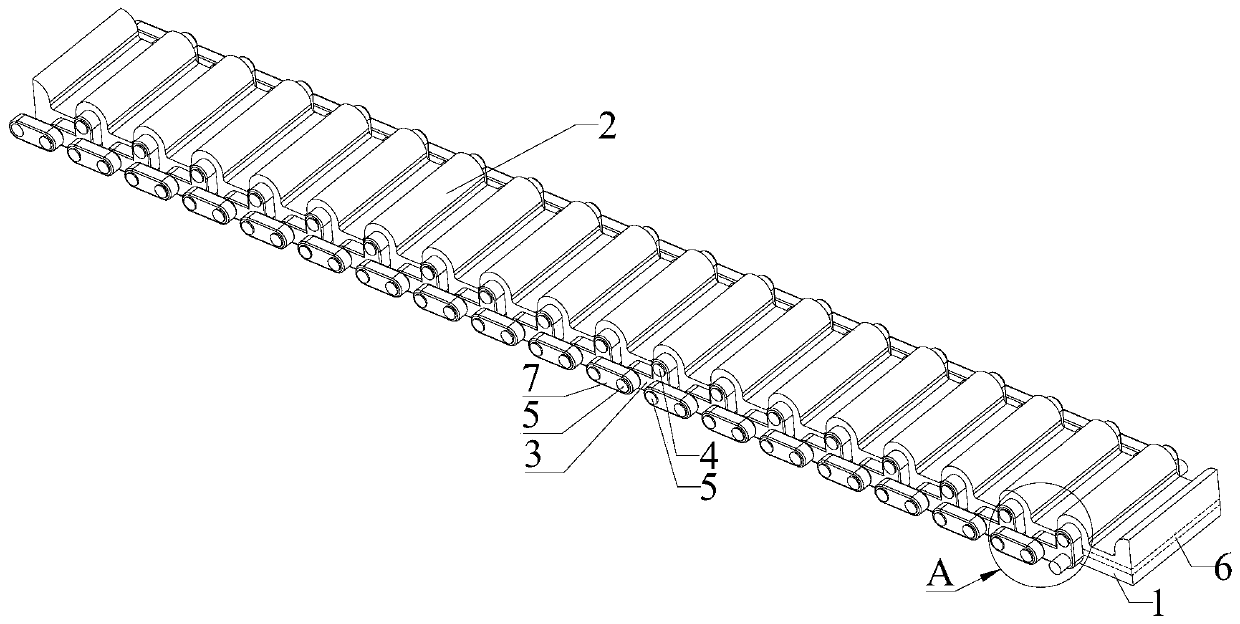

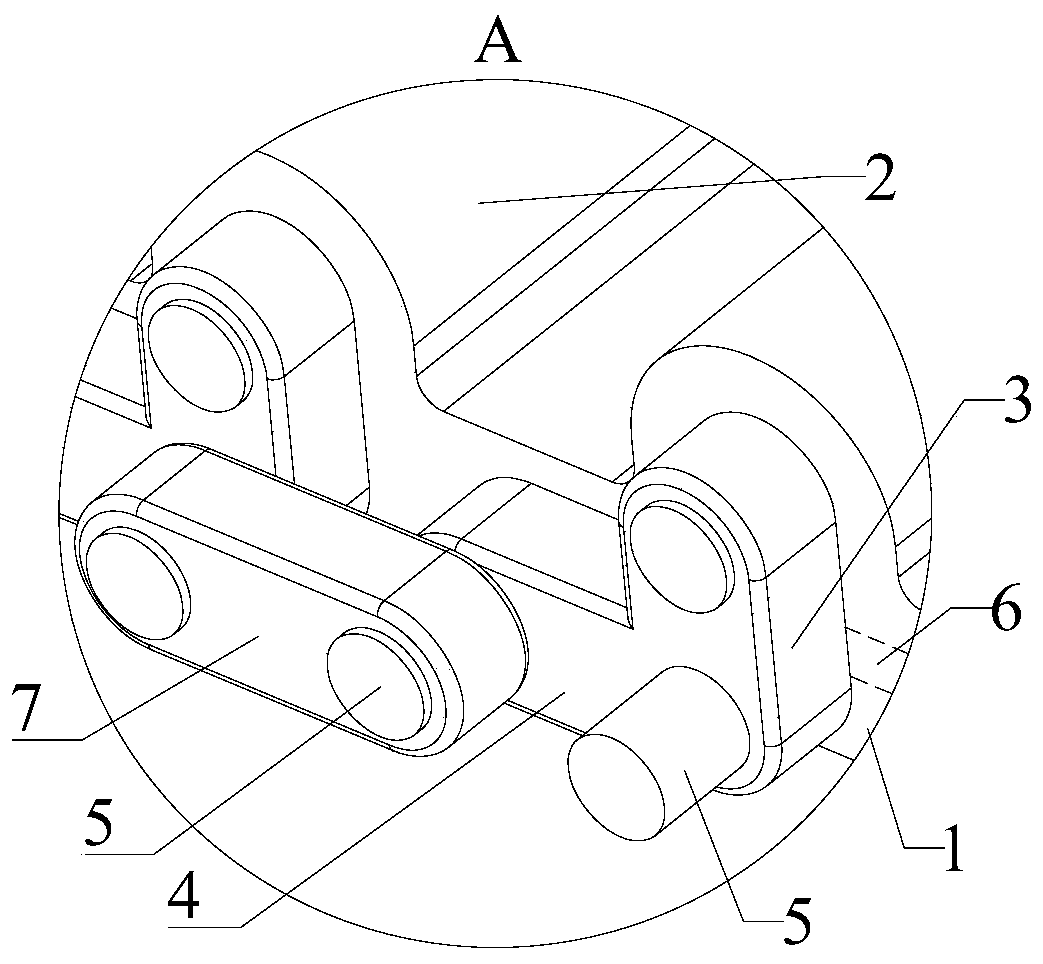

[0036] Please refer to figure 1 with figure 2 , Embodiment 1 of the present invention is: an enhanced synchronous belt, which can be used in the fields of mechanical transmission, robot transmission, electromechanical product transmission, sports product transmission and other transmission fields.

[0037] The reinforced synchronous belt includes a belt body layer 1, the inner side of the belt body layer 1 is provided with a tooth layer 2, and also includes a reinforcement unit, and the reinforcement unit includes a first connecting piece 3, which is arranged in the tooth layer 2 The first shaft 4 and the second shaft 5 arranged on the body layer 1, the first shaft 4 and the second shaft 5 are respectively connected in rotation with the first connecting member 3.

[0038] The body layer 1 is embedded with a core layer 6 , preferably, the second axis 5 is located on a side of the core layer 6 away from the tooth layer 2 .

[0039] In order to balance the force of the timing ...

Embodiment 2

