Slide way threading device

A technology of threading device and slideway, which is applied in the direction of textile, textile and papermaking, handloom, etc. It can solve the problems of tired work, high labor intensity, and increased resistance, and achieve high work efficiency and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment the present invention is further described:

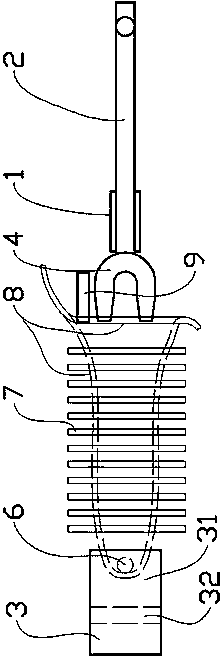

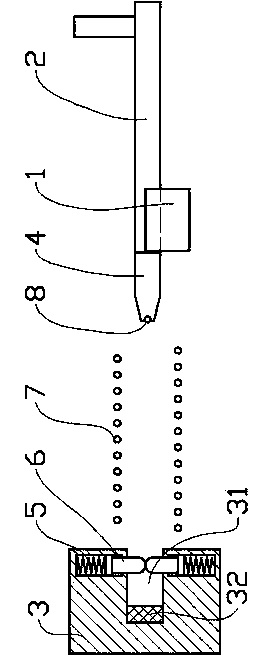

[0011] Such as figure 1 and figure 2 As shown in the embodiment, this slideway threading device includes a slideway 1, a slide rod 2, and a wiring seat 3; the slide rod 2 is assembled in the chute on the upper part of the slideway 1, and the end of the slideway 2 There is a U-shaped incoming wire block 4 extending horizontally, and the two ends of the U-shaped wire incoming block 4 are designed with grooves for holding the weft 8; A horizontal groove 31 is processed on the side facing the sliding rod 2, and the upper and lower ends of the horizontal groove 31 are respectively equipped with retaining blocks 6 vertically tightened by springs 5, and the ends of the retaining blocks 6 are tightened up and down. It is in the shape of an arc; the warp threads 7 to be braided are divided into upper and lower groups and pass between the slideway 1 and the wiring seat 3 to form a staggered open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com