Double hopper device for full-automatic material loading slurry sprayer

A shotcrete machine, fully automatic technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of affecting the construction period, high work intensity, slow feeding speed, etc., to promote civilized construction and improve material preparation. Ability, the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

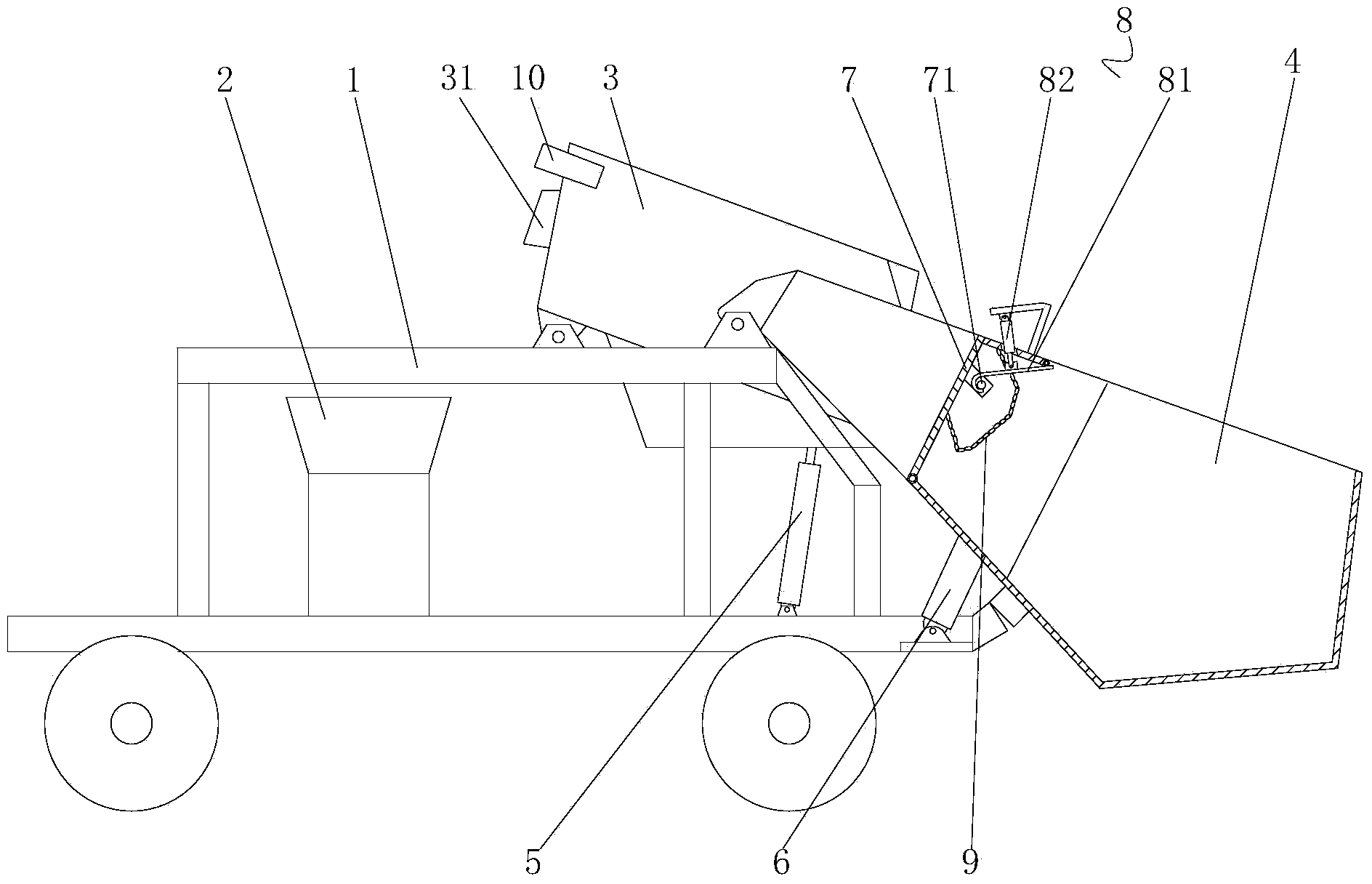

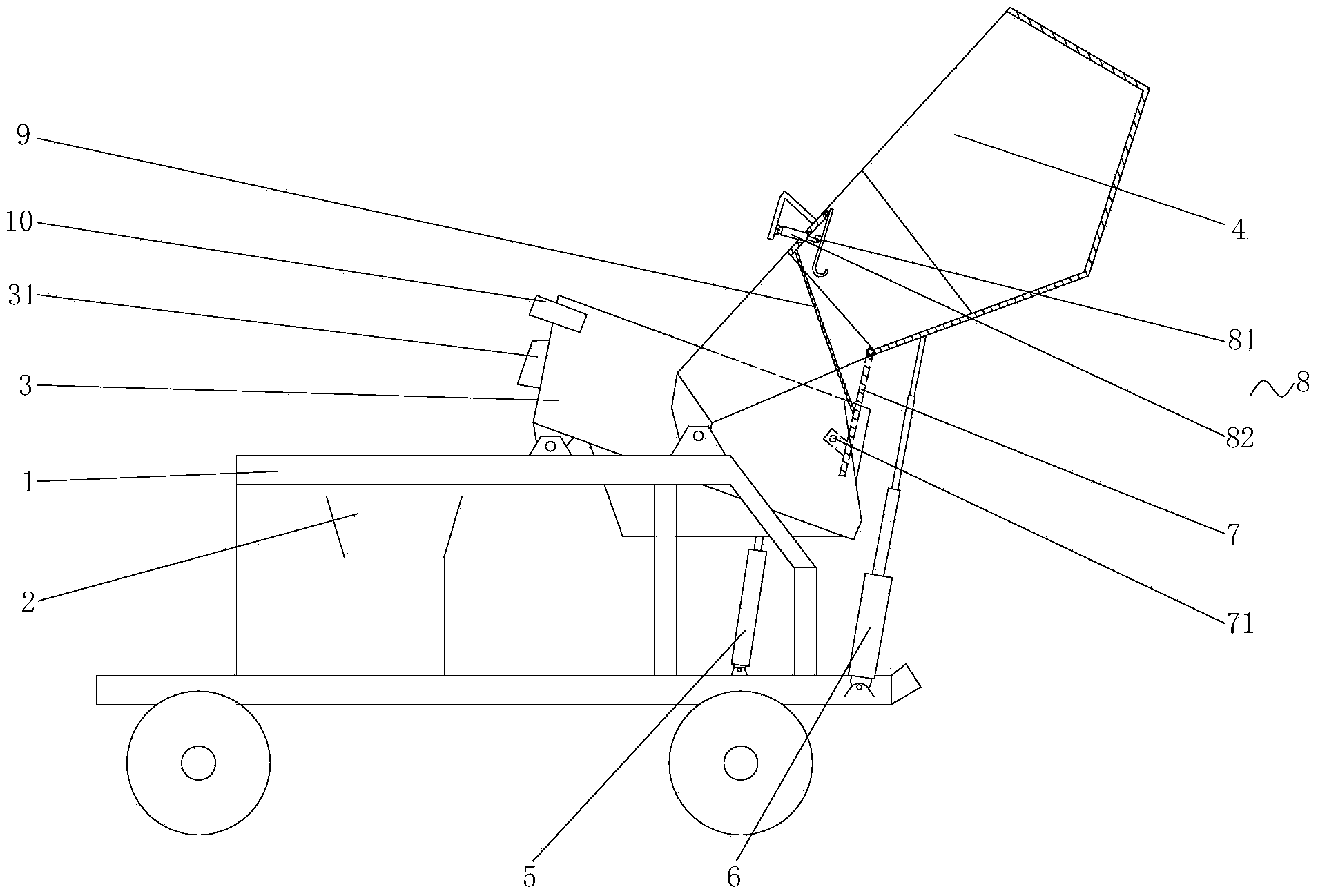

[0013] Such as figure 1 , figure 2 As shown, the double hopper device of the automatic feeding spraying machine of the present invention, the automatic feeding spraying machine includes a vehicle frame 1 and a spraying device 2, and the spraying device 2 is fixed on the vehicle frame 1, and the The double hopper device includes a first hopper 3 and a second hopper 4. Both sides of the bottom of the first hopper 3 are hinged on the vehicle frame 1 and are located at one end of the spraying device 2. The first hopper 3 faces the spraying device 2 is provided with a discharge port 31 on the side wall, the first hopper 3 is turned over by the first oil cylinder, and the first hopper 3 is turned over to the discharge port 31 on its side wall corresponding to the feed of the spraying device 2 When opening the mouth, the raw material outlet 31 in the first hopper 3 flows into the feed port of the spraying device 2; 3 with a gap; the opposite side walls of the second hopper 4 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com