Rotatable extension-type node and operation method thereof

A node and operating hole technology, applied in the field of retractable nodes with rotation, can solve the problems of structural manufacturing trouble, increase bearing capacity, low flexibility, etc., and achieve the effects of low construction cost, increased service life, and improved operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

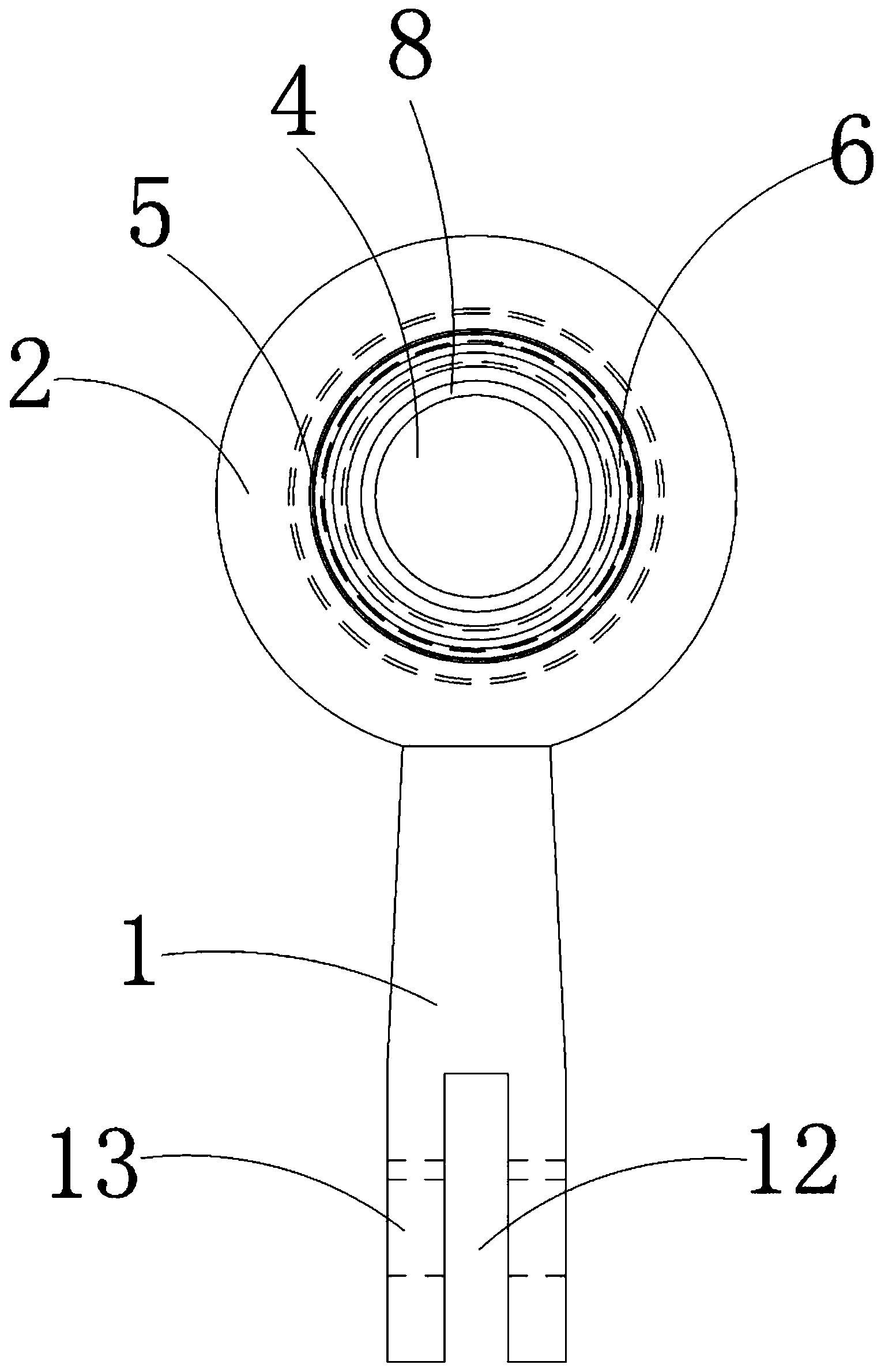

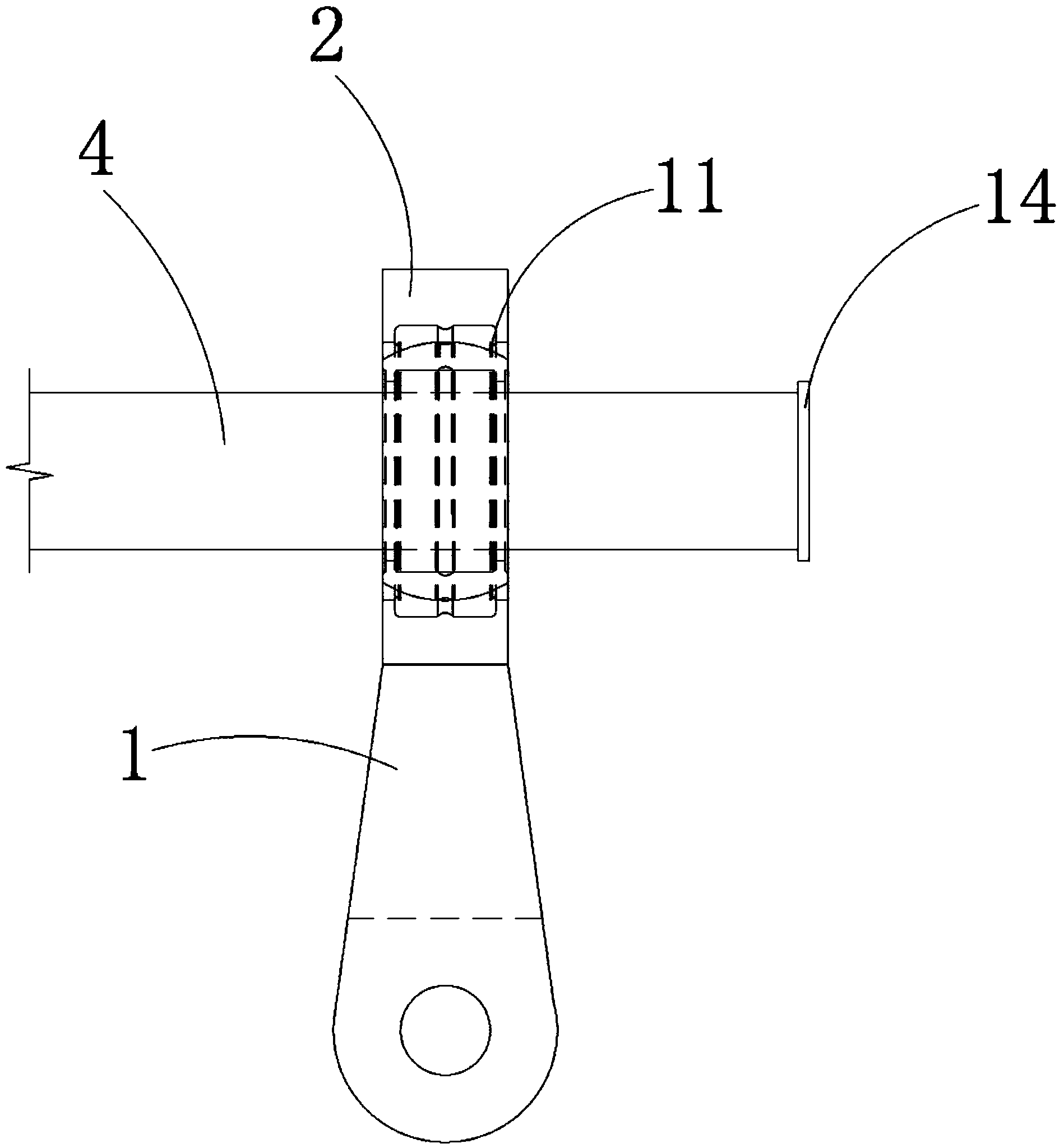

