Full-automatic symmetric box filler

A fully automatic technology called box packing machine, applied in the field of fully automatic symmetrical box packing machine, can solve the problems of unfavorable enterprise development and growth, low work efficiency, high labor cost, etc., to promote development and growth, low use cost and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

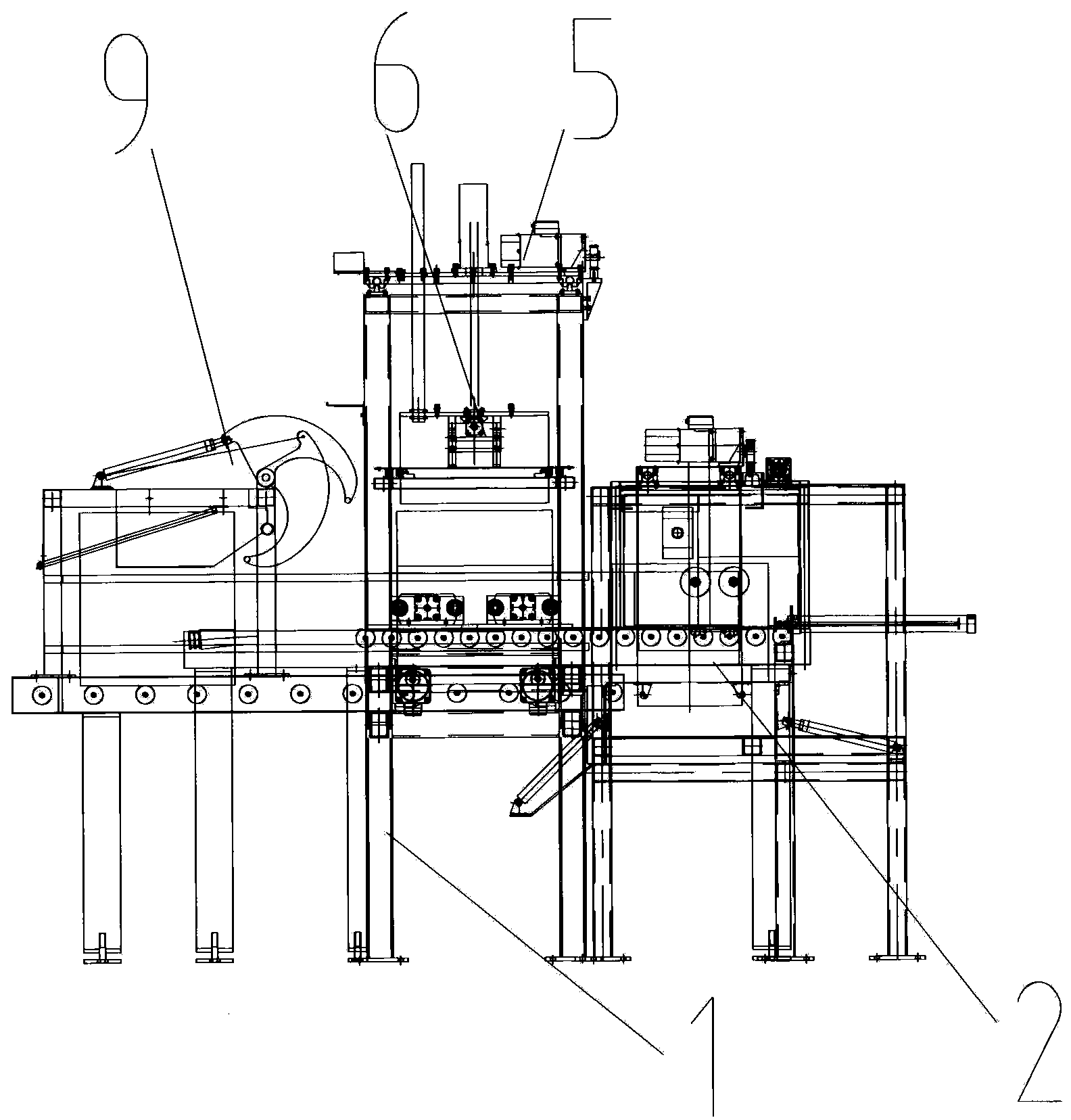

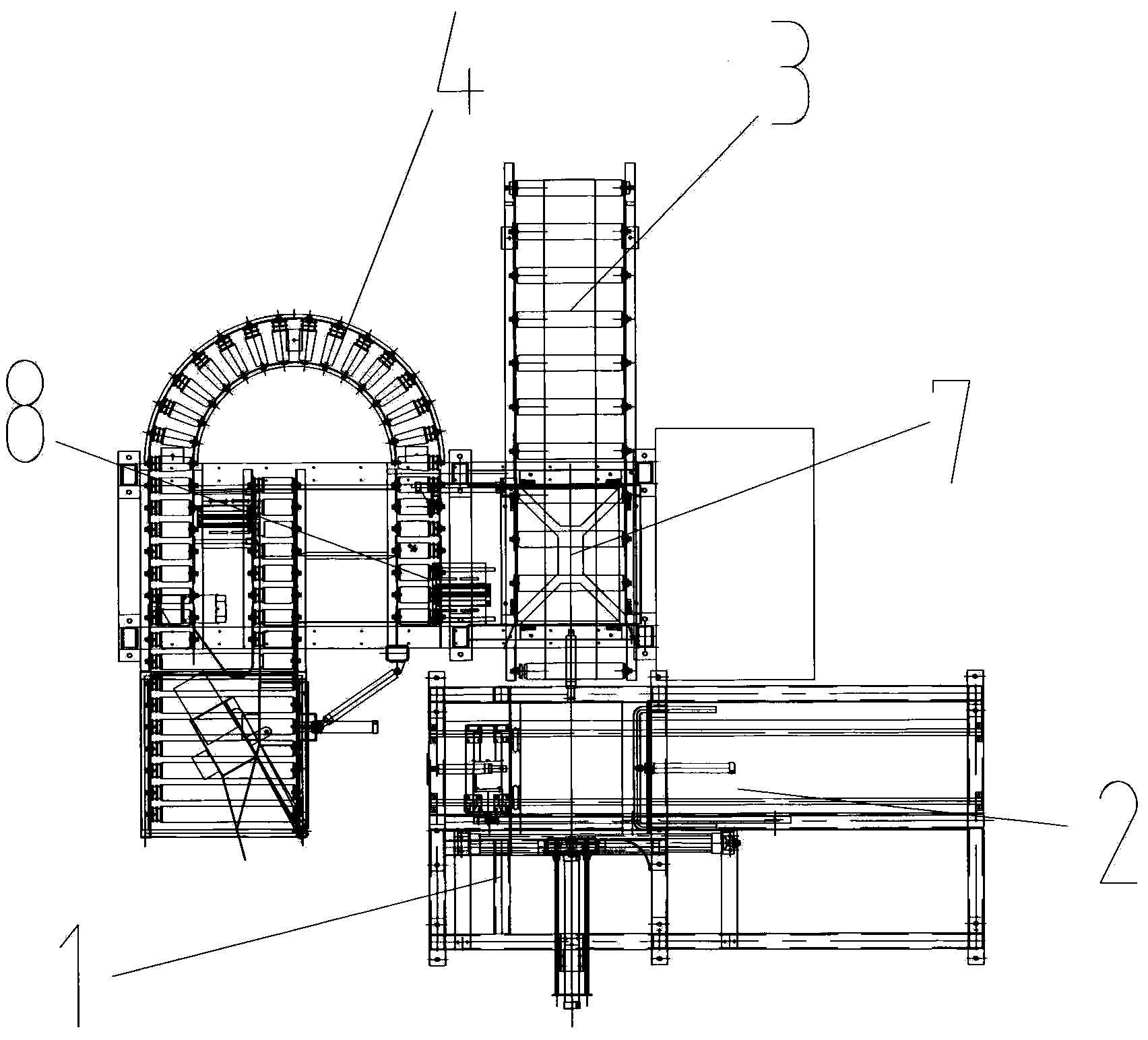

