Superheated-steam generator device

A technology of superheated steam and nozzles, which is applied in the direction of steam generation, steam generation method, steam superheating, etc., which can solve the problems of difficult welding, large width and depth, and difficulty, and achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

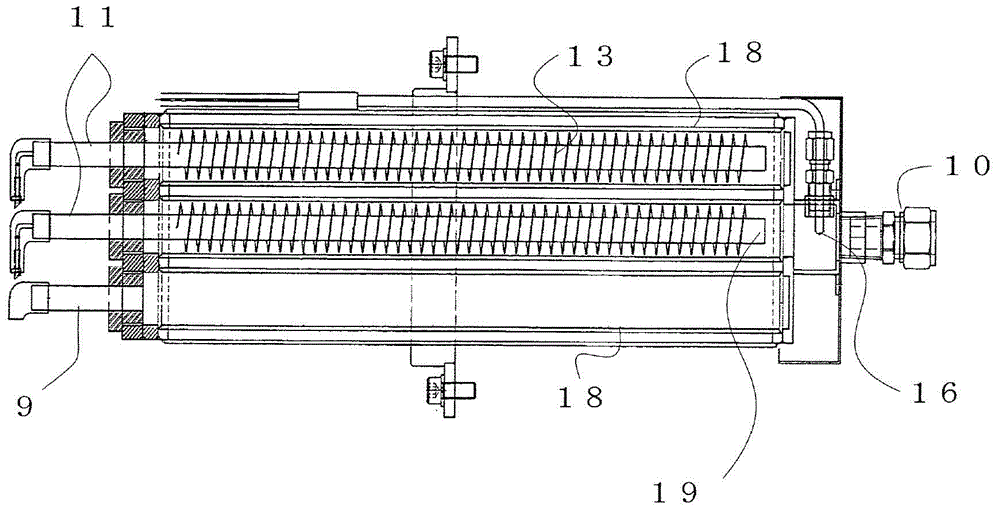

[0020] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0021] [Example]

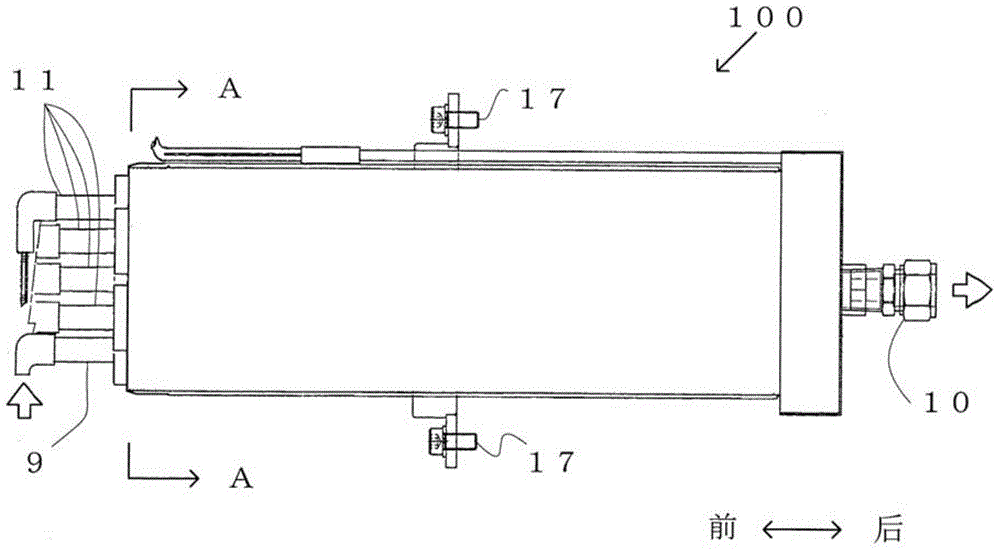

[0022] figure 1 It is a front view of the superheated steam generating nozzle 100 of this invention. The superheated steam generating nozzle 100 is cylindrical and is drawn from figure 1 Steam (steam) is supplied from the steam supply pipe 9 on the left (front) of the furnace, heated by the heater 11, and then discharged into the furnace from the steam discharge pipe 10 on the right (rear). The superheated steam generating nozzle 100 is installed on the furnace wall with mounting screws 17 . The size of the superheated steam generating nozzle 100 is about 50 cm in length and about 11 cm in diameter.

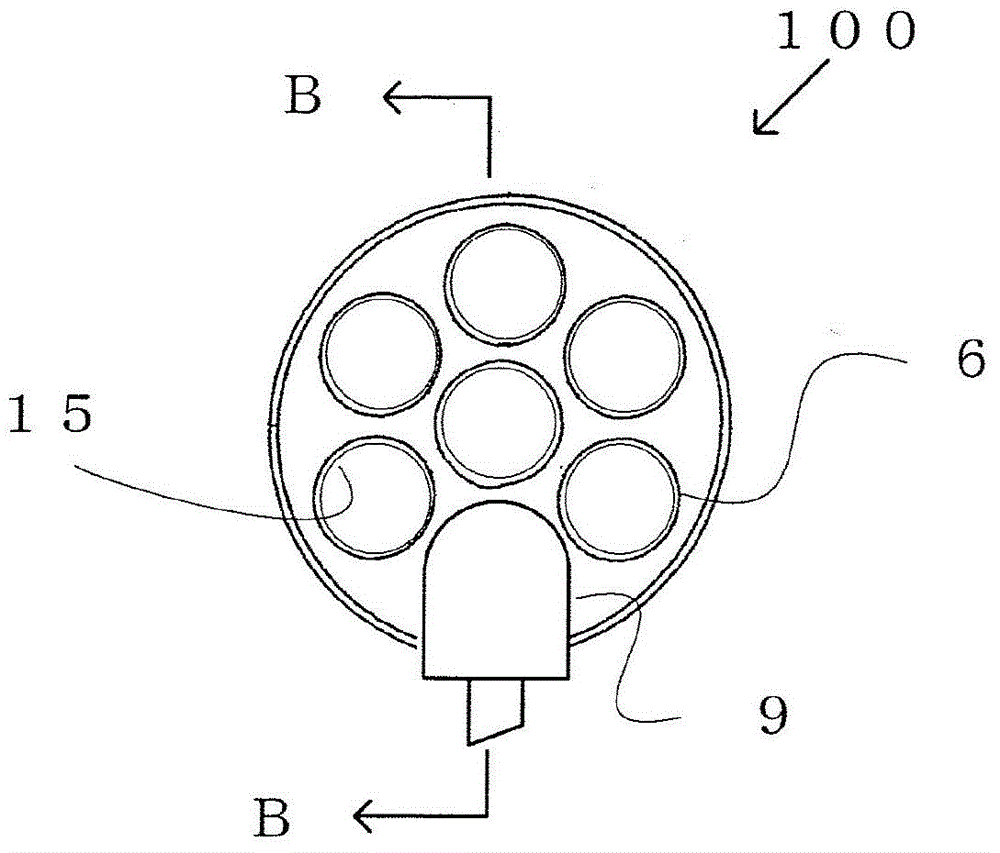

[0023] figure 2 is in figure 1 AA side view of the state after removing the heater 11 in . Seven through-holes 6 are provided on the circular side surface, and internal threads 15 are formed on the inner circumference of the through-hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com