Table plate for train seat

A table board and seat technology, which is applied to railway car body parts, transportation and packaging, can solve the problems of inability to freely adjust the distance between the table board and the human body, and inconvenient turning operations, and achieve the effect of stable bearing and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

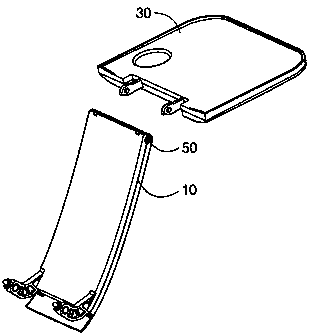

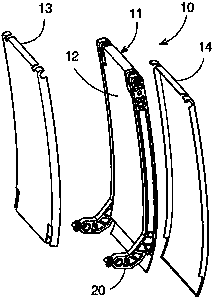

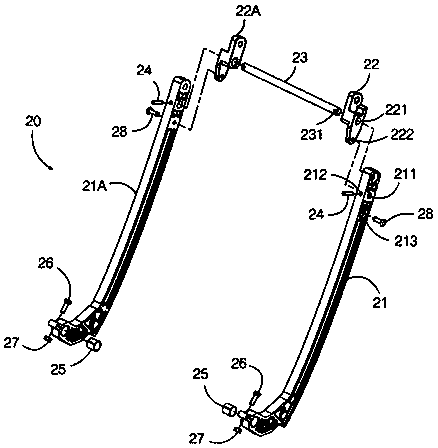

[0020] 10 Arm assembly structure, 30 Pallet assembly structure, 40 Pallet frame, 50 Shaft structure, 11 Arm body, 13 Front cover, 14 Rear cover, 31 Pallet body, 33 Upper cover, 34 Lower cover plate, 35 Desktop cooling plate, 36 Cup holder cooling plate, 20 Arm skeleton, 21 Supporting arm, 22 Positioning block, 23 Cross bar, 24 Pin shaft, 25 Damping bushing, 26 Screw, 27 Adjusting nut, 28 Blind rivets, 41 bearing bracket, 42 chute frame, 43 circular bar, 44 damping chute, 45 slide bar, 46 thrust pin, 51 shaft screw, 52 flange bushing, 53 liner, 219 step perforation , 351 sliding bar perforation, 224 threaded hole, 211 first arm hole, 212 second arm hole, 221 positioning block hole, 231 cross bar perforation, 213 first arm fixing hole, 222 second arm fixing hole, 215 Perforation of the first arm, 216 U-shaped groove, 217 Perforation of the second arm, 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com