Heat dissipating device with nanometer heat dissipating coating layer and heat dissipating method

A heat-dissipating coating and heat-dissipating device technology, which is applied in the direction of layered products, charging systems, and engine cooling, can solve problems such as shortening, difficulty in achieving expected effects, and power machinery affecting performance, so as to improve combustion efficiency and save energy. The effect of fuel consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

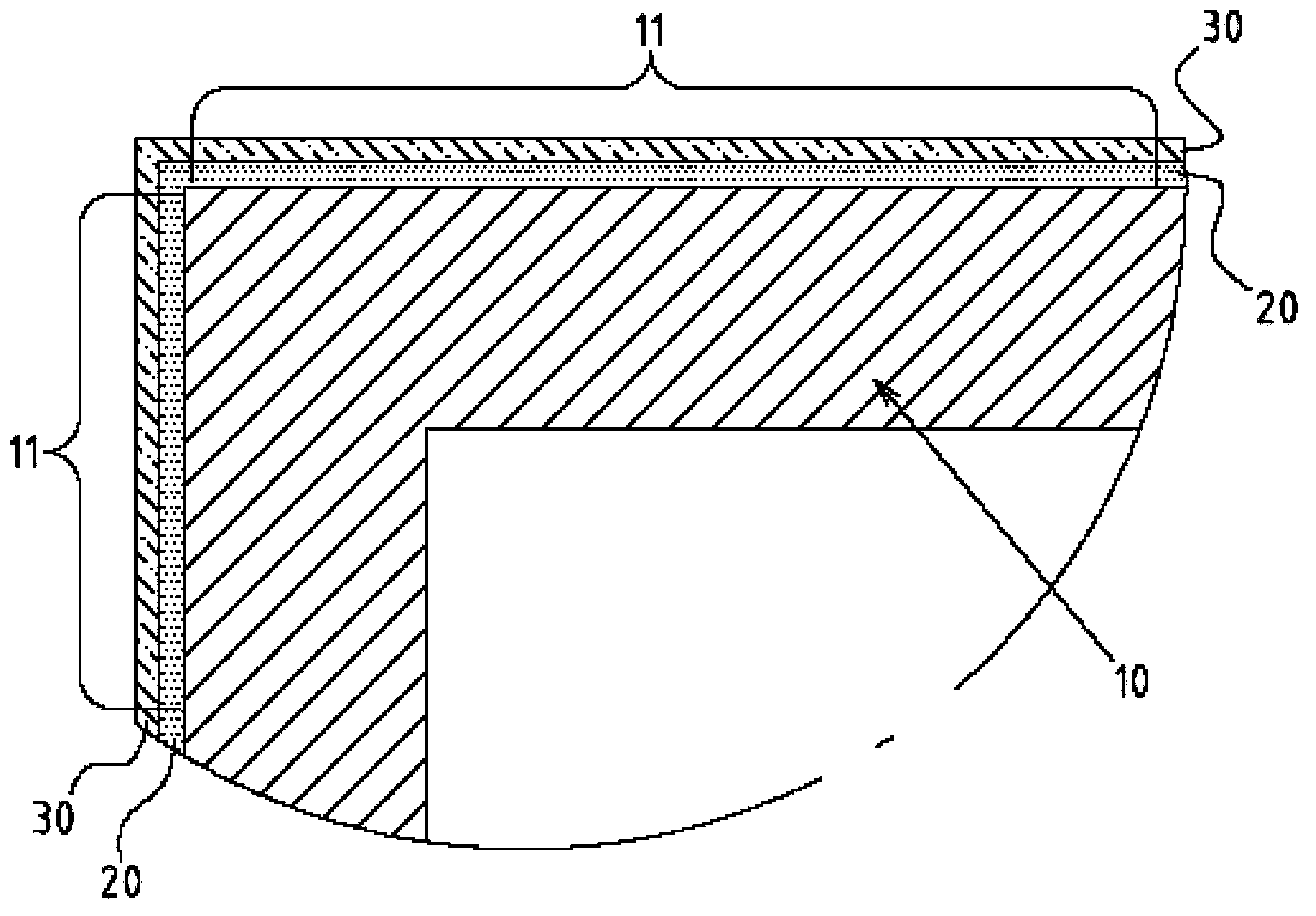

