Improved vane hydraulic pump and motor

A hydraulic motor and vane type technology, applied in the field of hydraulic machinery, can solve the problems of fluid leakage, inability to further improve the performance and durability of hydraulic machinery, low volumetric efficiency, etc., and achieve the effects of reasonable pressure, simple structure and improved volumetric efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

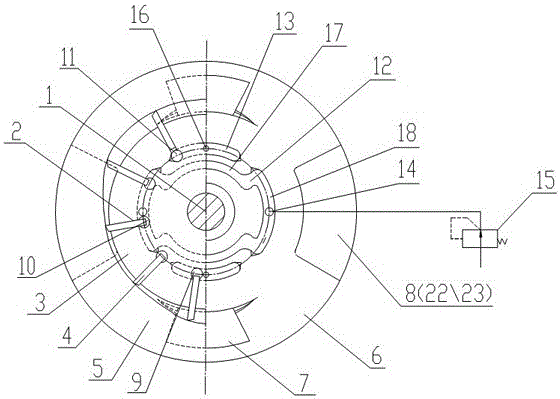

[0026] exist figure 1 In the shown embodiment, the improved vane hydraulic pump and motor include a rotor 3 that rotates on the transmission shaft 1 and is provided with several radial slots 2, vanes 4 that slide along the radial slots 2, and are arranged outside the rotor 3. The stator 5 cooperating with the rotor 3, the side plate 6 installed at both ends of the rotor 3, the side plate 6 is provided with a high-pressure chamber 7 and a low-pressure chamber 8, the corresponding pump is an inflow low-pressure chamber 22, and the corresponding motor is an outflow low-pressure chamber 23 , this embodiment is a hydraulic motor. The top of the blade 4 is in contact with the inner surface of the stator 5, and the control chamber 9 is formed between the blade 4 and the radial groove 2 of the rotor. During the rotation of the rotor 3, the blade 4 slides in and out along the radial groove 2 to form a volume change of the control chamber. At least one volume expansion section control ...

Embodiment 2

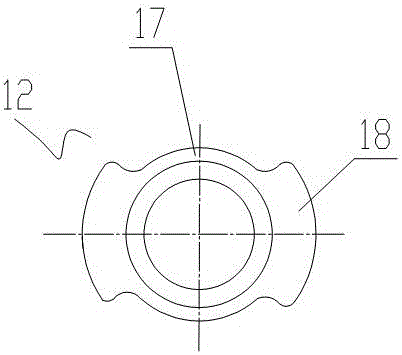

[0028] exist Figure 4 In the illustrated embodiment, the improved vane hydraulic pump and motor are basically the same as in Embodiment 1, except that the leakage recovery chamber 12 includes two groups arranged symmetrically about the same axis, and each group consists of a waist-shaped The groove 18 is connected with two recovery grooves 17 arranged at both ends of the waist-shaped groove 18, and the two groups of leakage recovery chambers 12 are separated.

Embodiment 3

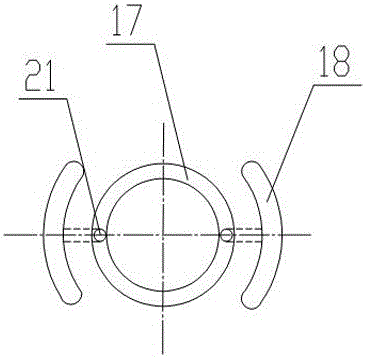

[0030] exist Figure 5 In the shown embodiment, the improved vane hydraulic pump and motor are basically the same as Embodiment 1, the difference is that: the leakage recovery chamber 12 includes two groups arranged symmetrically with the same axis, and each group consists of an arc The recovery tank 17 is connected to a waist-shaped tank 18, and the two groups of leakage recovery chambers 12 are separated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com