Round tube, tube and fin heat exchanger with streamlined variable-amplitude broken-line corrugated fins

A corrugated fin and broken line technology, which is applied in the field of circular tube-finned heat exchanger fins, can solve the problems of large local flow resistance and poor flow linearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

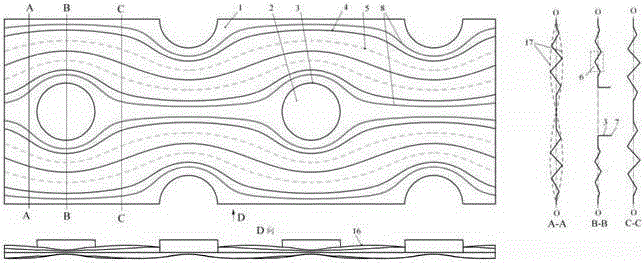

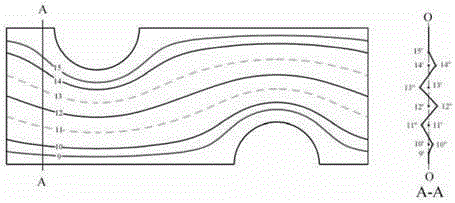

[0020] see figure 1 -2. The present invention includes the circular tube hole 2 on the fin 1 , the ring boss 3 , the stamped streamlined convex corrugation 4 , the concave corrugation 5 and the corrugated shape 6 . The round pipe holes 2 can be arranged in a fork row or in a straight row. The height of the annular boss 3 is equal to the pitch of the fins, which plays the role of positioning the fins. The top of the ring boss 3 is slightly turned outwards with a flanging 7, which is convenient for the fins to pass through the tube and the fins to be positioned. The streamlined convex corrugations 4 (solid lines) and concave corrugations 5 (dotted lines) are alternately distributed between the corrugated region boundaries 8 according to the flow function value of the corrugated region boundaries 8, and are distributed symmetrically about the longitudinal and transverse centerlines of the holes 2 respectively. Both the streamlined convex corrugations 4 and the concave corrugati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com