Fluorine resin film

A fluororesin and blue pigment technology, applied in the field of fluororesin film, can solve the problems of reduced visible light transmittance, poor visible light transmittance, poor transparency, etc., and achieves excellent colorless transparency and heat ray blocking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

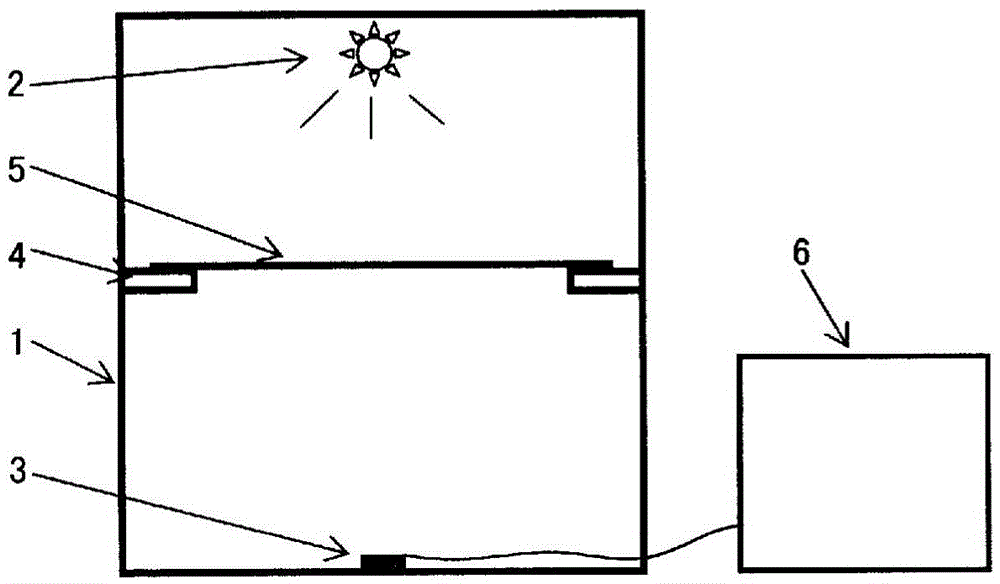

Image

Examples

Embodiment 1

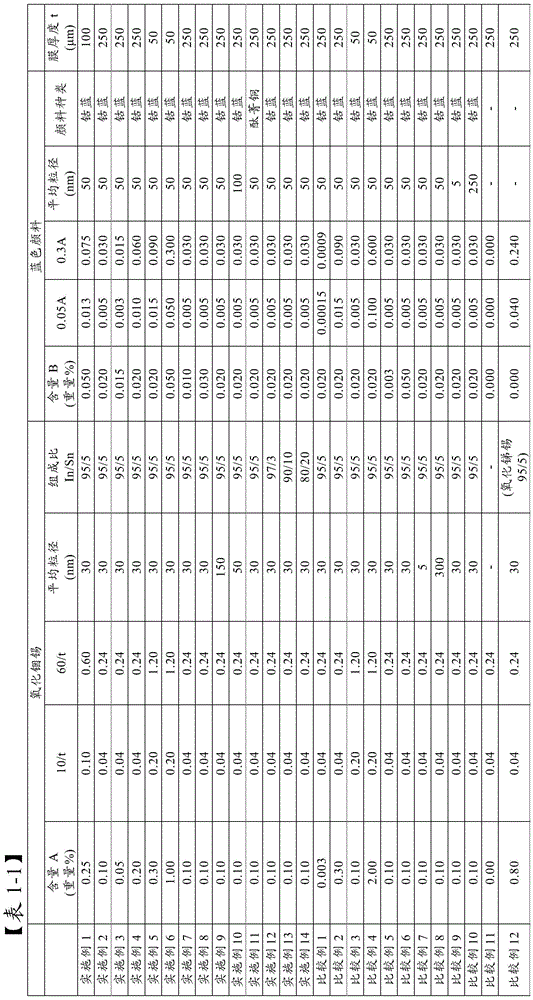

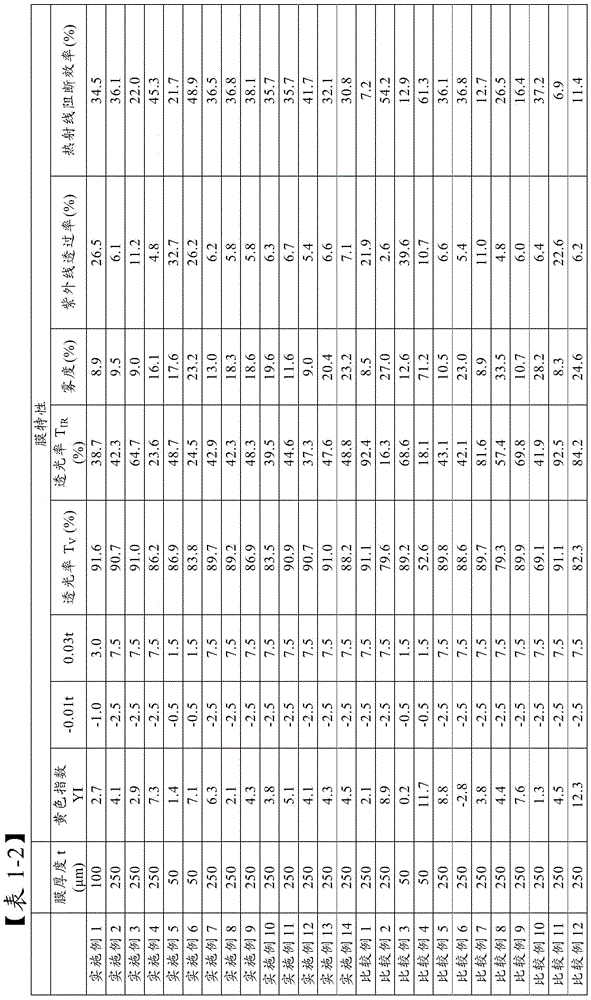

[0097] ETFE particles: 462.5kg, ITO masterbatch A1: 25kg and blue masterbatch B1: 12.5kg were uniformly mixed, supplied to a single screw extruder with a screw diameter of 65mm, filtered with a filter, and then at 330°C Extruded into a film with a T-die, and contacted with a cooling roll set at 175°C to cool and solidify and wind to obtain a thickness of 100μm with ITO content of 0.25% by weight and cobalt blue content of 0.050% by weight Of unstretched film.

[0098] The obtained film has no yellowish tint, is colorless and transparent, and the outdoor scenery passing through the film looks natural and has good perspective. The near-infrared transmittance of this film is low at 38.7%, and the heat ray blocking efficiency measured by a heat ray blocking evaluation tester is 34.5%. The UV transmittance is reduced to 26.5%, which is a film with UV blocking effect. Table 1 summarizes the film properties.

Embodiment 2

[0100] Using the same raw materials as those used in Example 1, ETFE particles: 485kg, ITO masterbatch A1: 10kg, and blue masterbatch B1: 5kg were uniformly mixed and supplied to a single screw extruder with a screw diameter of 65mm. The film forming device of the filter, T-die, and cooling cylinder was used to form a film by melt extrusion to obtain an unstretched film having a thickness of 250 μm with an ITO content of 0.10% by weight and a cobalt blue content of 0.020% by weight.

[0101] The obtained film has no yellowish tint, is colorless and transparent, and the outdoor scenery passing through the film looks almost natural in color, and has good perspective. The near-infrared transmittance of this film is low at 42.3%, and the heat ray blocking efficiency measured by a heat ray blocking evaluation tester is 36.1%. The UV transmittance is significantly reduced to 6.1%, which is a film with UV blocking effect. Table 1 summarizes the film properties. In addition, after the ...

Embodiment 3、4

[0102] [Examples 3 and 4, Comparative Examples 1 and 2]

[0103] Except for variously changing the compounding quantity of the ITO masterbatch, it carried out similarly to Example 2, and obtained the unstretched film with a thickness of 250 micrometers.

[0104] The film characteristics are summarized in Table 1. The more the ITO content in the film, the lower the average light transmittance at 1800-2200 nm, and the heat ray blocking efficiency increases inversely. If the ITO content is 0.003% by weight (Comparative Example 1), the near infrared transmittance is high, reaching 92.4%, and the heat ray blocking efficiency is insufficient, being 7.2%. If the ITO content is 0.30% by weight (Comparative Example 2), although it can be said that there is a heat ray blocking effect in this case, the haze is high, reaching 27.0%, and the transparency is insufficient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com