Acid mist filter for charging lead-acid storage battery

A lead-acid battery and filter technology, applied in lead-acid battery, lead-acid battery construction, dispersed particle filtration, etc., can solve the problems of inability to handle acid mist, pollute the production environment, and simple structure of the rich liquid pot. Compactness, prevention of acid mist overflow, and stable density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

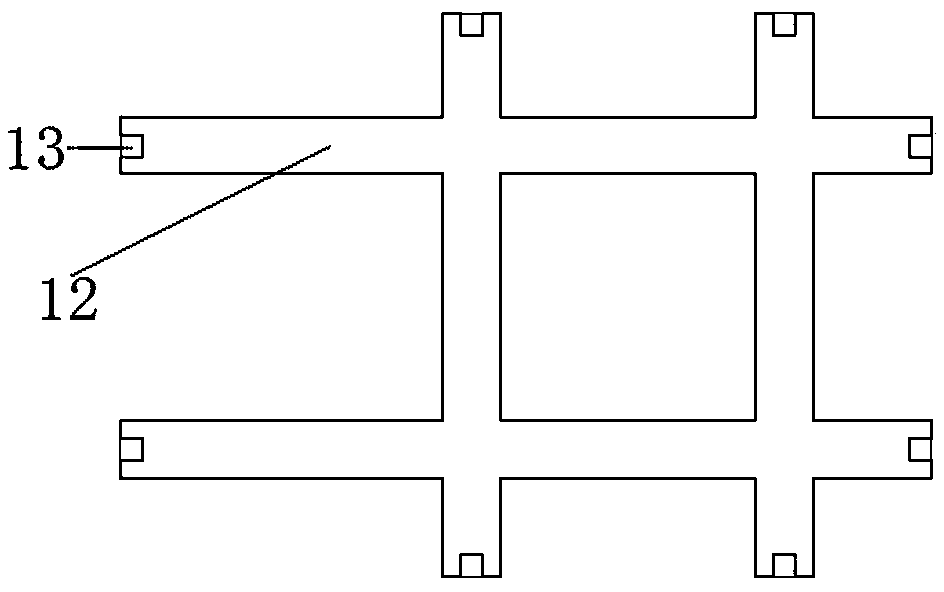

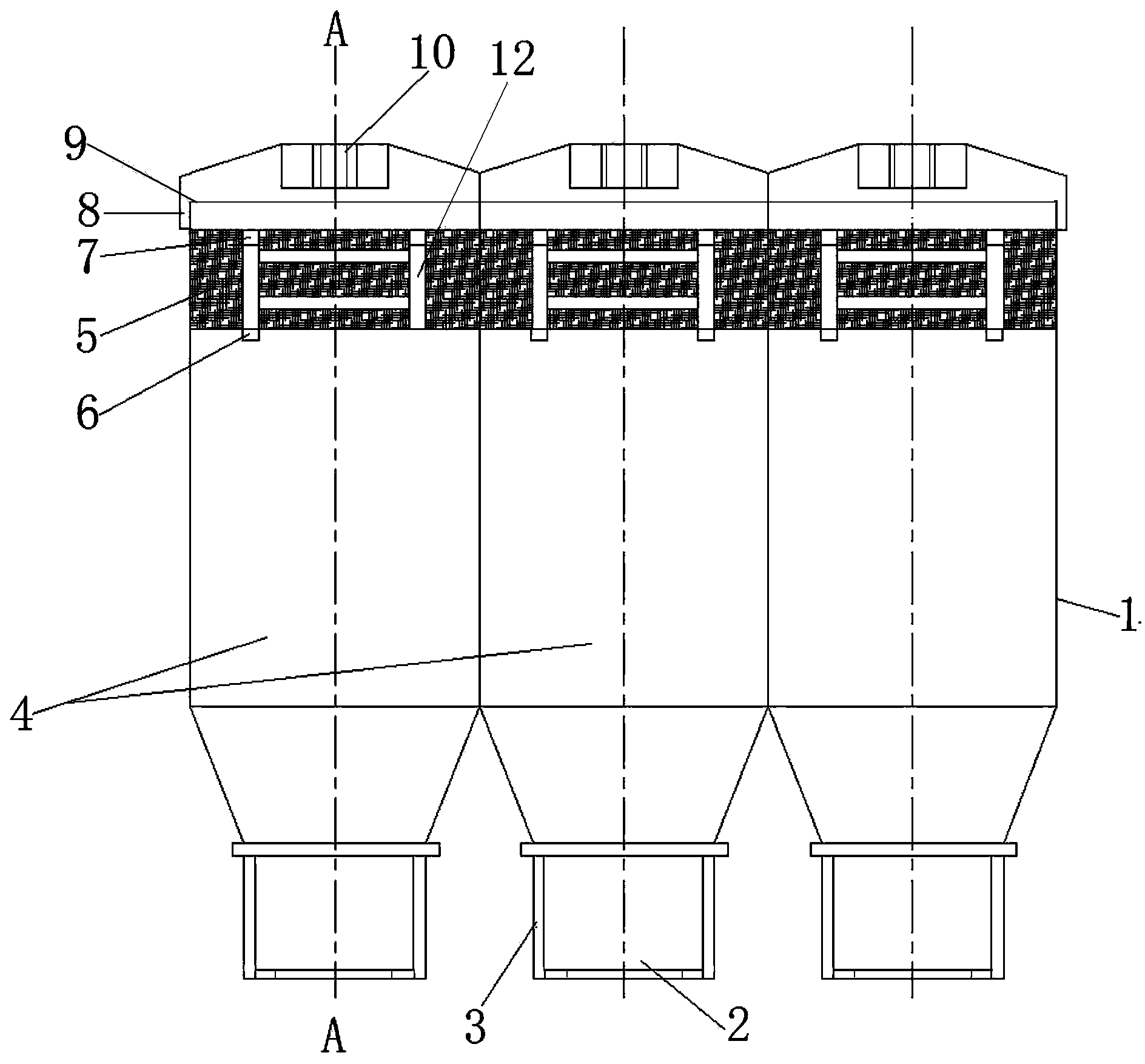

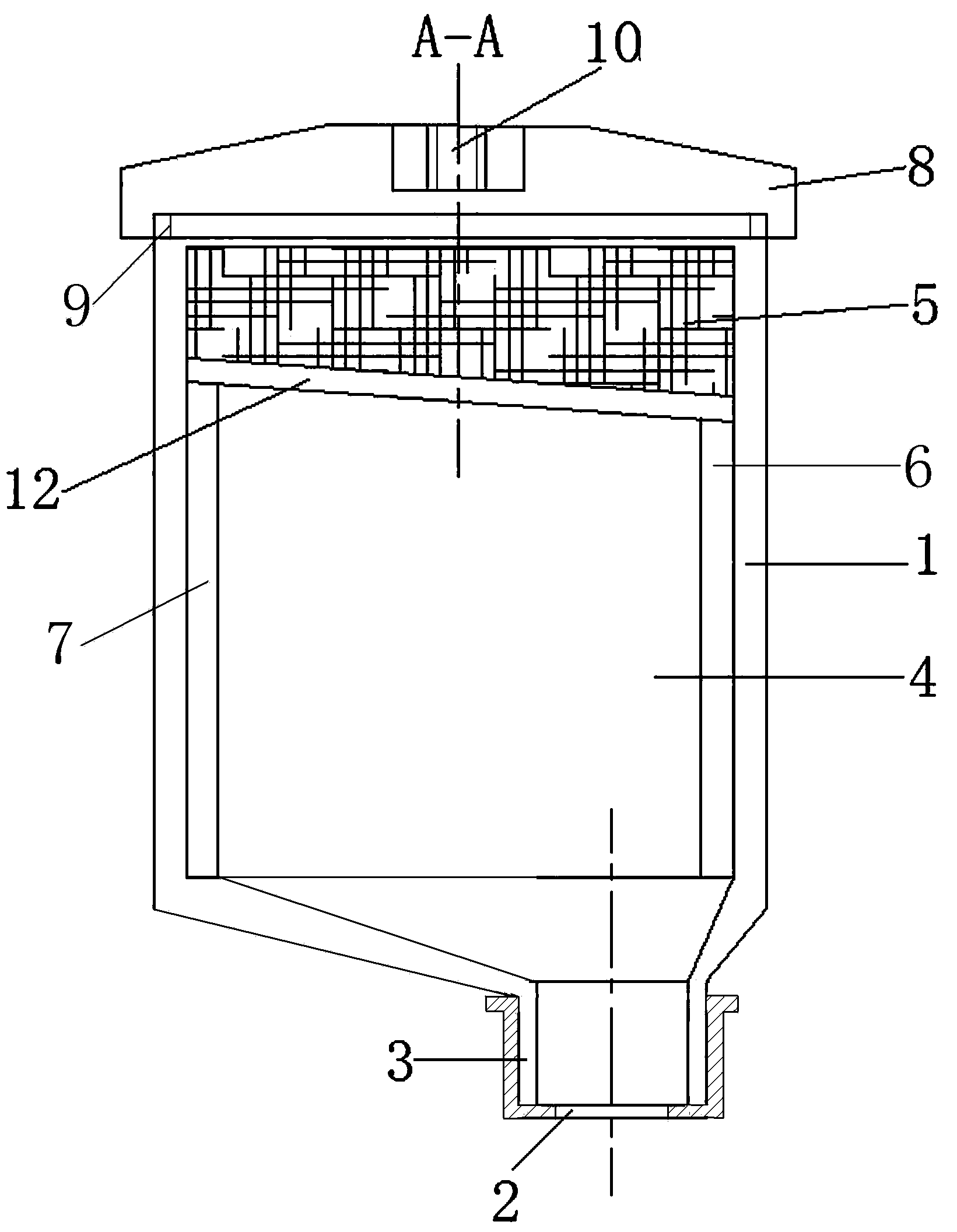

[0017] Refer to attached Figure 1~3 , the acid mist filter for charging the lead-acid battery includes a filter housing 1, an air inlet 2, a sealing sleeve 3, a filter air chamber 4, a filter cotton 5, a filter cotton support 12, a support installation protrusion-6, and a support installation protrusion Lift two 7, the filter upper cover 8 and the exhaust port 10.

[0018] Several evenly distributed filter air chambers 4 are arranged in the filter housing 1, and the lower part of the filter air chamber 4 is provided with an air inlet 2, and a sealing sleeve 3 is installed on the outside of the air inlet 2 for connecting to the liquid injection port of the battery. The bracket installation protrusion 1 6 and the bracket installation protrusion 2 7 are respectively arranged on the front and rear sides of the upper part of the filter air inner wall, and the bracket installation protrusion 1 6 and the bracket installation protrusion 2 7 are set to different heights. The two ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com