A hydraulic fracturing microseismic monitoring device and monitoring method

A technology of microseismic monitoring and hydraulic fracturing, which is applied in the directions of surveying, earthwork drilling, and mining fluids, etc. It can solve the problems affecting the normal monitoring process of the microseismic monitoring system, the difficulty of installing microseismic monitoring sensors, and the inconvenience of sensor installation position adjustment, etc., to achieve The monitoring effect is good, the microseismic monitoring accuracy is guaranteed, and the use effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

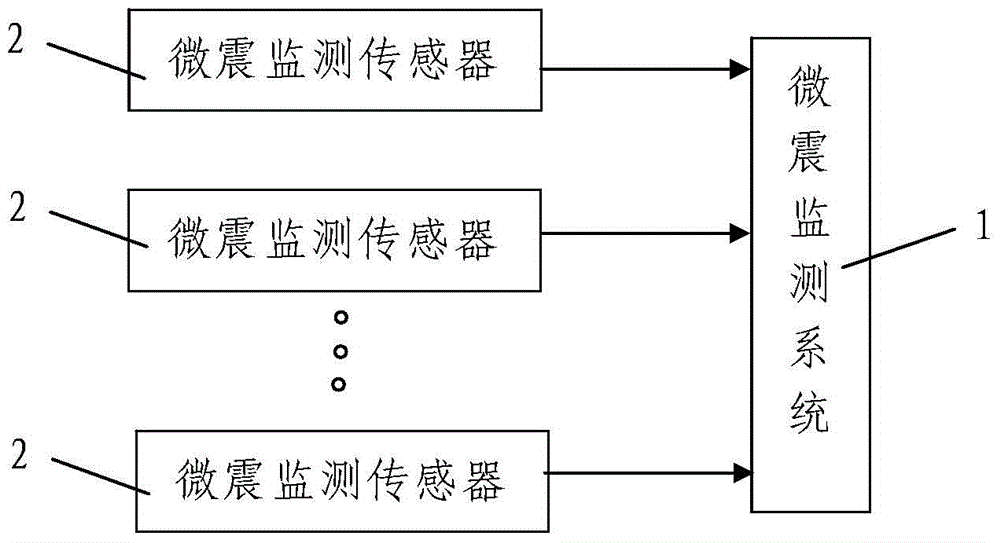

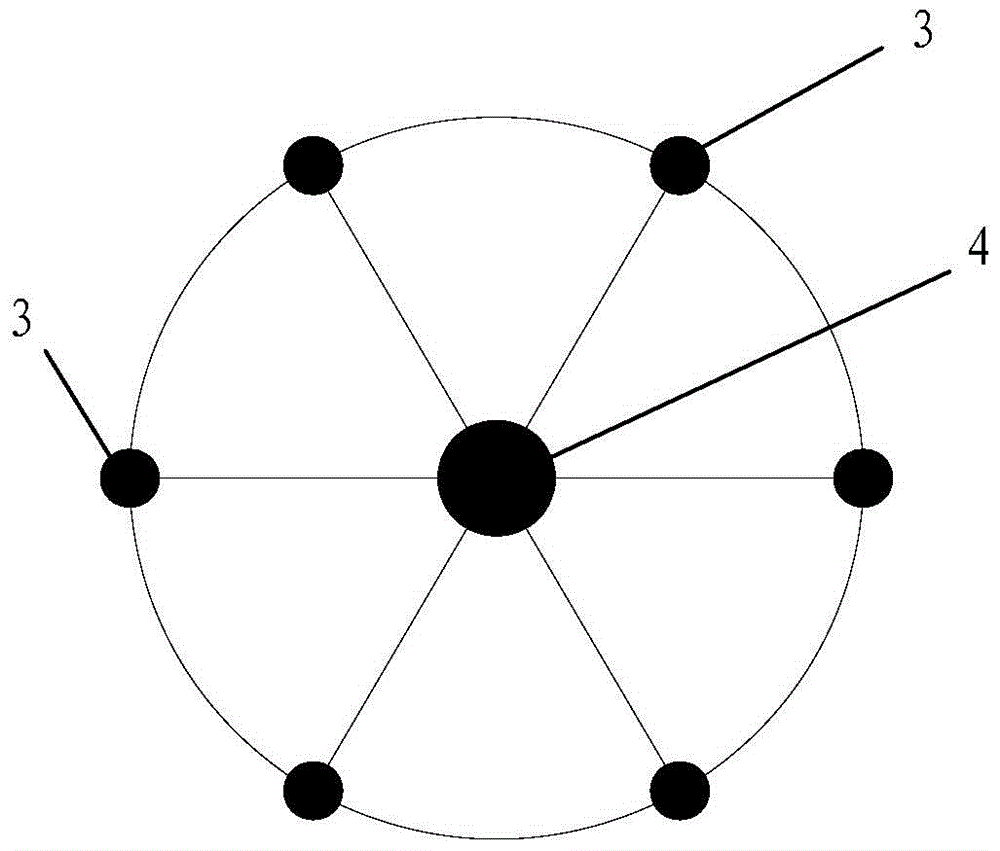

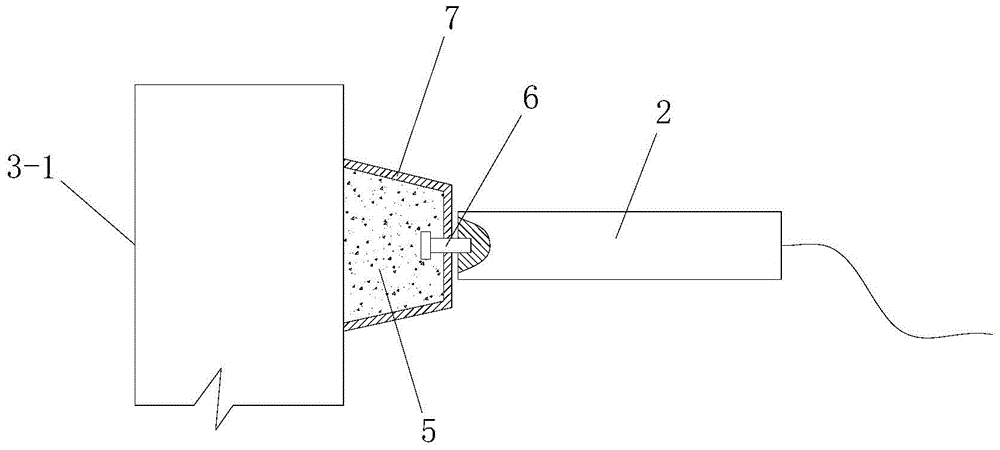

[0047] Such as figure 1 The shown microseismic monitoring device for hydraulic fracturing includes a plurality of microseismic monitoring sensors 2 and a microseismic monitoring system 1 connected to the plurality of microseismic monitoring sensors 2 . A plurality of the microseismic monitoring sensors 2 are respectively arranged on the wellbore installed in the plurality of monitoring wells 3, and the plurality of monitoring wells 3 are arranged on the outside of the fracturing hole for hydraulic fracturing in the current state. The distance between the monitoring well 3 and the fracturing hole is less than 300m. The shafts installed in each of the monitoring wells 3 are composed of a ground exposed section 3-1 above the ground and an underground buried section 3-2 below the ground. The microseismic monitoring sensor 2 is arranged on the outer wall of the ground exposed section 3-1, and the inner end of the microseismic monitoring sensor 2 is equipped with a connecting piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com