Back pressure automatic lock controller

A lock controller and automatic technology, applied in electrical components, emergency protection circuit devices, etc., can solve problems such as personal electric shock death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

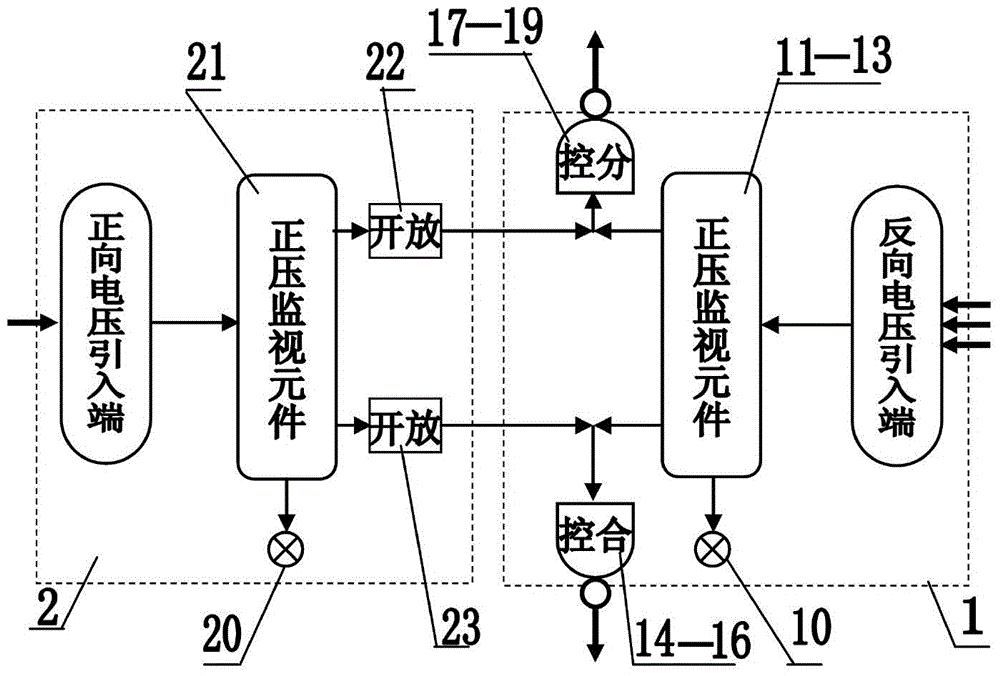

Method used

Image

Examples

specific Embodiment approach 1

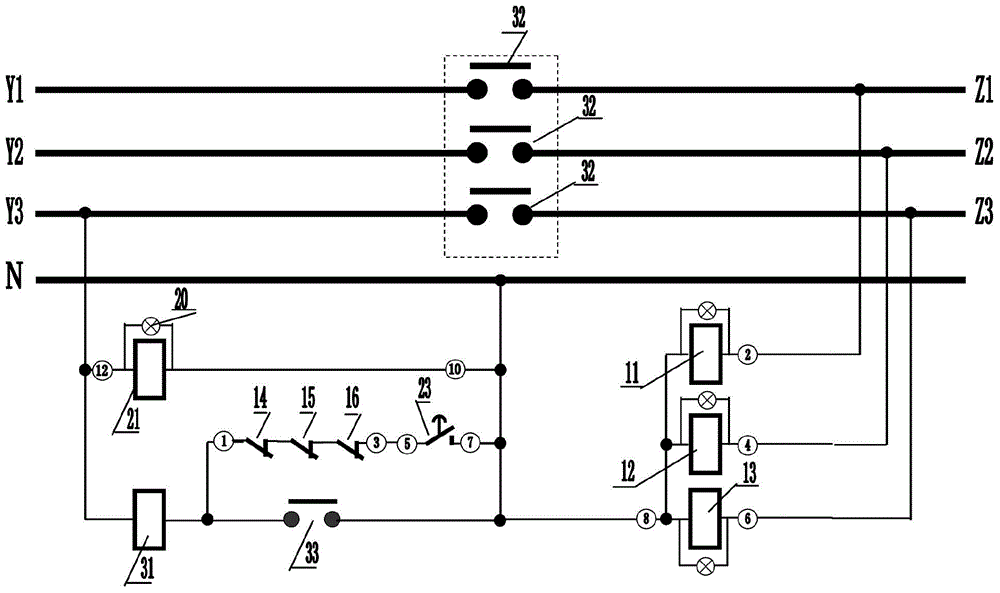

[0050] Specific implementation mode one, such as image 3 and Figure 5 As shown, when the low-voltage switch is an AC contactor 3 , the AC contactor 3 mainly includes: an AC contactor closing coil 31 , three AC contactor main contacts 32 , and an AC contactor normally open auxiliary contact 33 . The terminals ②, ④, ⑥ of the three phase-separated voltage measuring relays 11, 12, 13 of the locking controller of the present invention are respectively connected to the load users of the low-voltage power distribution lines controlled by the main contacts 32 of the three AC contactors In the voltage circuit of each phase on the side, it is used to measure the reverse voltage. The common terminal ⑧ of the three phase-separated voltage measurement relays 11, 12, and 13 is connected to the zero phase; the terminal of the voltage monitoring delay relay 21 It is directly connected to the one-phase voltage circuit on the side of the distribution transformer, and the other terminal ⑩ of...

specific Embodiment approach 2

[0058] Specific Embodiment 2. The feedback voltage measurement locking logic of the locking controller of the present invention can be designed in the smart circuit breaker 4 as an extended application of the protection function, and its electrical wiring or logical relationship will be attributed to the internal principle of the smart circuit breaker at the same time wiring or smart protection logic. Such as Figure 4 As shown, when the low-voltage switch is an intelligent circuit breaker 4, the intelligent circuit breaker 4 mainly includes: an intelligent circuit breaker closing coil 41, an intelligent circuit breaker opening coil 42, three intelligent circuit breaker main contacts 43, and an intelligent circuit breaker normally The auxiliary contact 44 is opened, and the auxiliary contact 45 of the intelligent circuit breaker is normally closed. The working voltage circuit of the smart circuit breaker 4 is determined by the component manufacturer, for the convenience of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com