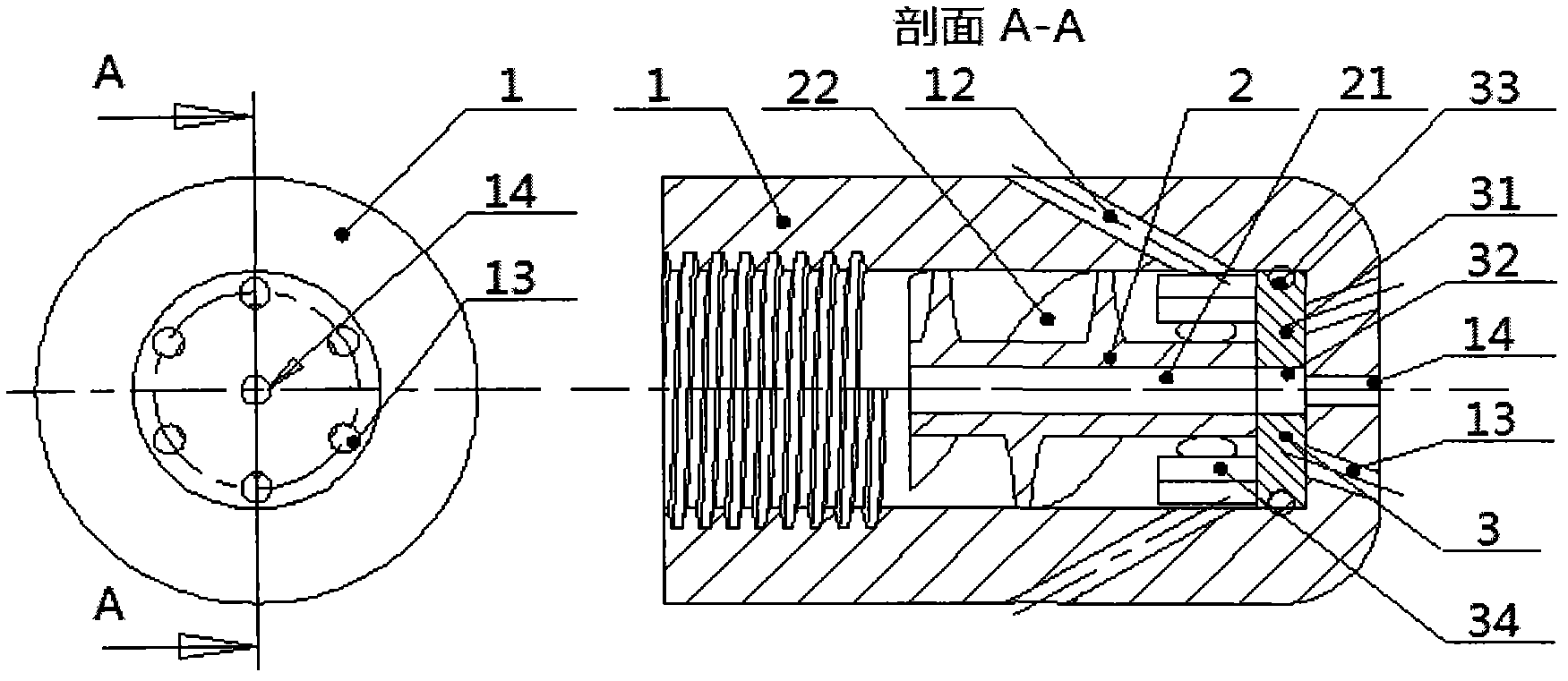

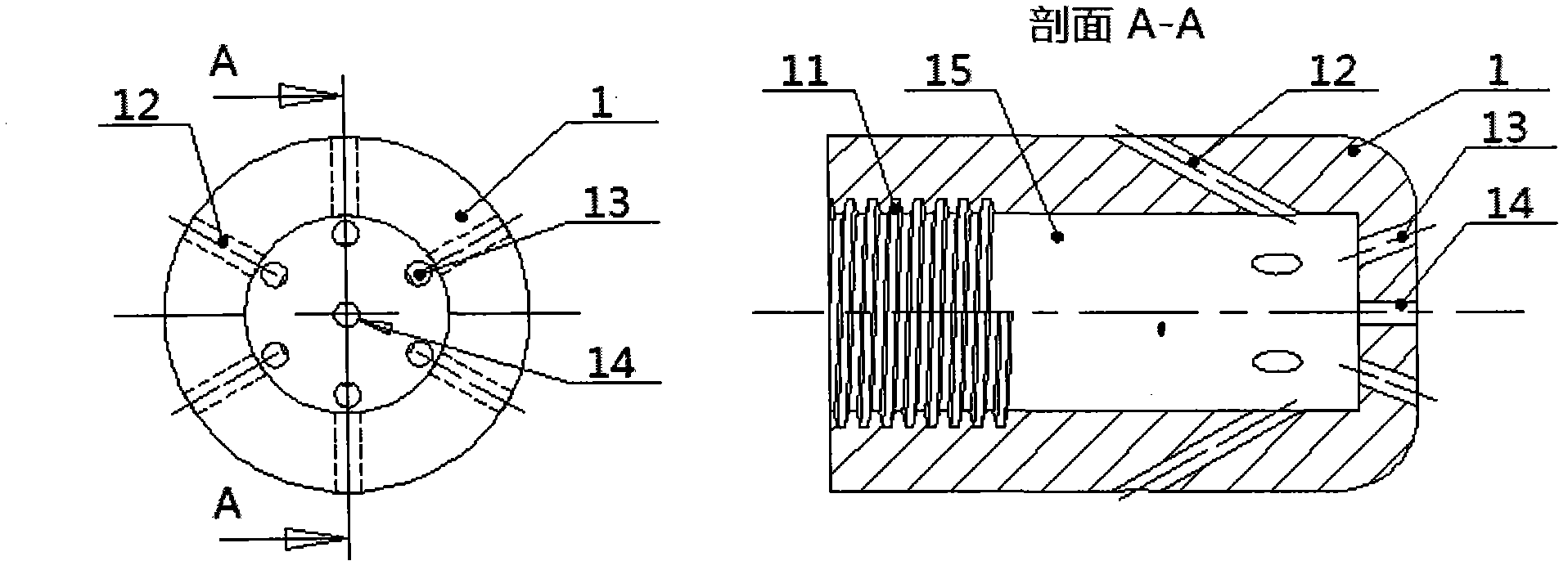

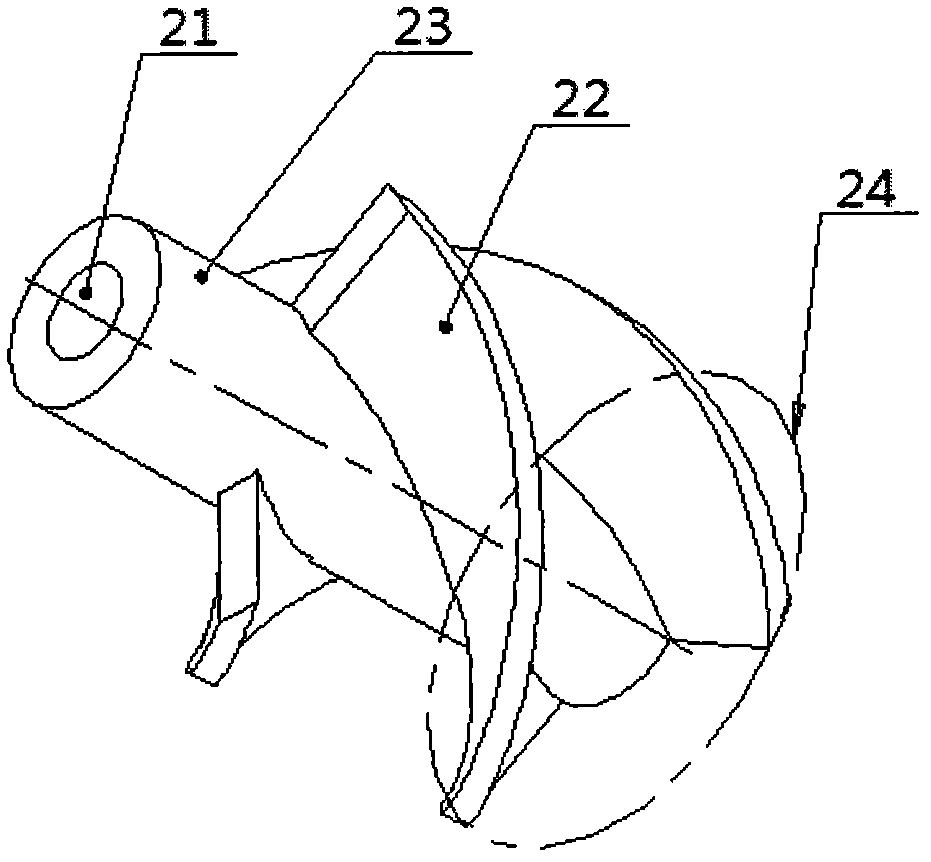

Multi-orifice nozzle device with rock breaking and self-propelling modes

A multi-hole nozzle and dual-mode technology, applied in construction and other directions, can solve problems such as insufficient hydraulic energy, and achieve the effects of reducing frictional resistance, increasing extension limit, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]A rock-breaking and self-advancing dual-mode porous nozzle device of the present invention mainly includes: a nozzle body, an impeller shaft, a switch and the like. It is characterized in that a switch driven by the impeller shaft is added to the nozzle body that requires the phase of the forward hole and the backward hole. Since the phases of the other forward holes and the rear hole are consistent except for the forward center hole, the switch The hollow part of the front face of the device (or the shielding wall of the front face) is in phase with the shielding wall (or hollow part) of the side respectively, so the forward eyelet and the rearward eyelet around the center cannot be fully opened at the same time, when the high-speed fluid flows through the impeller shaft, Rotate the shaft of the driving impeller, so that the forward holes and the backward holes are opened alternately, so that the jet rock breaking and the nozzle self-progress alternately, and the forward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com