Method for producing an air guide for a suspension arm and suspension arm with an air guide

A technology of a guide device and a control arm, which is applied to the cantilever mounted on the pivot, the brake, the cooling brake, etc., can solve the problem of reduced rigidity, and achieve the effect of good rigidity characteristics, reasonable cost, and small processing overhead.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

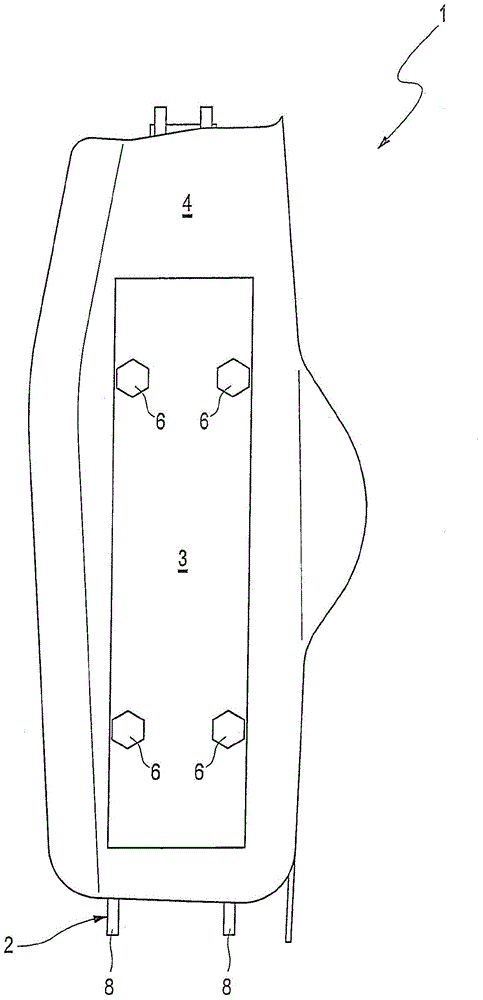

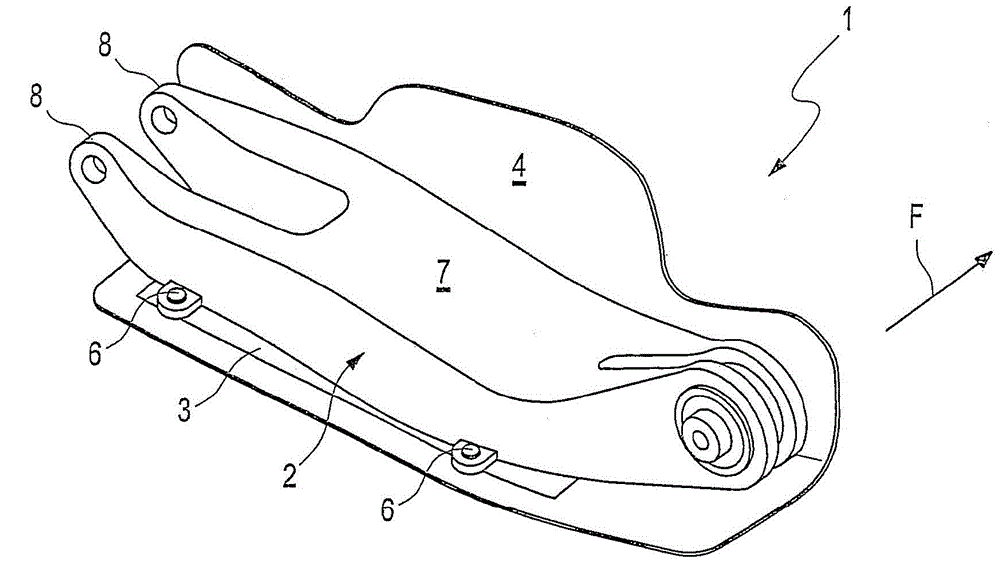

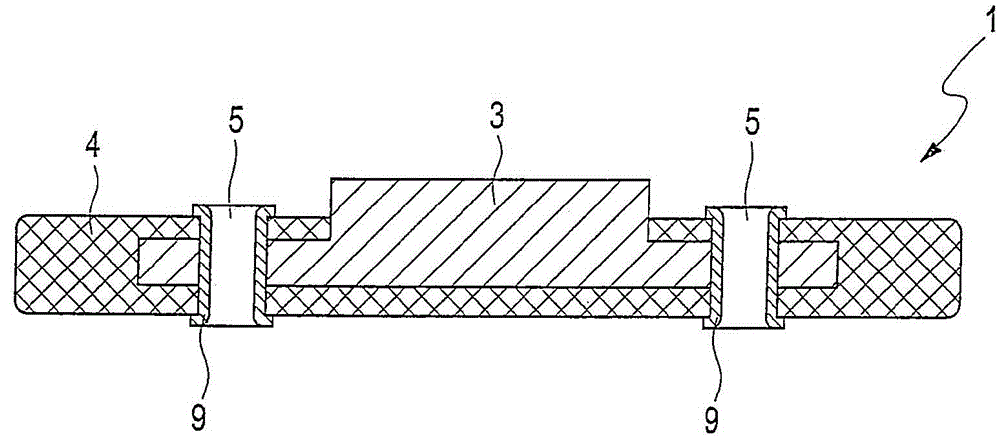

[0043] according to figure 1 , the flow guide device 1 has a reinforcing element 3 and a flow guide element 4 made of plastic connected to it. The stiffening element 3 has a higher rigidity than the flow guiding element 4 . The reinforcing element 3 can be fastened to the chassis control arm 2 by means of fasteners 6 and thereby reinforce the chassis control arm. The air guide element 3 is aerodynamically shaped in such a way that, when the chassis control arm 2 is installed in the wheel suspension of the motor vehicle, it improves the air flow in this area and protects the chassis control arm 2 from damage from stone impacts.

[0044] exist figure 2The chassis control arm 2 is shown in , comprising a base surface 7 and two side plates 8 protruding substantially at right angles from the base surface 7 . The lower end of the side plate 8 is bent relative to the horizontal, so that the fasteners 6 for arranging the reinforcement elements 3 of the air guide device 1 can be ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com