Low-permeability rock-fill material concrete panel rock-fill dam

A concrete face, low permeability technology, applied in the direction of dams, barrages, barrages, etc., can solve the problems affecting the stability and safety of the dam body seepage, low permeability coefficient, etc., to ensure the safety of the dam body, improve the seepage stability, Ease of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

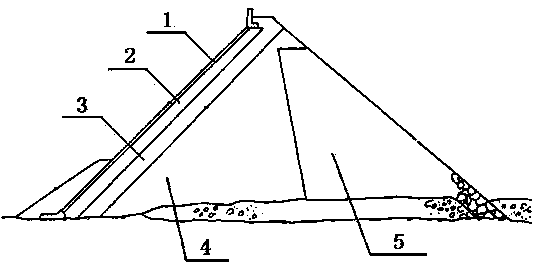

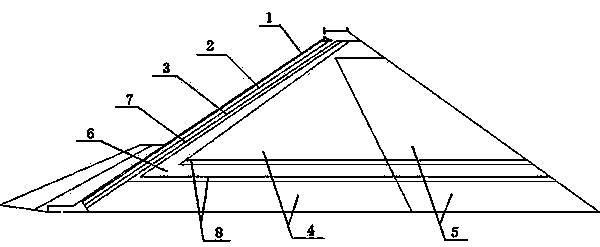

[0018] In order to overcome the problem in the prior art that the permeability coefficient of the rockfill material of the concrete face rockfill dam is low, which affects the stability and safety of the dam body seepage, this embodiment provides a method such as figure 2 The low-permeability rockfill concrete face rockfill dam shown includes concrete face 1, cushion layer area 2, transition area 3, upstream main rockfill area 4 and downstream secondary rockfill area 5, which are arranged in sequence from upstream to downstream. Between the downstream side of the above-mentioned transition zone 3 and the upstream side of the upstream main rockfill area 4, an "L"-shaped drainage area 6 is arranged, and the horizontal part of the drainage area 6 crosses the upstream main rockfill area 4 and the downstream The bottom of the secondary rockfill area 5, and horizontally divides the upstream main rockfill area 4 and the downstream secondary rockfill area 5 into upper and lower parts,...

Embodiment 2

[0021] On the basis of Example 1, according to the engineering practice, the slope ratios of the concrete panel 1, the cushion area 2, the transition area 3, and the filter area-7 are the same, all of which are 1:m, and the value range of m is 1.3 to 1.6; the partition slope between the vertical part of the drainage area 6 and the upstream main rockfill area 4 is 1: s, and the value range of s is 1.4 to 1.7; the horizontal part of the drainage area 6 Set between the highest water level and the lowest water level in the downstream; the partition slope of the upstream main rockfill area 4 and the downstream secondary rockfill area 5 is 1:t, and the value range of t is 0 to 1.35, which is determined according to the actual project. Generally take 0.2; the selection of the above parameters must meet the requirements of the "Code for Design of Concrete Face Rockfill Dams" (DL / T5016-2011, SL228-98).

[0022] The concrete face 1 of this embodiment is used as an anti-seepage structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com