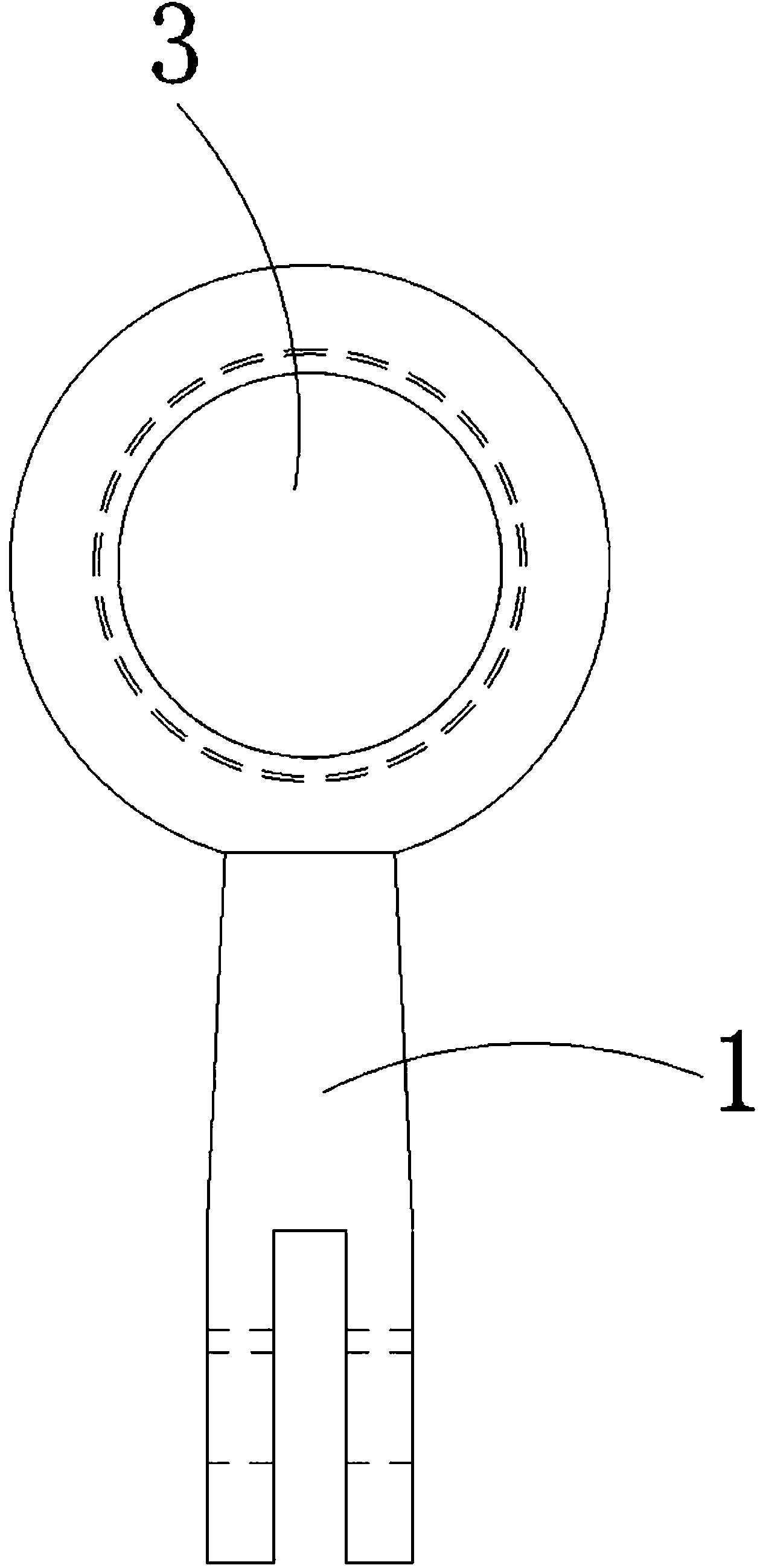

[0035] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a telescopic node with rotation includes a fixed base 1 and an operating base 2, the upper part of the fixed base 1 is provided with an operating base 2 fastened to the fixed base 1, The operation base 2 is provided with an operation hole 3, the operation hole 3 is provided with a sliding shaft 4, and the inner wall of the operation hole 3 is provided with a bearing outer ring 5, and the bearing outer ring 5 and A bearing inner ring 6 is provided between the sliding shafts 4, and the inner wall of the bearing inner ring 6 is provided with a concave embedded base groove 7, and the embedded base groove 7 is provided with a UHMWPE board8.

[0036] The outer wall of the bearing outer ring 5 is provided with a concave lubricating groove 9, the inner wall of the bearing outer ring 5 is a spherical surface, and the outer wall of the bearing inner ring 6 is closely attached to the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com