Electric connector for circuit board and electric connector assembly

A circuit substrate and electrical connector technology, which is applied in the direction of two-component connection devices, parts of connection devices, circuits, etc., can solve the problems of limited board thickness and inability to realize connector locking, etc., and achieve the effect of reliable locking state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

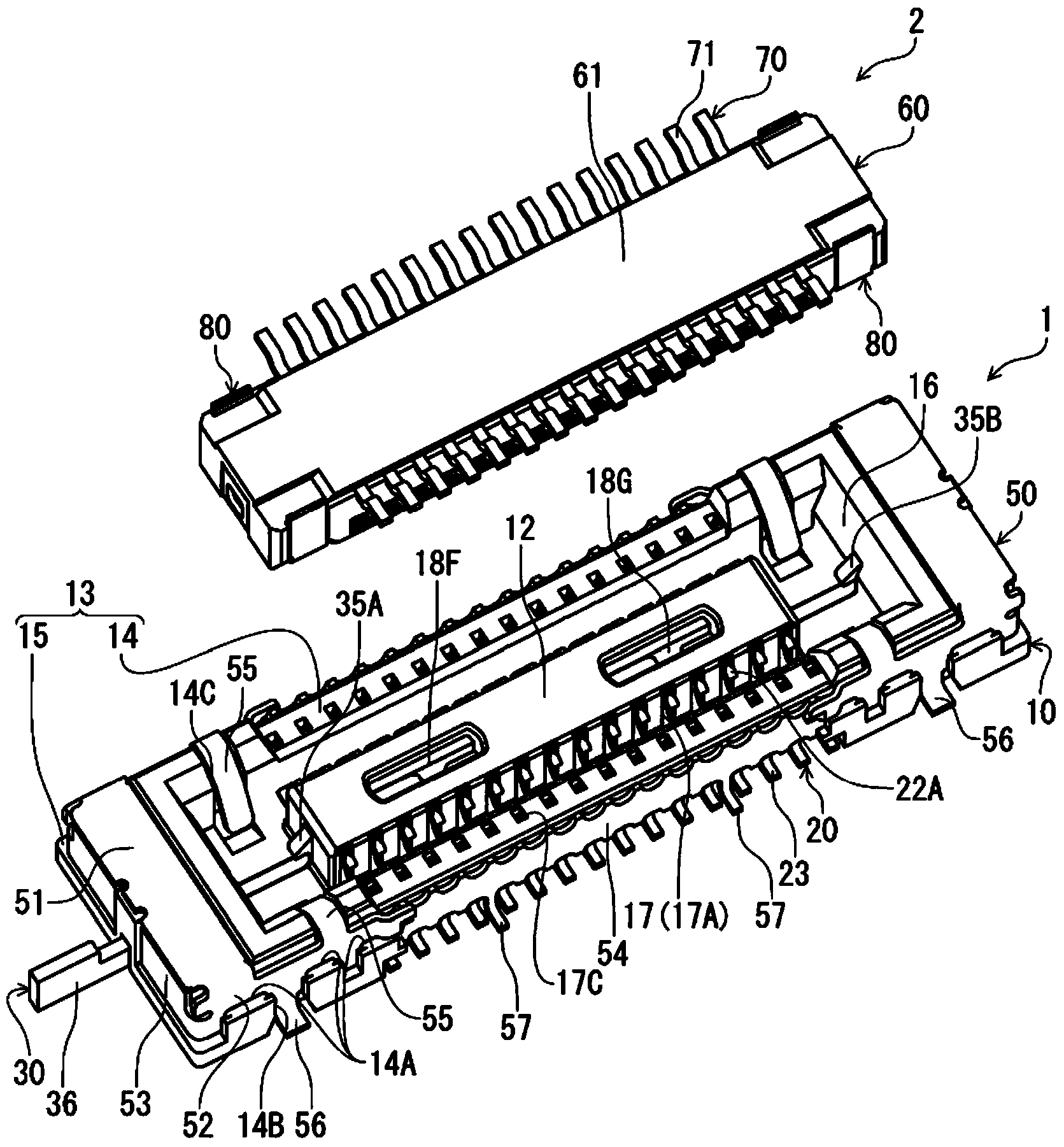

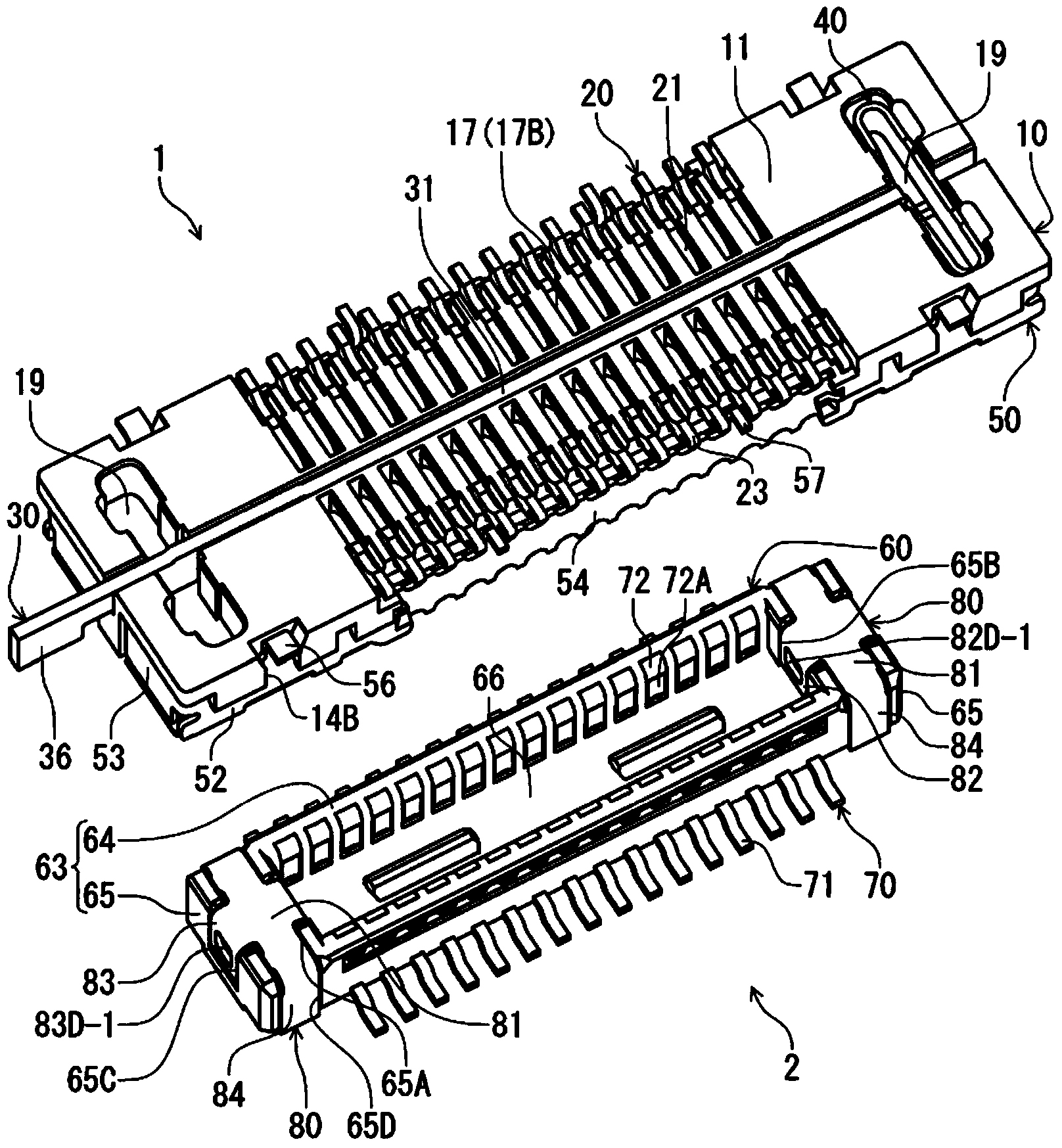

[0041] figure 1 It is a perspective view of the receptacle connector 1 according to this embodiment and the plug connector 2 fitted to the receptacle connector 1 from above, showing a state before the connectors are fitted. figure 2 will be figure 1 The perspective view in which the receptacle connector 1 and the plug connector 2 are shown upside down is shown in a posture in which the plug connector 2 is fitted from below.

[0042] The receptacle connector 1 and the mating connector plug connector 2 of the receptacle connector 1 in this embodiment are electrical connectors for circuit boards respectively arranged on the mounting surfaces of different circuit boards (not shown), and constitute in a direction at right angles to the face of each circuit board ( figure 1 The up and down direction) is the connector assembly in the plugging and unplugging direction.

[0043] Such as figure 1 As shown, the receptacle connector 1 has: a receptacle-side housing 10, the receptacle...