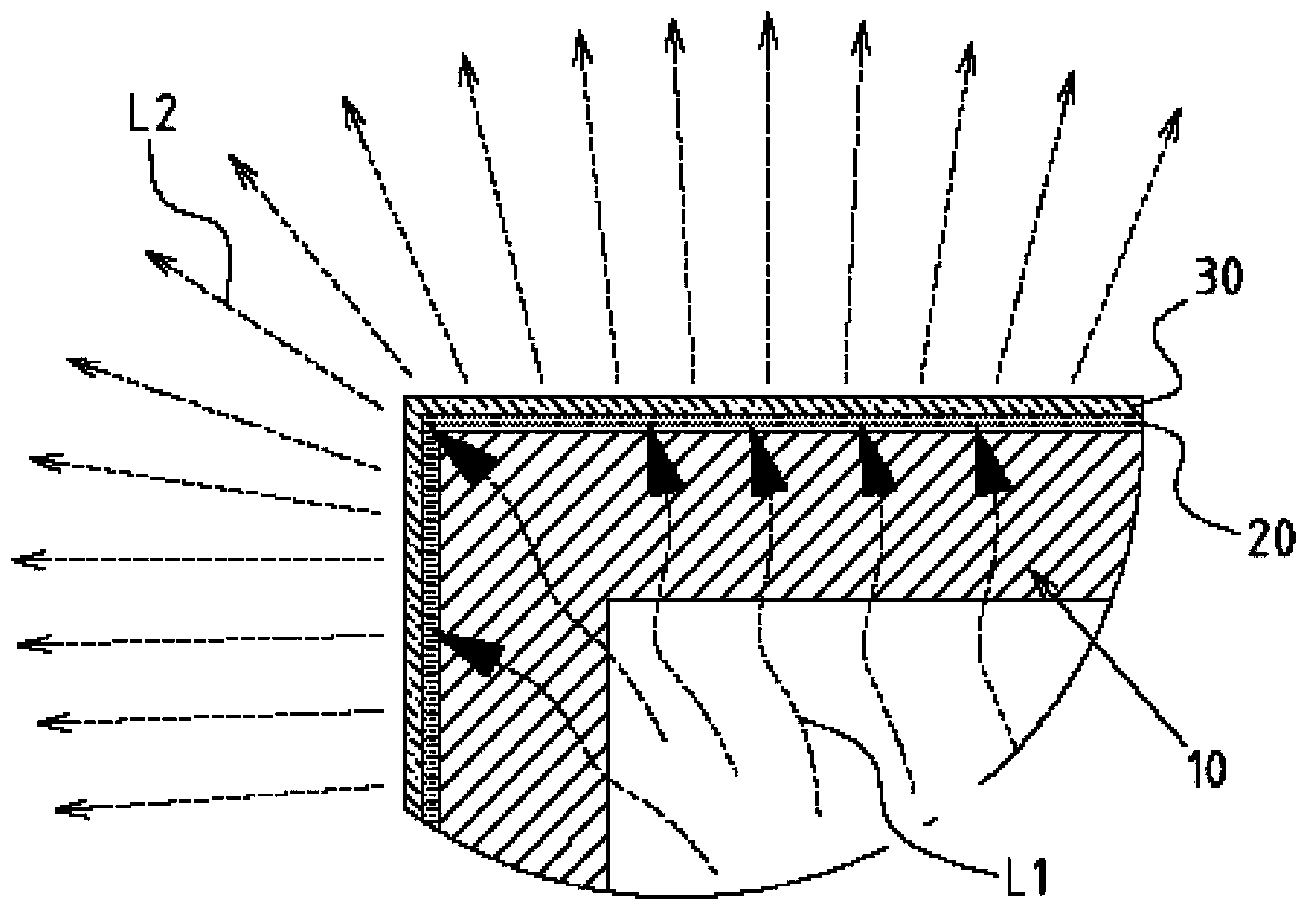

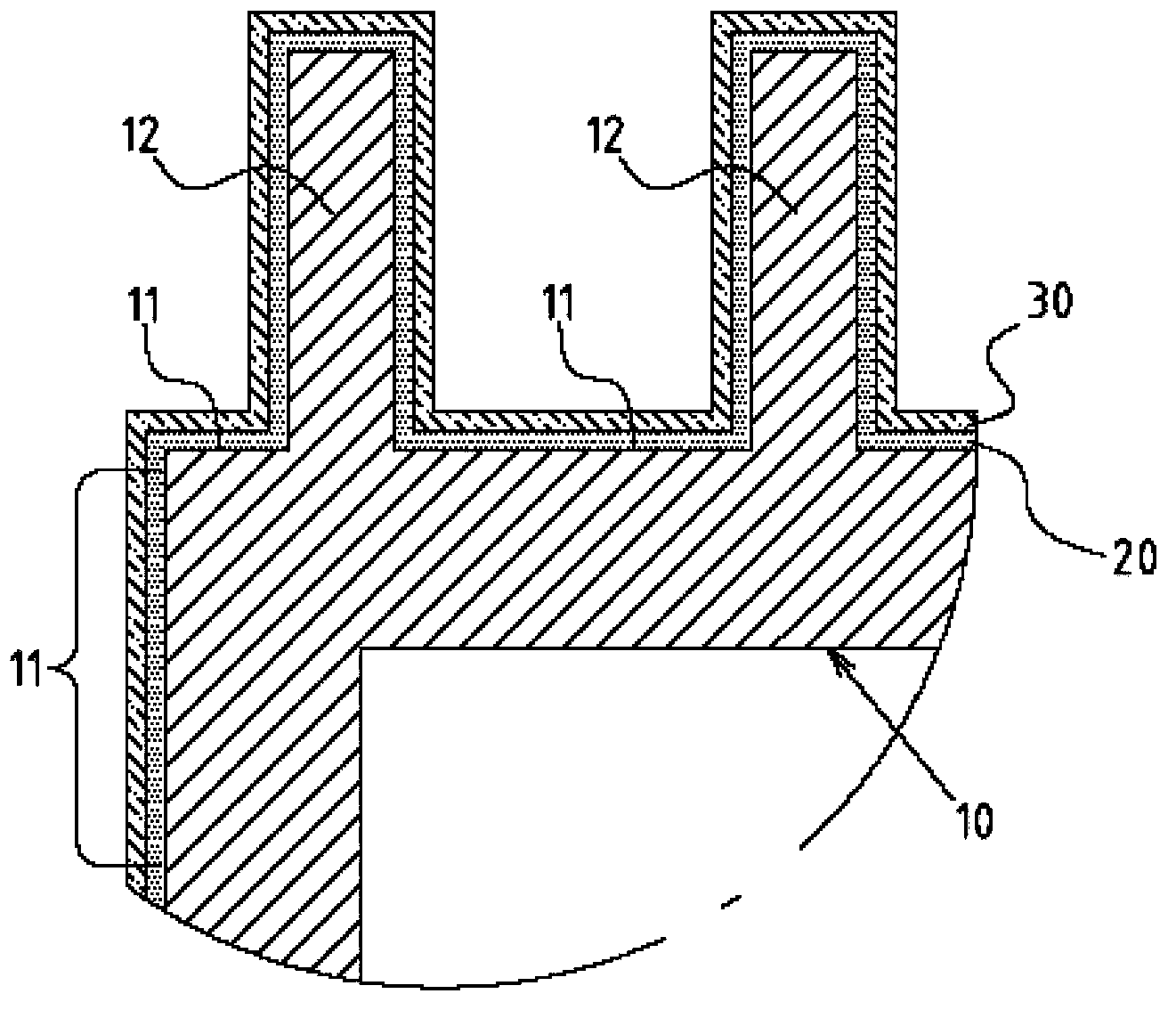

[0015] Such as figure 1 As shown, the present invention has the heat dissipation device of nanometer heat dissipation coating and comprises following composition:

[0016] A device body 10 has at least one heat dissipation area 11 on the outside; wherein the specific implementation shape of the device body 10 is not limited, so in figure 1 Only the partial cross-section of the device body 10 is shown;

[0017] A nanometer heat dissipation coating 20 is directly bonded to at least the surface of the heat dissipation area 11 of the device body 10 by means of coating. The nanometer heat dissipation coating 20 is a heat radiation material, and the heat radiation material includes nano-scale silicon dioxide , antimony dioxide, cobalt dioxide, iron dioxide, copper dioxide, at least one of them mixed with a binder, so that the heat of the device body 10 can be absorbed through the nano heat dissipation coating 20 and Dissipate radially;

[0018] A light-transmitting protective lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com