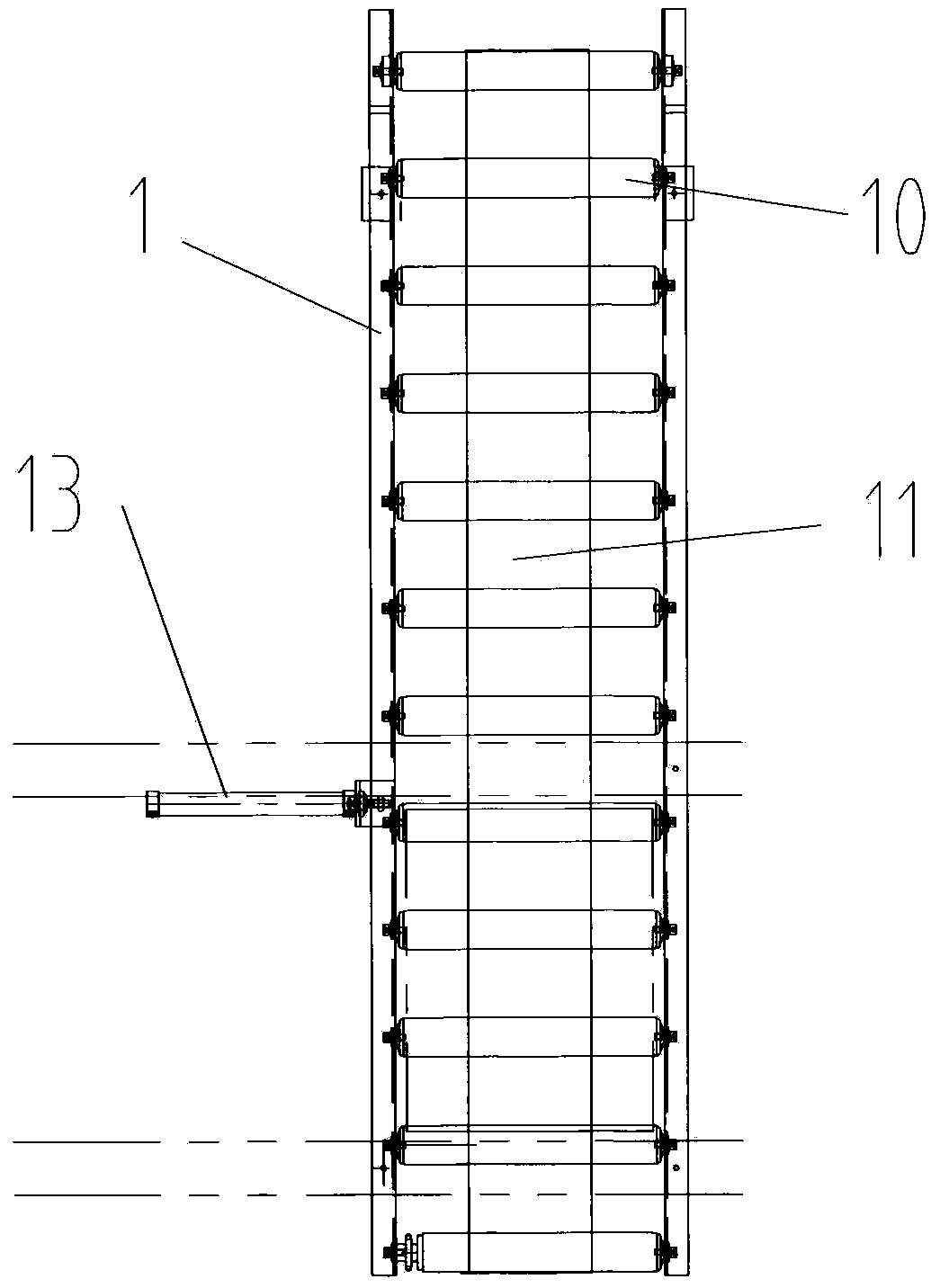

[0023] as attached figure 1 , 2 Described a kind of full-automatic symmetrical box packing machine of the present invention comprises main frame 1, and described main main frame 1 is provided with unpacking device 2 successively, box sending device 3, swing bottle device 4 and walking trolley 5; The walking trolley 5 is fixed with a bottle grasping device 6, and can drive the bottle grasping device 6 to move back and forth between the A part 7 and the B part 8 of the main frame 1; Such products are placed on the B part 8 of the main frame 1 according to a certain rule; the carton feeding device 3 can transport the cartons opened by the unpacking device 2 to the A part 7 of the main frame 1 and suspend them so that the bottle grabbing device can 6. Put the bottle products grabbed from the main frame 1B part 8 into the carton; the box...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap