How to open a barrel of gum rosin

A technology for gum rosin and rosin, which is applied in the field of gum rosin processing equipment manufacturing, can solve the problems of high opening cost and inconvenient opening of barreled gum rosin, and achieves the effects of reducing production cost, saving iron resources and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing implementation:

[0020] The method comprises opening a rosin barrel containing gum rosin, and using a barreled gum rosin can opening device.

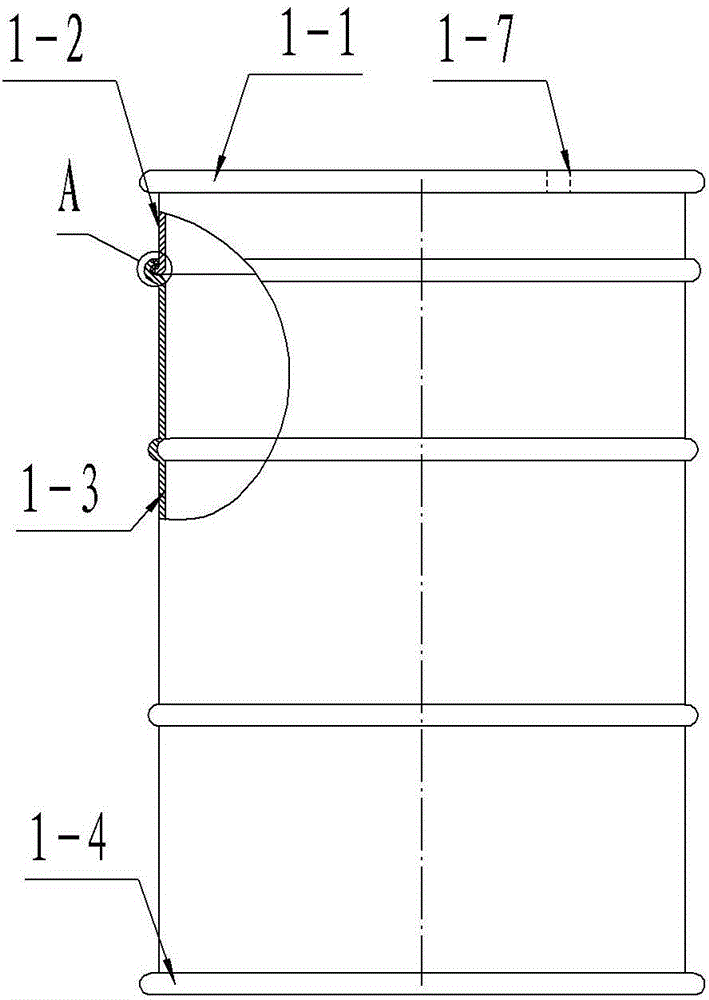

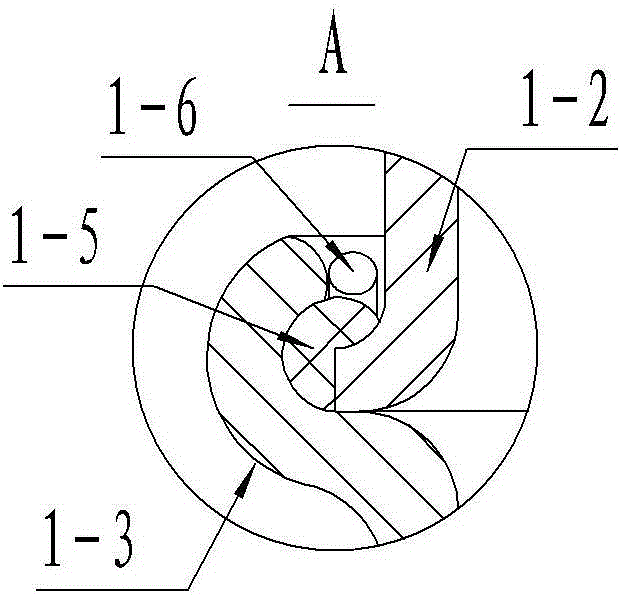

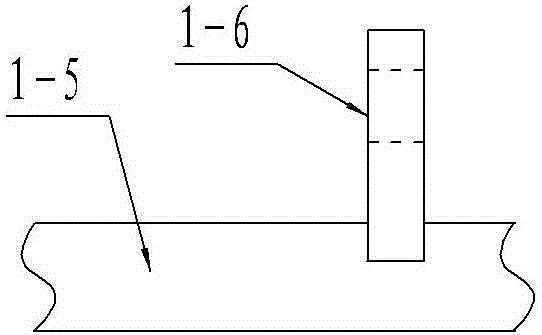

[0021] rosin barrels such as Figure 1 to Figure 3 Shown, comprise the bung 1-1 with injection port, the bung 1-4, and bung 1-3 between bung 1-1 and bung bottom 1-4, bung 1-3 and bung 1-1 is provided with a section of ring body 1-2. The lower end of the ring body 1-2 is provided with an outward flange, and the upper end of the barrel body 1-3 is provided with an outwardly curved curved portion, and the curved portion of the barrel body 1-3 is upward and higher than the ring body 1-2. The top of the flange is bent inwardly to form a ring buckle to wrap the flange of the ring body 1-2, and the edge diameter of the curved part of the barrel body 1-3 is greater than the diameter of the outer edge of the flange of the ring body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com