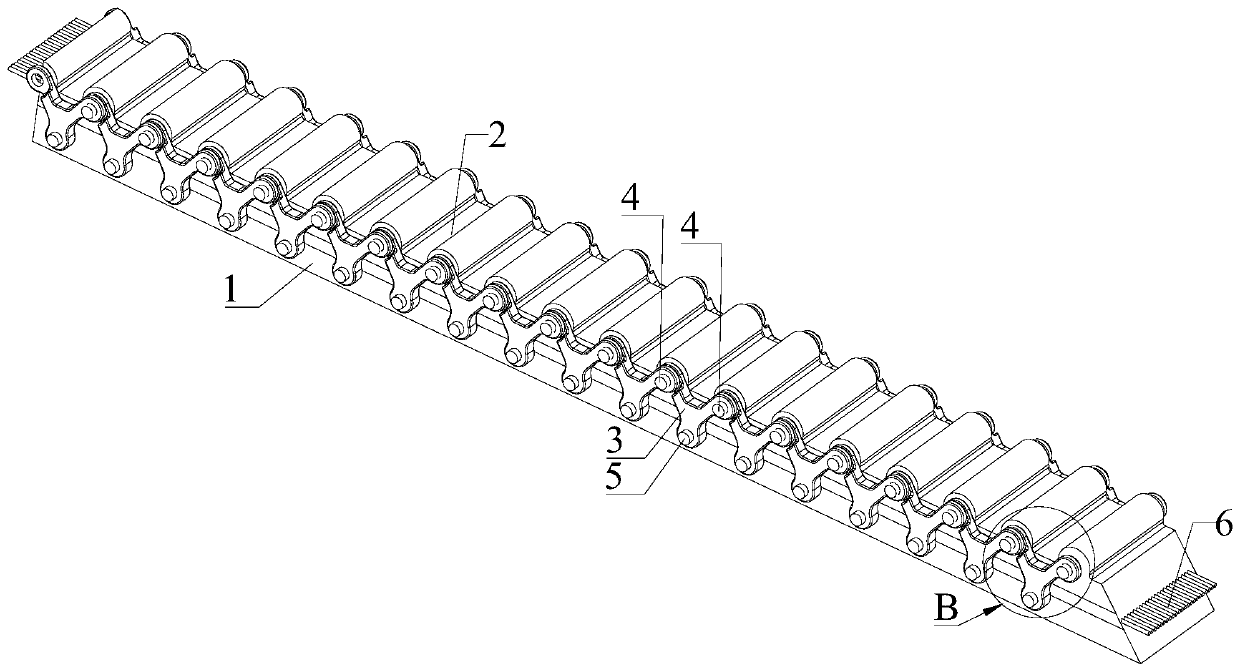

[0045] Please refer to image 3 with Figure 4 , Embodiment 2 of the present invention is a modification proposed on the basis of Embodiment 1. The difference from Embodiment 1 is:

[0046] In the reinforcing unit of the reinforced synchronous belt in this embodiment, the number of the first shaft 4 and the second shaft 5 is one respectively, the first connecting member 3 is V-shaped or Y-shaped, and the second shaft 4 is V-shaped or Y-shaped. A connecting piece 3 is also rotatably connected to the first shaft 4 in another adjacent reinforcement unit. It is easy to understand that the V-shaped or Y-shaped first connecting member 3 can be an integral structure, or a spliced structure formed by splicing a plurality of connecting rods.

[0047] Further, the distance between the first shaft 4 and the second shaft 5 in the reinforcement unit is equal to the distance between the second shaft 5 and the first shaft 4 in another adjacent reinforcement unit .

[0048] To sum up, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com