Sand mold reinforcing liquid as well as preparation and use methods thereof

A technology of reinforcing liquid and sand molds, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of easy damage, low surface strength of sand molds, and easy moisture absorption, so as to save consumption, improve the roughness of castings, Blocks the effect of deep penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

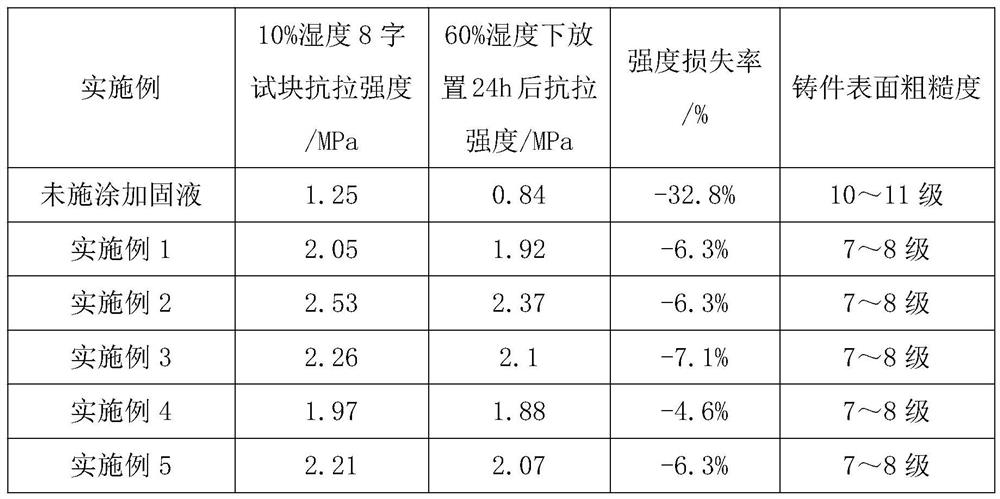

Examples

preparation example Construction

[0031] A method for preparing a sand mold reinforcement liquid, comprising the steps of:

[0032] (1) Open the liquid dispersing tank and stir, add organic solvent, add surfactant, anti-skinning agent and anti-sedimentation agent at 800r / min dispersing speed, and disperse for 20 minutes;

[0033] (2) Slowly add the binder, disperse at 800r / min for 20 minutes after the feeding, and the preparation is completed.

Embodiment 1

[0035] A sand mold strengthening solution comprises, in parts by mass, 100 parts of ethanol, 20 parts of phenolic resin, 5 parts of organic bentonite, 0.05 part of tert-butylphenol and 1 part of fatty alcohol polyoxyethylene ether.

[0036] A method for preparing a sand mold reinforcement liquid, comprising the steps of:

[0037] (1) Open the liquid dispersion tank and stir, add 100 parts of ethanol, add 5 parts of organic bentonite, 0.05 parts of tert-butylphenol and 1 part of fatty alcohol polyoxyethylene ether at a dispersing speed of 800r / min, and disperse for 20 minutes;

[0038] (2) Slowly add 20 parts of phenolic resin, disperse at 800r / min for 20 minutes after the addition, and the preparation is completed.

Embodiment 2

[0040] A sand mold strengthening liquid, comprising 100 parts by mass of butyl acetate, 15 parts of epoxy resin, 5 parts of hydrogenated castor oil wax, 0.05 part of methoxyphenol and 0.5 part of alkylphenol polyoxyethylene ether.

[0041] A method for preparing a sand mold reinforcement liquid, comprising the steps of:

[0042] (1) Open the liquid dispersing tank and stir, add 100 parts of butyl acetate, add 5 parts of hydrogenated castor oil wax, 0.05 part of methoxyphenol and 0.5 part of alkylphenol polyoxyethylene ether at a dispersing speed of 800r / min, and disperse for 20 minute;

[0043] (2) Slowly add 15 parts of epoxy resin, disperse at 800r / min for 20 minutes after feeding, and the preparation is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com