Transmission structure of electric fork truck

A technology of electric forklift and transmission structure, which is applied to vehicle parts, control devices, transportation and packaging, etc. It can solve the problems of high procurement cost and high requirements, and achieve the effect of price reduction, motor, frequency converter and controller simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

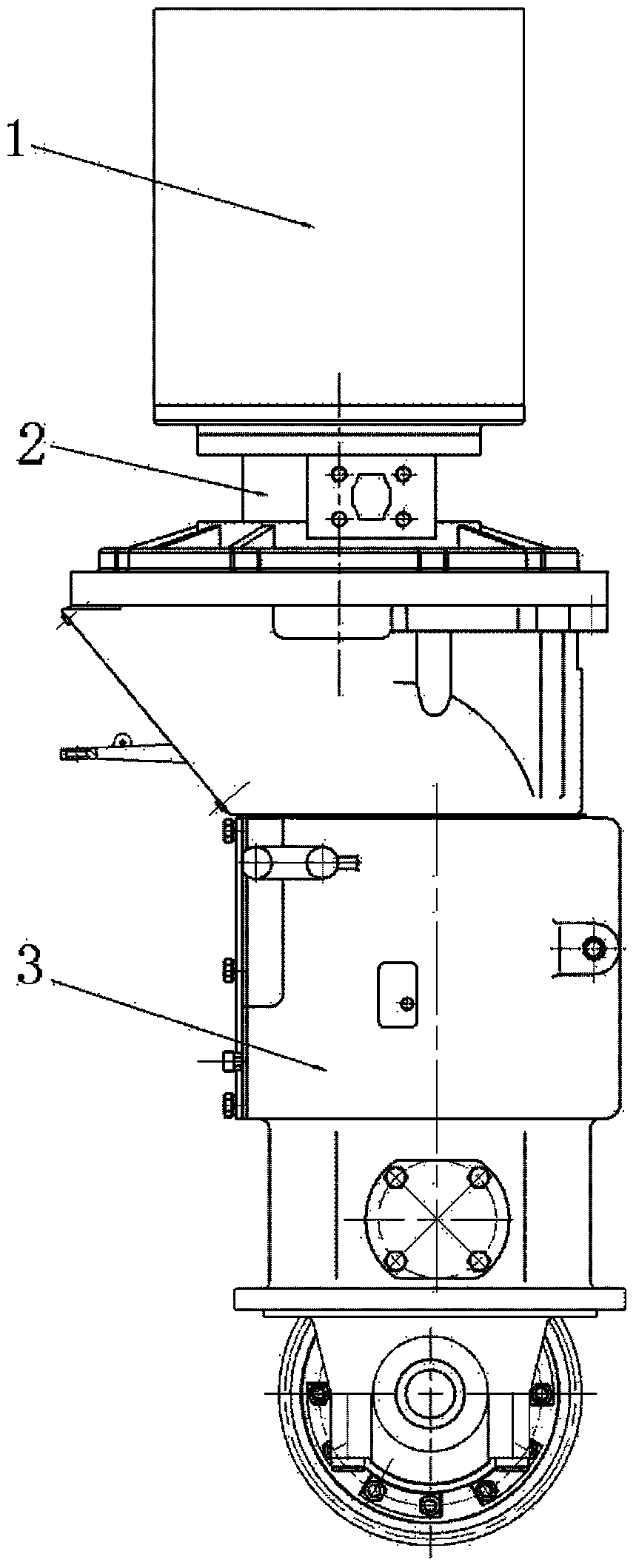

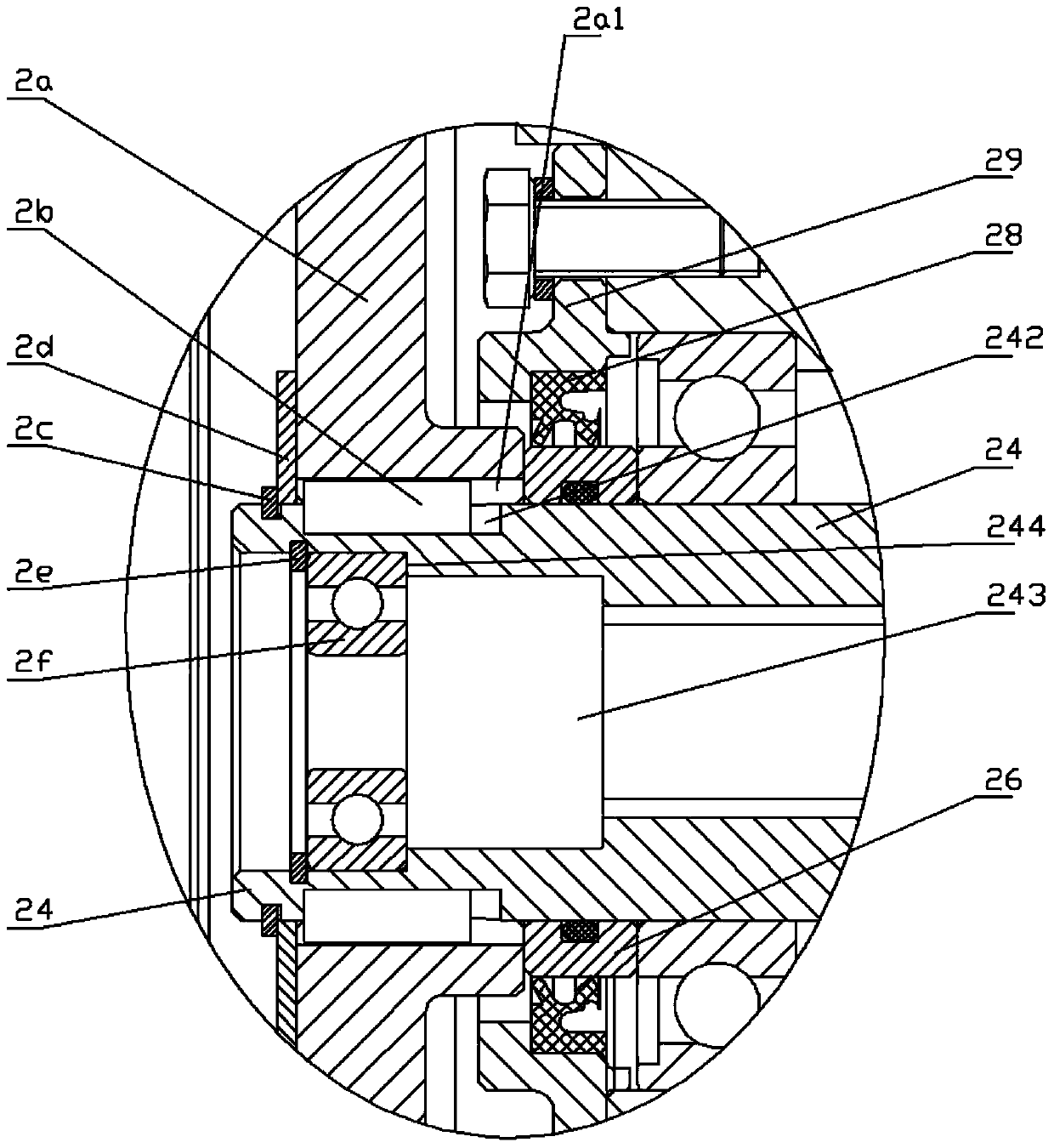

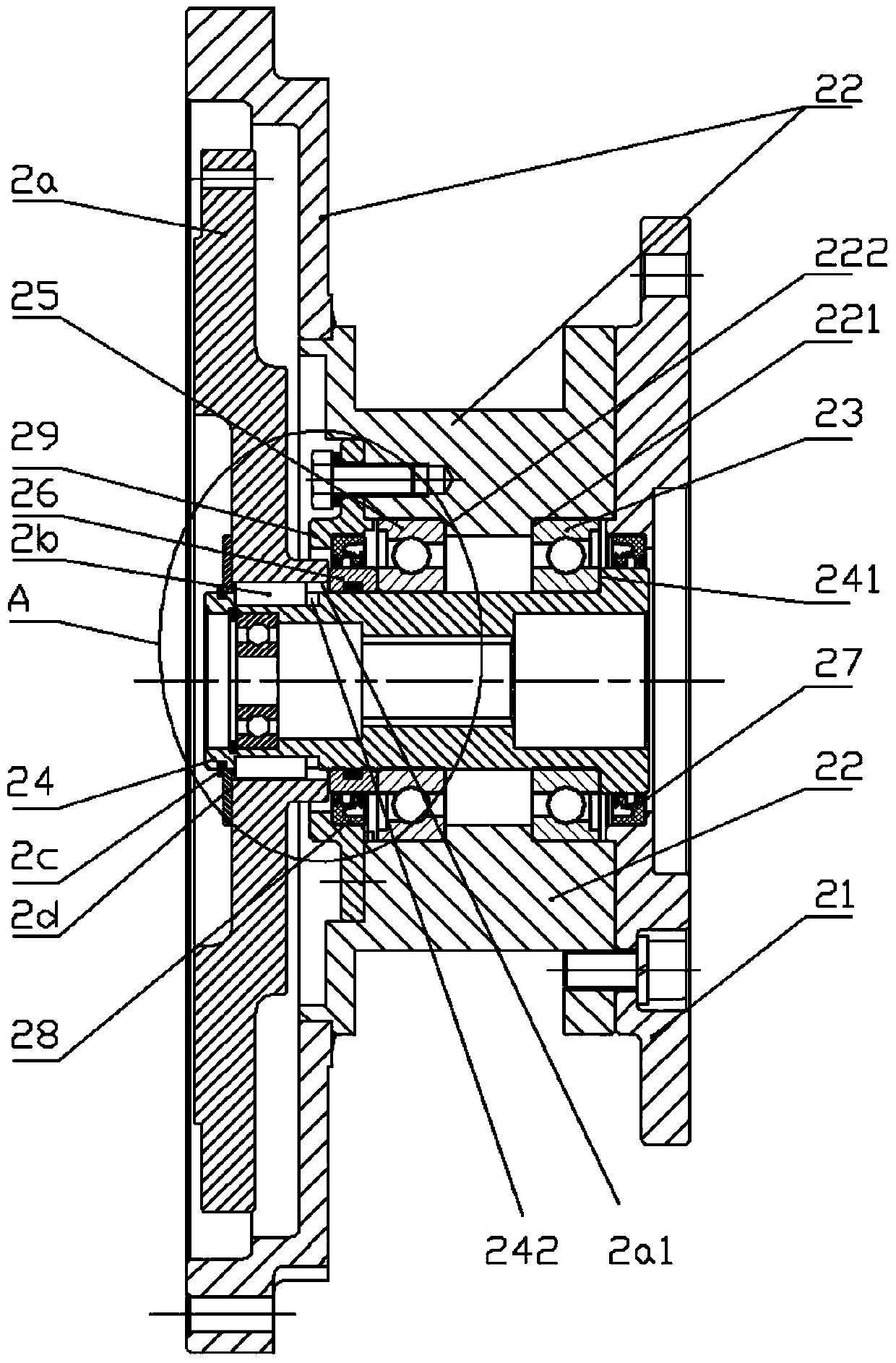

[0016] Example: see Figures 1 to 3 As shown, the transmission structure of the electric forklift includes the motor 1 and the gearbox 3 of the electric forklift, and the structure of the transition connection device 2 is that the connection plate 21, the transition box body 22 and the housing of the motor 1 are fixed and connected together by bolts, The outer rings of the first bearing 23 and the second bearing 25 are fixed on the inner wall of the transition box 22, the inner rings of the first bearing 23 and the second bearing 25 are fixed together with the input shaft 24, and the input shaft 24 is connected with the rotating shaft of the motor 1 fixed together;

[0017] The inner wall of the transition box 22 is formed with a first box step 221 and a second box step 222, the outer ring of the first bearing 23 is pressed on the first box step 221, and the outer ring of the second bearing 25 is pressed on the second step. On the second box body step 222, an input shaft step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com