Chain tool container

A tool and chain technology, applied in the field of automatic tool changing devices, can solve problems such as large number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

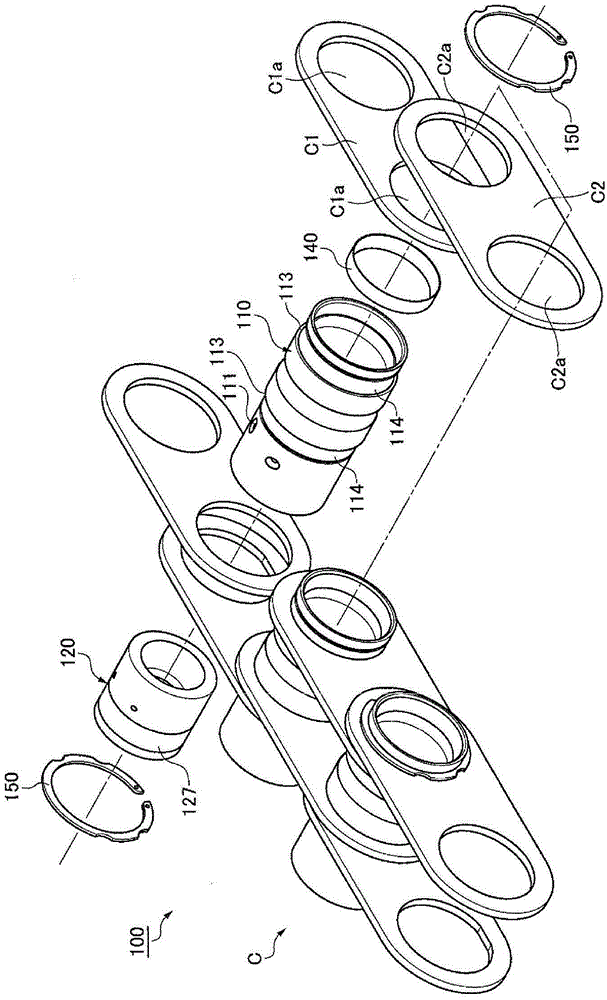

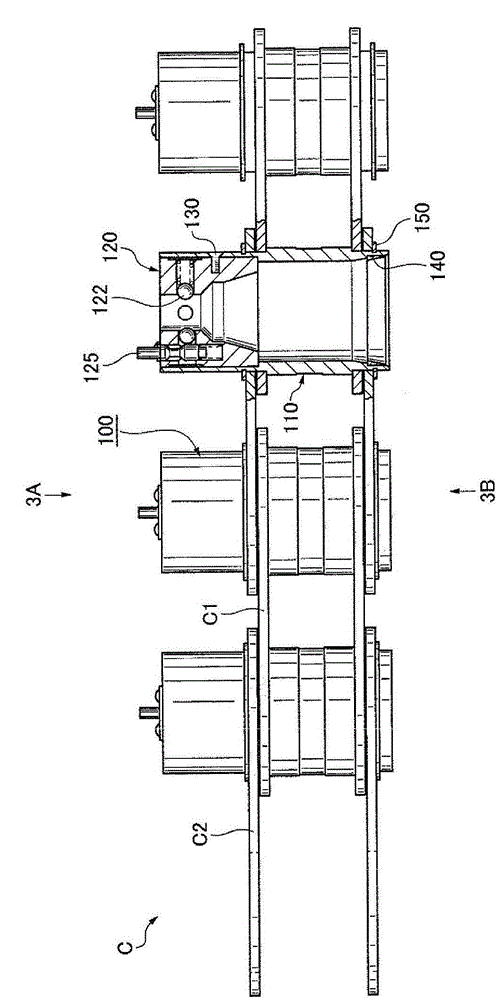

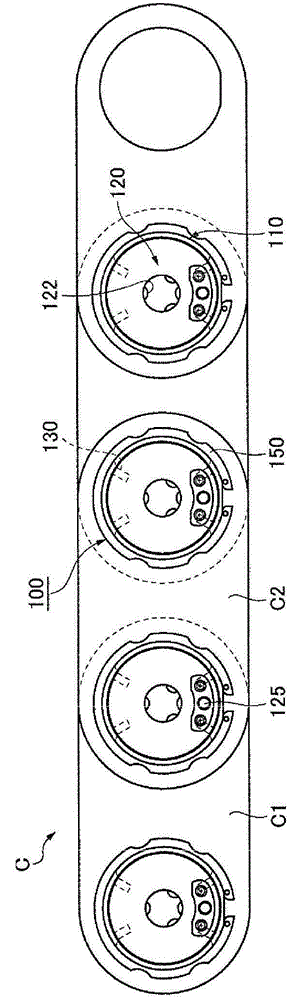

[0080] Below, refer to Figure 1 to Figure 5(C) , FIG. 5(B), and FIG. 5(C) to illustrate an embodiment of the present invention, that is, a tool holder 100 for a chain.

[0081] The embodiment of the present invention is that the tool barrel 100 for the chain is as Figure 1 to Figure 3(A) , as shown in FIG. 3(B), a tool holding unit 120 is provided, and the tool holding unit 120 holds the tool T detachably inside cylindrical hollow pin shafts 110, and the cylindrical hollow pin shafts 110 alternately A pair of inner panels C1 and a pair of outer panels C2 are connected.

[0082] Specifically, the chain C has: a pair of inner plates C1 spaced apart in the left and right width direction relative to the chain length direction; a pair of outer plates C2 arranged on the left and right outer sides of the pair of inner plates C1; and a hollow pin 110 .

[0083] Both sides of the hollow pin 110 are inserted through the insertion hole C1a of the inner panel C1 and the insertion hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com