Preparation method of dual-layer holographic anti-counterfeiting film, product with dual-layer holographic anti-counterfeiting film, and recognition method

A holographic anti-counterfeiting and production method technology, which is applied in the field of holographic anti-counterfeiting printing, can solve the problems of weakening anti-counterfeiting functions of ordinary lasers, and achieve the effects of expanding the amount of anti-counterfeiting data information, accurate comparison, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

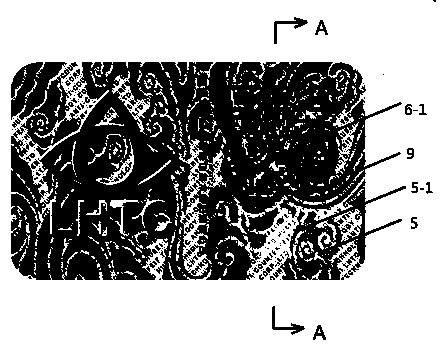

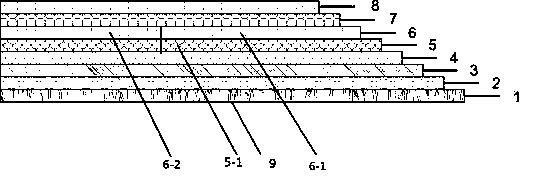

[0021] Embodiment 1: A kind of two-dimensional code holographic anti-counterfeiting method, such as figure 2 As shown, the specific steps are:

[0022] The first step: making a separation layer 2 on the PET base film 1;

[0023] Second step: coating the imaging layer 3 on the separation layer 2;

[0024] The third step: molding the holographic image to make the laser information layer 4;

[0025] Step 4: Partially spray and print a two-dimensional code 6-1 on the laser information layer 4, the code printing of the two-dimensional code 6-1 on the laser information layer 4 is precisely positioned and printed at a specific position; the laser The two-dimensional code 6-1 on the information layer 4 is a logically editable variable two-dimensional code 6-1, and each two-dimensional code 6-1 is unique, constituting the two-dimensional code layer 6; the two-dimensional code printed by spraying 6-1 is a logically edited two-dimensional code 6-1, which can represent multiple langua...

Embodiment 2

[0034] A kind of manufacture method and product thereof of double-layer holographic anti-counterfeiting film, such as figure 2 As shown, the specific steps are:

[0035] The first step: making a separation layer 2 on the PET base film 1;

[0036] Second step: coating the imaging layer 3 on the separation layer 2;

[0037] The third step: molding the holographic image to make a laser information layer;

[0038] Step 4: Partially spray and print a two-dimensional code on the laser information layer, the code printing of the two-dimensional code on the laser information layer is precisely positioned and printed at a specific position; the two-dimensional code on the laser information layer is Logical editing of variable QR codes, the QR codes implicitly contain a unique number corresponding to the digital code, and each QR code is unique, forming a QR code layer;

[0039] Step 5: Apply random holographic color film on the laser information layer to form a double-layer hologra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com