Dual Beam Delayed Laser Damage Test System

A technology for laser damage and testing systems, used in testing optical properties and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be further described below in conjunction with the examples and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

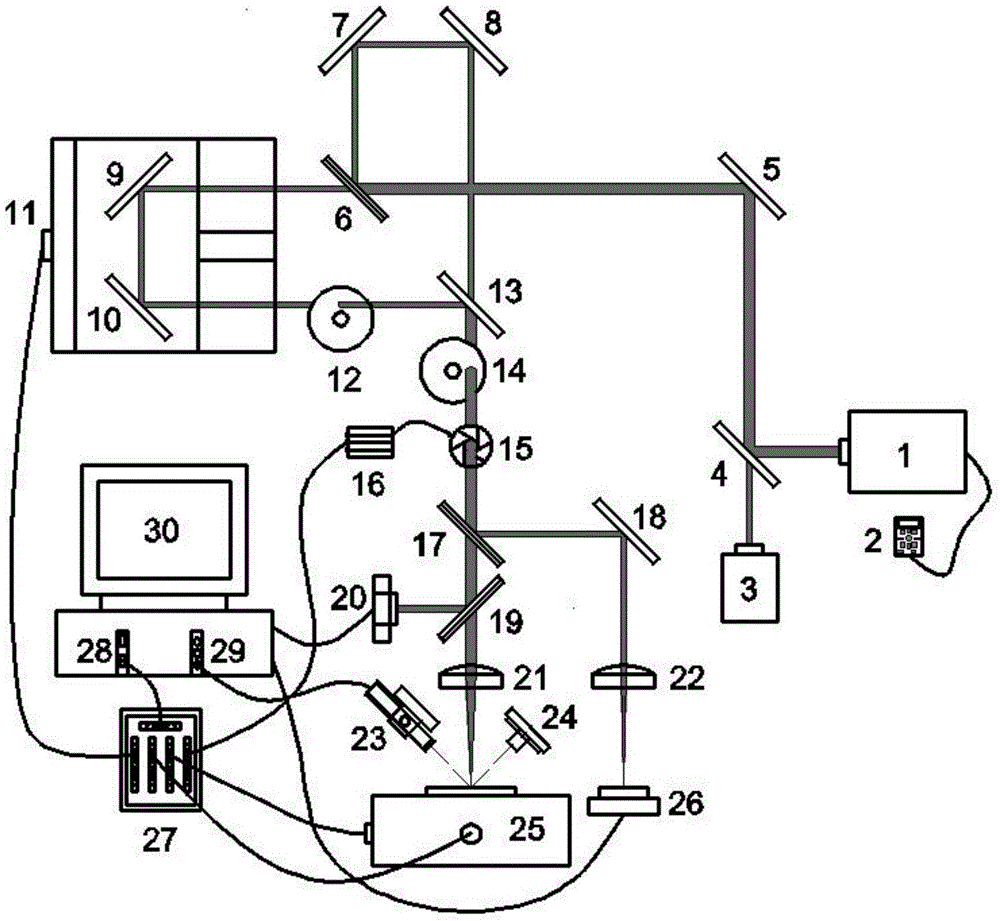

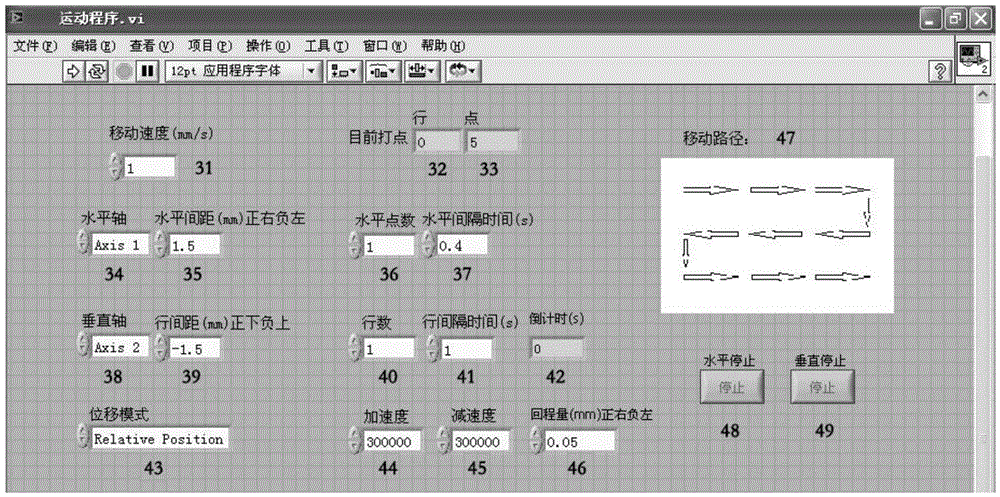

[0020] figure 1 It is a schematic diagram of the double-beam delayed laser damage testing system of the present invention, which is composed of figure 1It can be seen that the dual-beam delayed laser damage testing system of the present invention is applicable to different laser pulse widths and can realize automatic control of the system. In this system, Nd:YAG pulsed laser 1 emits a pulsed laser with a pulse width of 30 ps, a peak energy of 50 mJ, a wavelength of 1064 nm, and a frequency of 10 Hz. Select continuous pulse triggering through laser controller 2, and set the laser energy attenuation to 50%. The pulse laser passes through the first reflector 4 and the second reflector 5 with a center wavelength of 1064nm to the first beam splitter 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com