no. 2 approach >

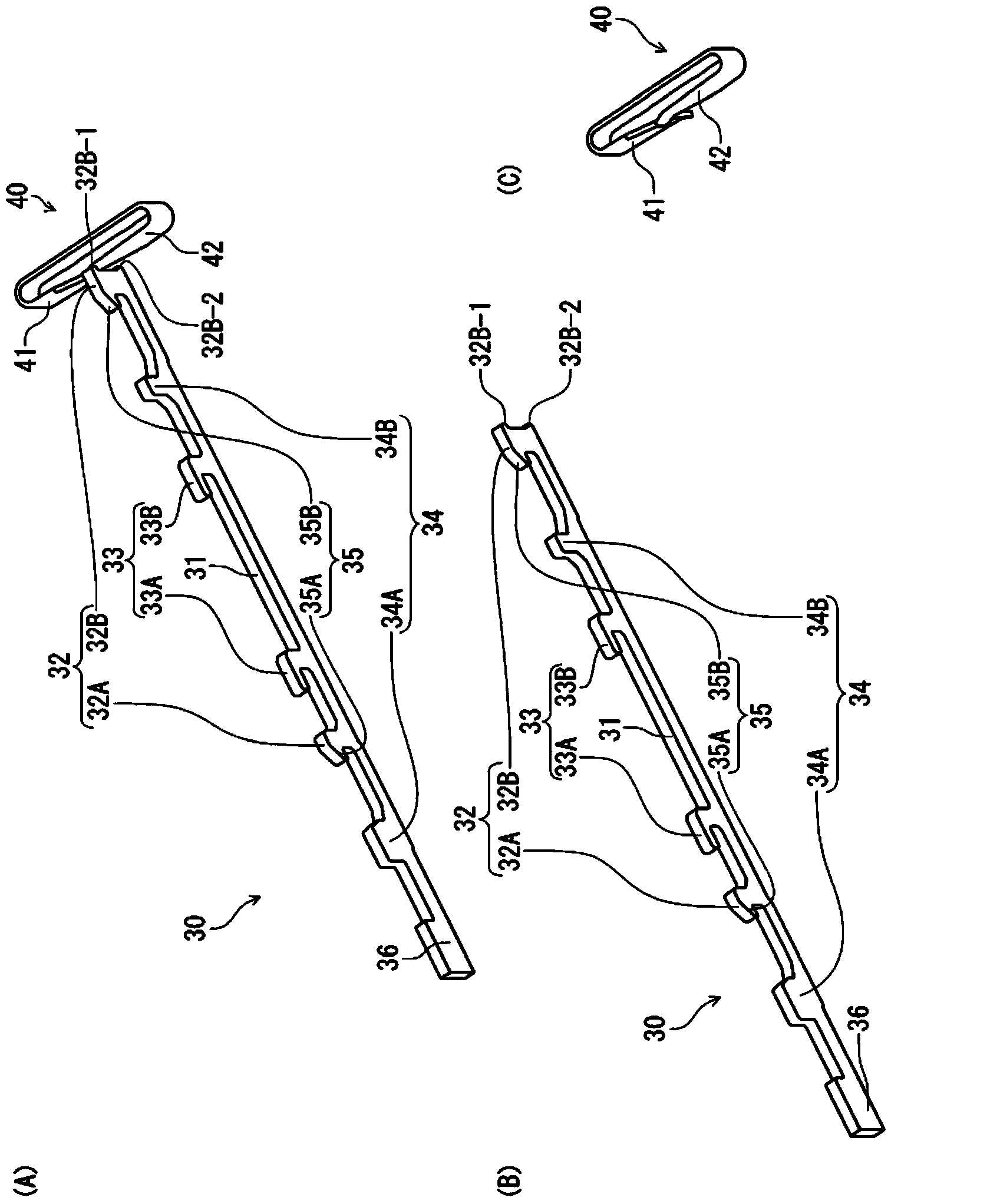

[0102] In the first embodiment, the socket connector 1 is provided with the locking metal piece 30 and the elastic deformation member 40, and the elastic deformation member 40 applies force to the locking metal piece 30. However, in this embodiment, no elastic deformation member is provided. It is different from the first embodiment in that the locking metal fitting itself has an elastically deformable portion capable of elastically deforming in the direction in which the terminals are arranged.

[0103] Figure 9 (A) is a perspective view showing the lock metal fitting 130 according to this embodiment. The locking metal fitting 130 of the present embodiment is produced by punching a metal plate into a predetermined shape, and then bending the metal plate in the thickness direction. Such as Figure 9 As shown in (A), the locking metal fitting 130 is formed so that two locking metal fittings 30 in the first embodiment are overlapped, and the side edges of their second rising ...

no. 3 approach >

[0108] In the first embodiment, the elastically deformable member 40 is formed by bending a strip-shaped metal plate member, but in this embodiment, the elastically deformable member is not made of such a metal plate member but is made of a coil spring. , which is different from the first embodiment. Figure 10 (A) is a cross-sectional view showing part of the receptacle connector 201 according to this embodiment. In this embodiment, the description will focus on the differences from the first embodiment, and for the parts corresponding to the receptacle connector 1 in the first embodiment, "200" will be added to the reference numerals in the first embodiment. ” and its description is omitted.

[0109] Figure 10 (A) shows one end side portion of the receptacle connector 201 according to this embodiment (with Figure 5 The part corresponding to the left half of (B). Such as Figure 10 As shown in (A), the receptacle connector 201 has an elastically deformable member 240 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com