Lubricated machine element and method for lubrication

A technology of mechanical components and lubricating grease, applied in the direction of engine components, mechanical equipment, bearing components, etc., can solve complex and time-consuming problems, achieve the effect of simple relubrication and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

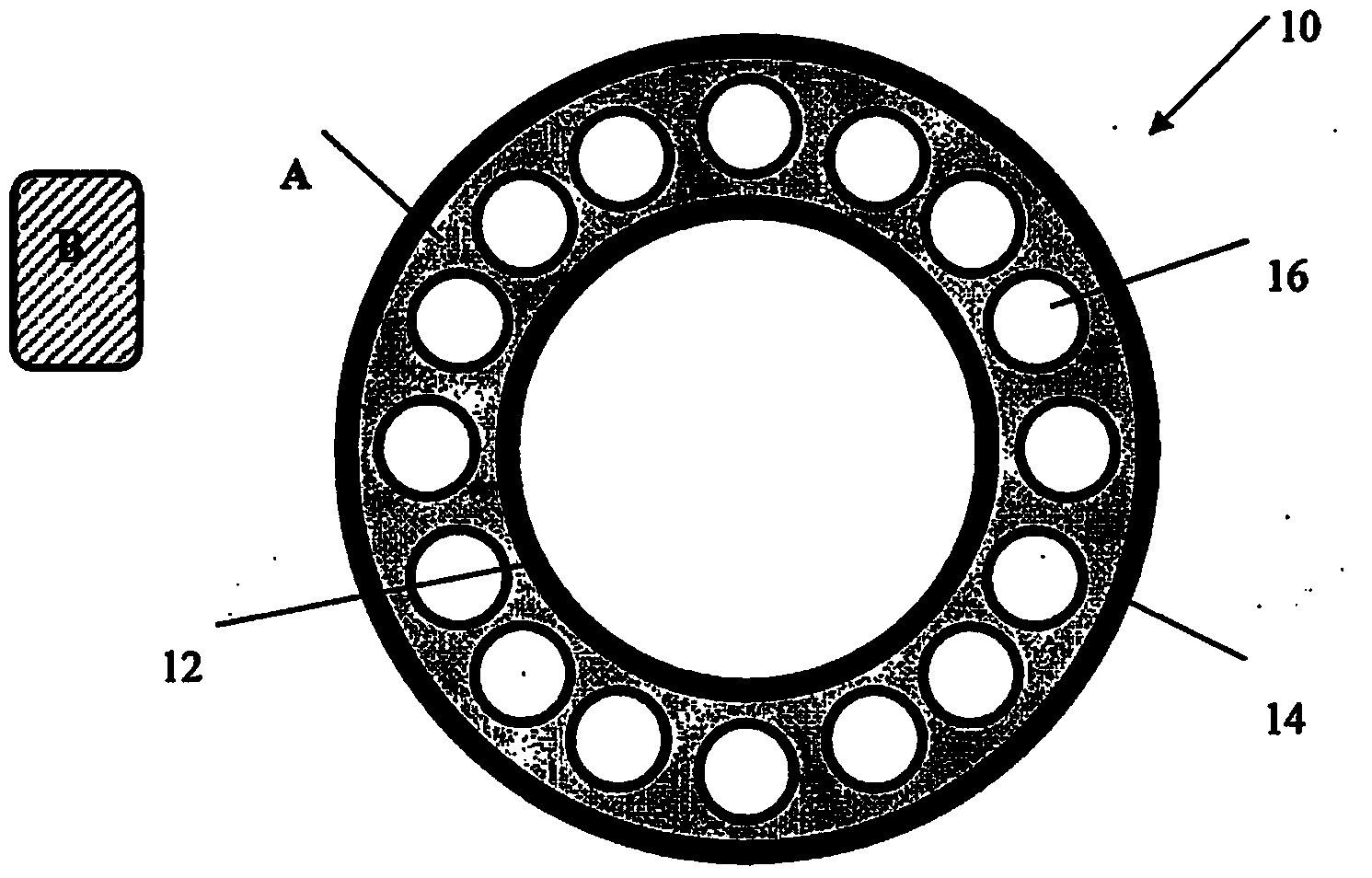

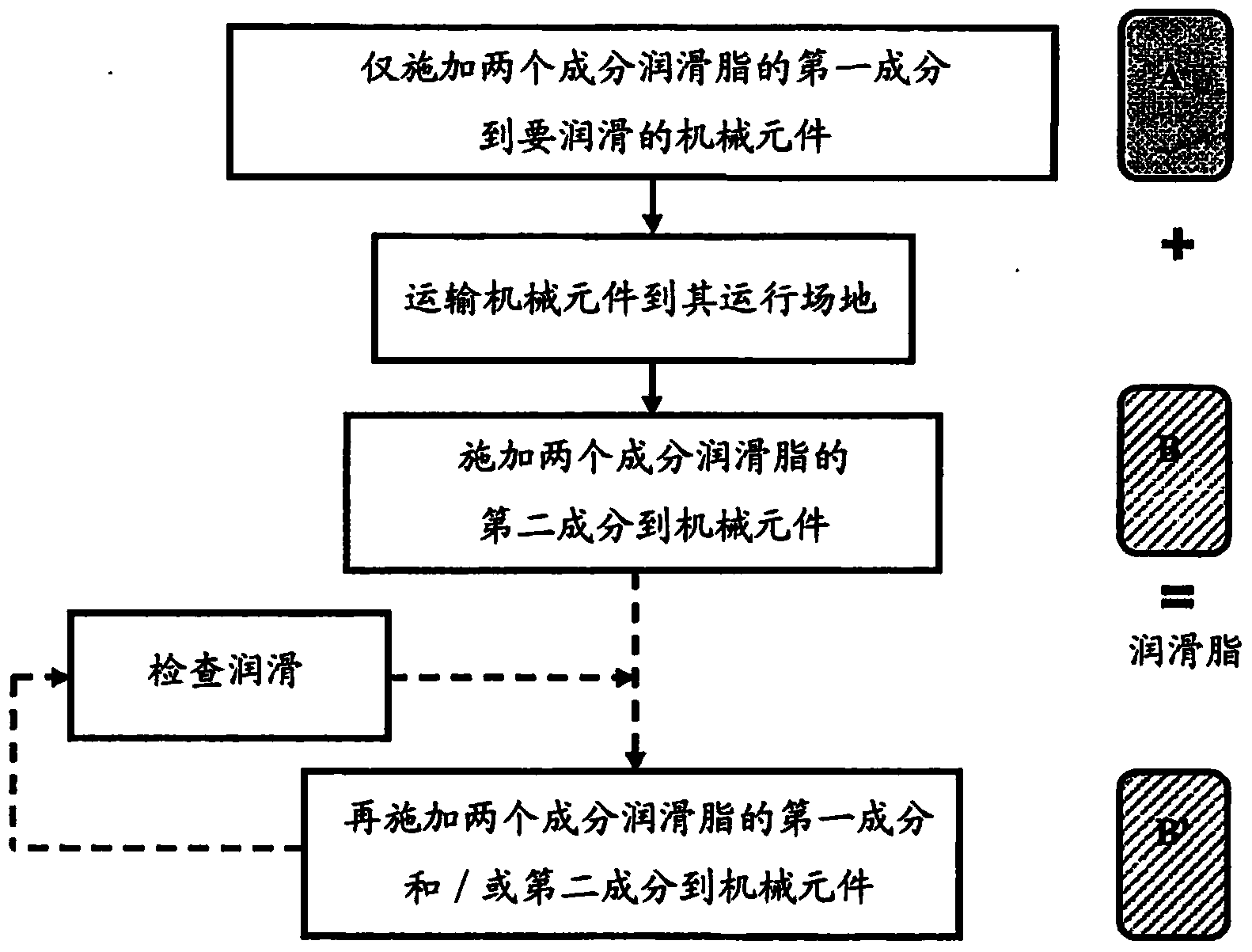

[0036] figure 1 An example of a machine element 10 is schematically shown, namely a rolling element bearing, which may range in size from 10 mm diameter to several meters in diameter, and have a load capacity ranging from tens of grams to several thousand tons. That is, the bearing component 10 can be of any size and have any load capacity. The bearing component 10 has an inner ring 12 , an outer ring 14 and a set of rolling elements 16 .

[0037] Grease must be provided between the rolling elements 16 and the inner ring 12 and outer ring 14 to lubricate the rolling element bearing 10 . Therefore, a two-component grease package is selected based on the bearing's rotational speed, service temperature range, operating noise requirements, relubrication intervals, seals, starting torque, and / or environmental influences.

[0038] The first component A comprises a thickener, such as at least one of the following: polymeric thickener, polypropylene, polyethylene, polyethylene glyco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com