Goods sorting device, goods sorting method and optical element manufacturing device

A classification device, classification method technology, applied in chemical instruments and methods, classification, solid separation and other directions, can solve complex and complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

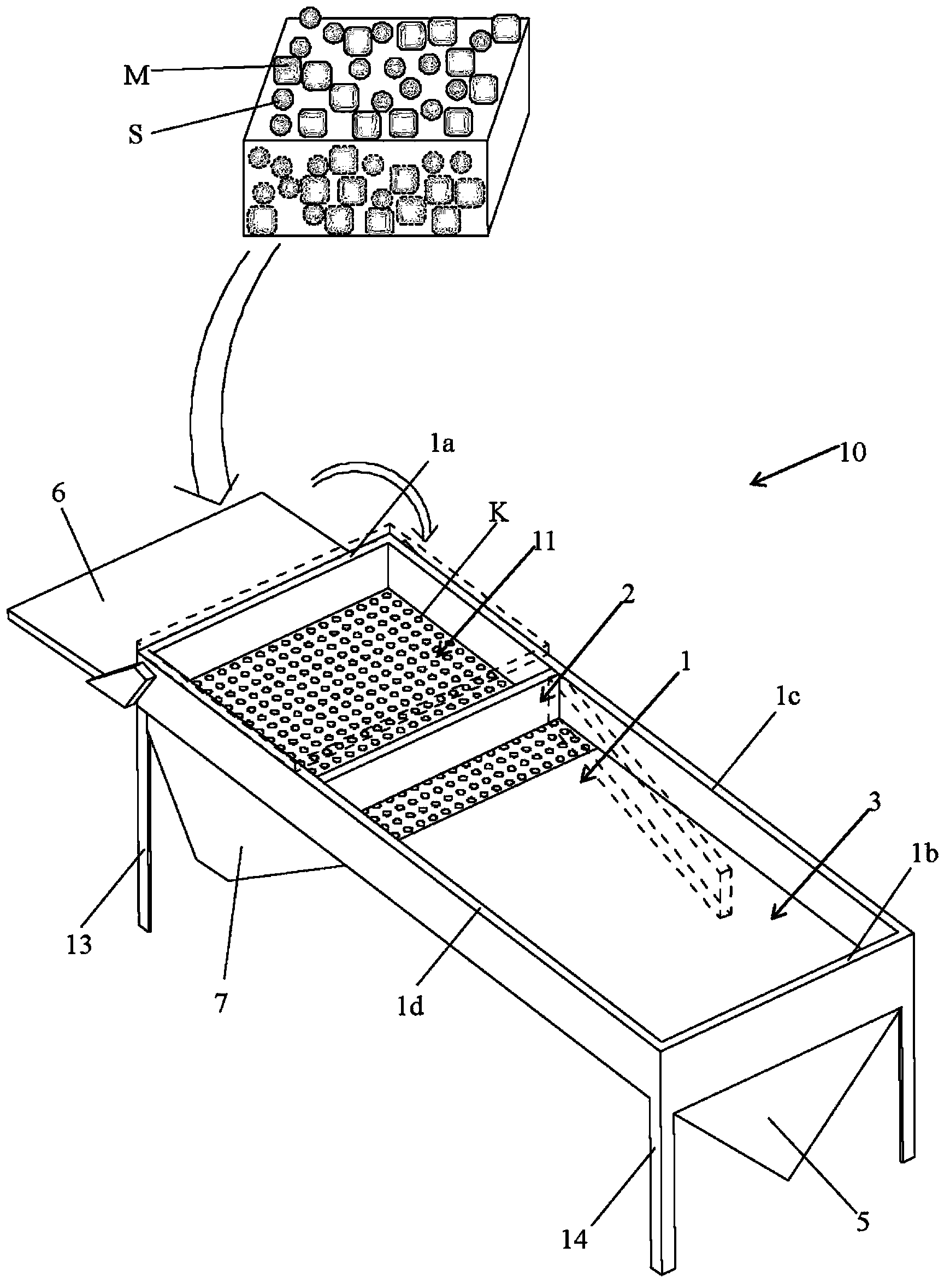

[0032] figure 1 It is an overall perspective view of the sorting device 10 according to one embodiment of the present invention. Figure 2 is used figure 1 A diagram of the order of the sorting method of the sorting device 10. image 3 It is a diagram showing the process of polishing the object to be polished.

[0033] 【Item sorting device】

[0034] The article classification device 10 is used to classify the first article, the second article and the third article with different characteristics. Wherein, the rolling resistance and / or frictional force between the first article and the inclined portion 1 described later is greater than the rolling resistance and / or frictional force between the second article and the inclined portion 1 described later, and the maximum diameter of the third article is smaller than The maximum diameters of the first article and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com