turbo refrigerator

A technology of turbo refrigerator and turbo compressor, which is applied to refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reduced efficiency of refrigerators, operation of ejectors, inability to effectively utilize the oil recovery function of ejectors, etc. Efficiency improvement, effect of oil recovery function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

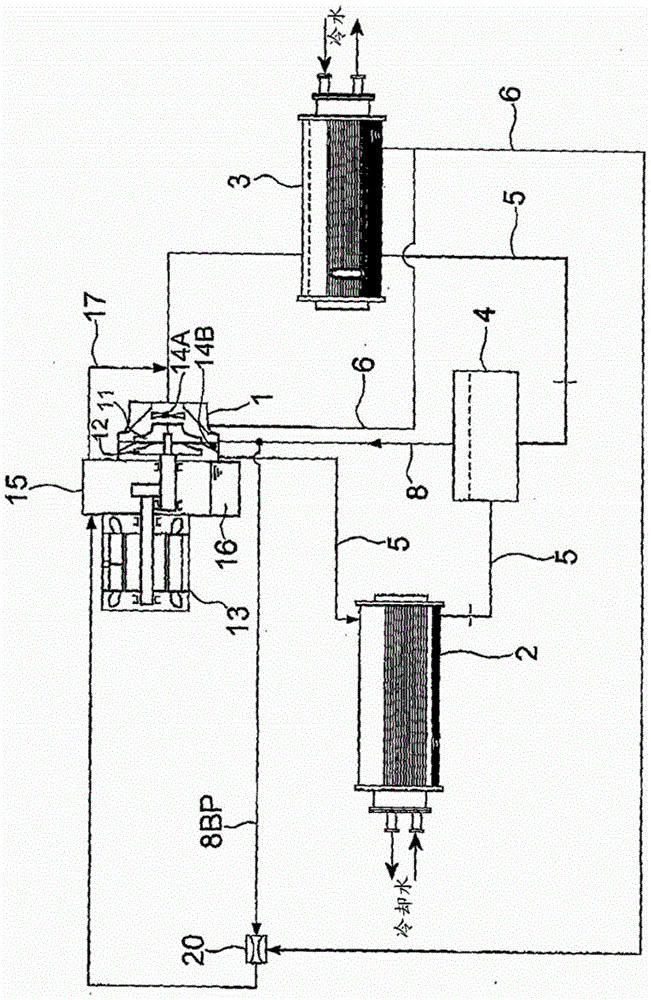

[0031] Below, refer to Figure 1 to Figure 5 Embodiments of the turbo refrigerator of the present invention will be described. exist Figure 1 to Figure 5 In , the same reference numerals are attached to the same or corresponding constituent elements, and overlapping descriptions are omitted.

[0032] figure 1 It is a schematic diagram showing the first embodiment of the turbo refrigerator of the present invention. like figure 1 As shown, the turbo refrigeration mechanism is equipped with: a turbo compressor 1 for compressing refrigerant, a condenser 2 for cooling the compressed refrigerant gas with cooling water (cooling fluid) and condensing it, and cooling water (fluid to be cooled) The evaporator 3 that captures heat and evaporates the refrigerant to exert a cooling effect, and the economizer 4 that is an intercooler arranged between the condenser 2 and the evaporator 3, and the turbo refrigerator passes through the refrigerant piping that circulates the refrigerant 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com