Stepped wire coil pay-off rack

A stepped and pay-off rack technology, which is applied in the direction of coil manufacturing, electrical components, and conveying filamentous materials, can solve the problems of different traction force, excessive force on the wires, poor stacking flatness of the wires, etc., and achieve dimension damage Improvement of environment, elimination of wire wear, and improvement of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

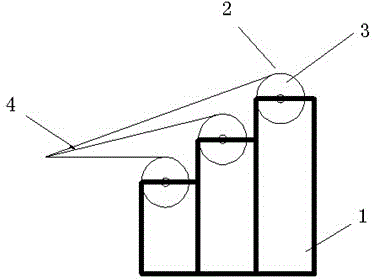

[0010] A stepped reel pay-off rack, the pay-off rack includes a stepped support 1, a pay-off device 2 for installing a reel 3 is provided on each step of the stepped support, and the pay-off device can move left and right set on a stepped stand. The stepped support is provided with three layers of steps, and the heights of the three layers of steps are arranged in equal difference. A group of parallel laying-off devices are horizontally arranged on each step.

[0011] The wire reels are operated separately, and there is no need for multiple wire reels to be connected in series to operate as a whole, which greatly improves the safety. A ladder-type pay-off frame is adopted, multiple wire reels are placed in parallel, multiple wires 4 are gathered and stacked along a straight line, and multiple wire reels are paid off individually, with uniform traction.

[0012] The use of the invention basically eliminates wire wear, greatly improves the flatness of wire superimposition; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com