Target assembly

A technology of target components and insulating plates, which is applied in the field of target components, can solve the problems of difficult removal of insulating material films and inconvenient reuse of backplanes, and achieve the effects of easy reuse and suppression of abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

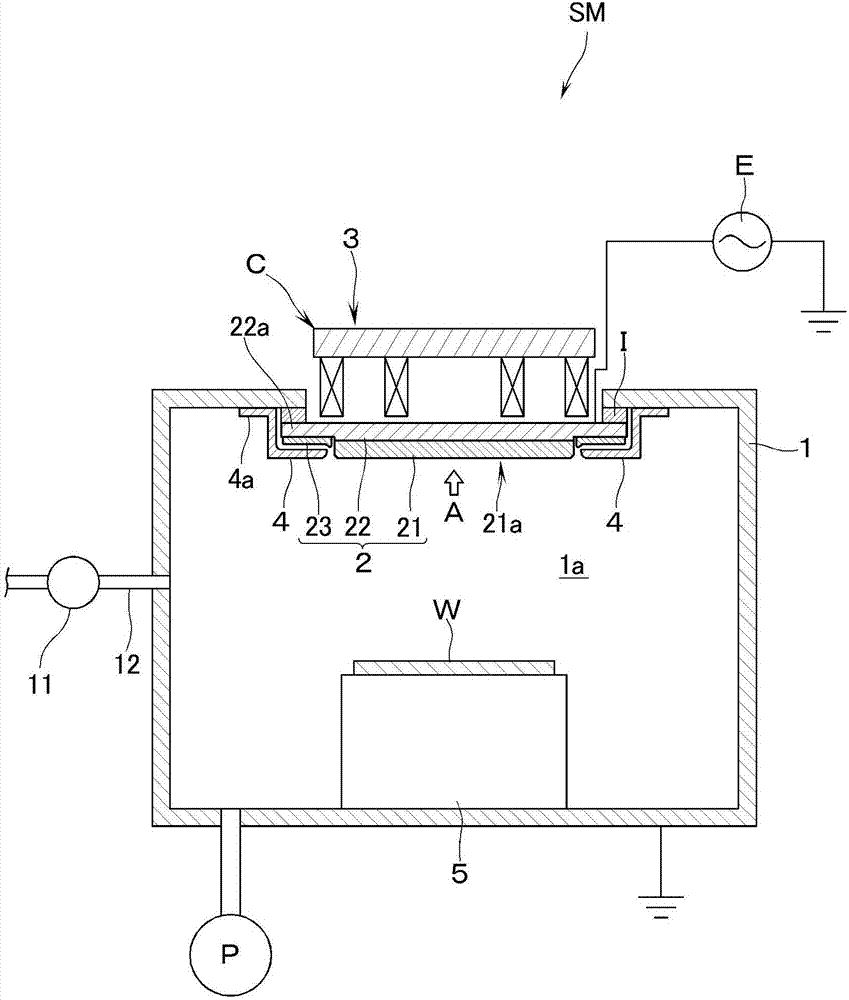

[0023] Hereinafter, referring to the drawings, a target assembly according to an embodiment of the present invention will be described by taking a product mounted on a sputtering apparatus as an example. Below to figure 1 As a reference, the inside top side of the vacuum chamber 1 is described as "upper" and the bottom side thereof as "lower".

[0024] Such as figure 1 As shown, the sputtering apparatus SM has a vacuum chamber 1 defining a process chamber 1a. The bottom of the vacuum chamber 1 is connected to a vacuum pump P made of a turbomolecular pump or a rotary pump through an exhaust pipe, and can be evacuated to a specified pressure (for example, 10 -5 Pa). A gas pipe 12 connected to a gas source not shown in the figure and having a mass flow controller 11 inserted therein is connected to the side wall of the vacuum chamber 1, and a sputtering gas composed of a rare gas such as Ar can be introduced into the processing chamber 1a at a predetermined flow rate. .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com