Plate and strip surface horizontal inspection device

An inspection device, a horizontal technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of expensive, unsuitable for low-speed production lines, etc., achieve light structure, easy implementation, and prevent overhanging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

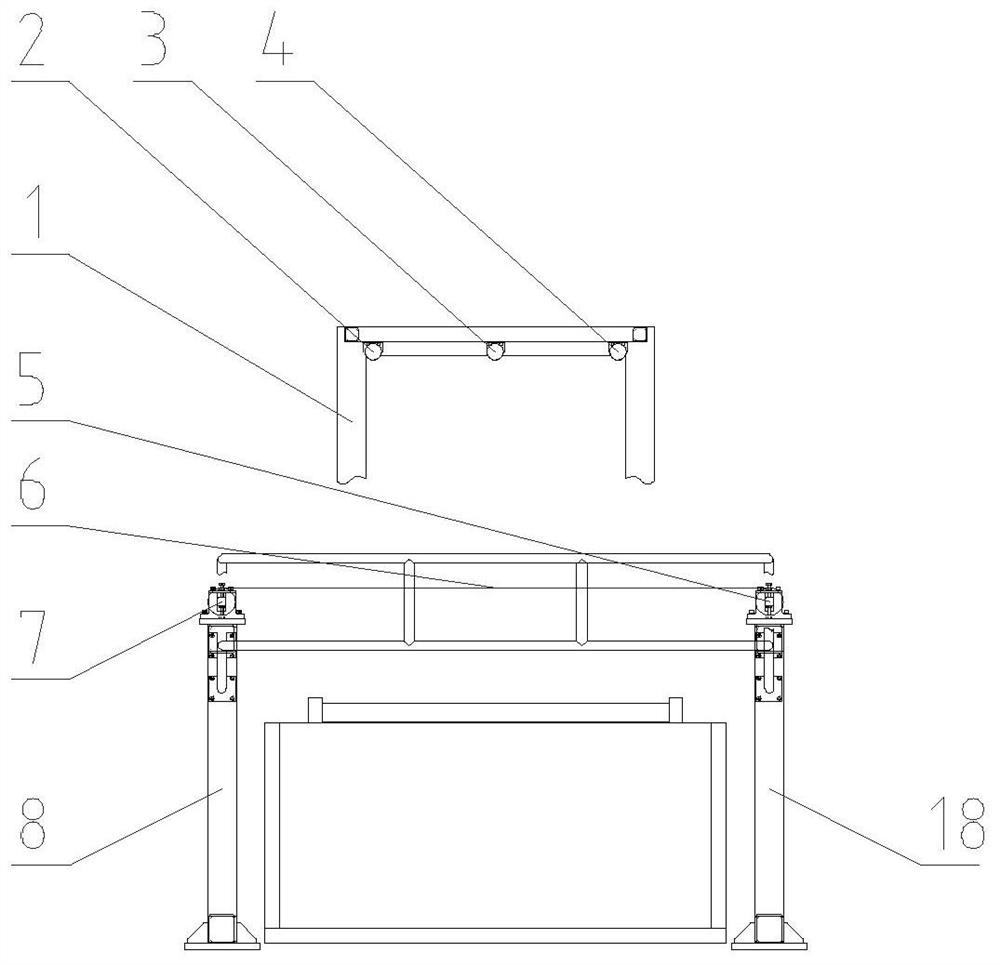

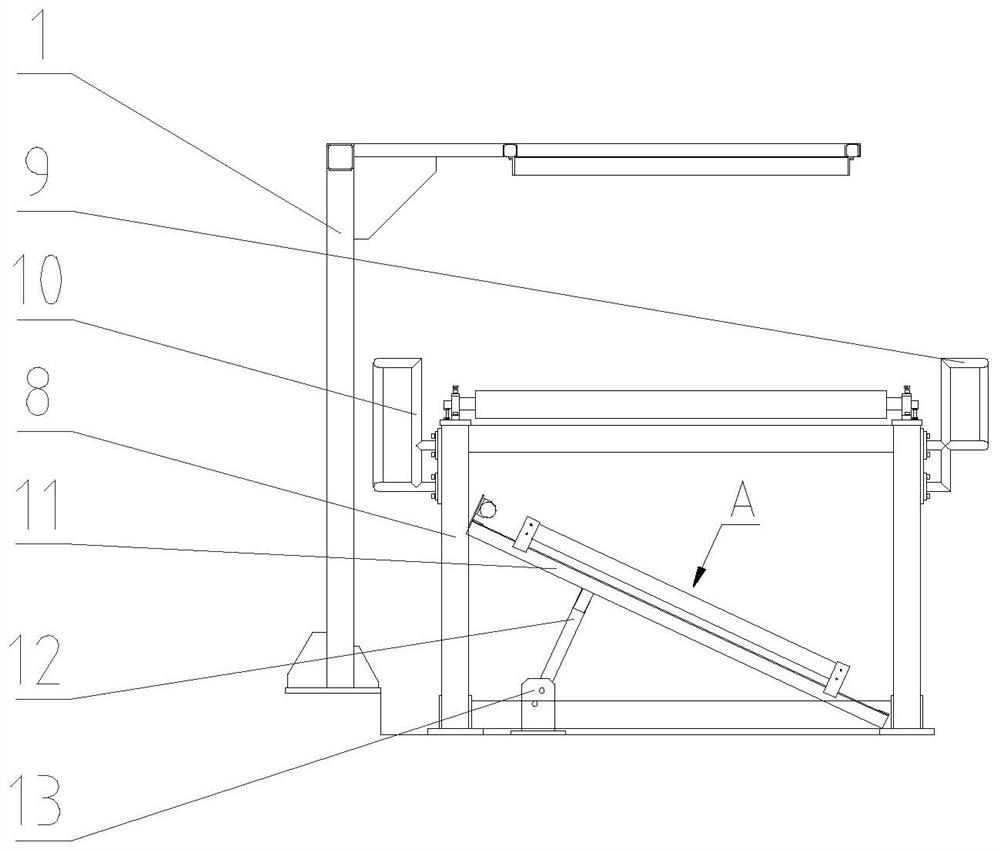

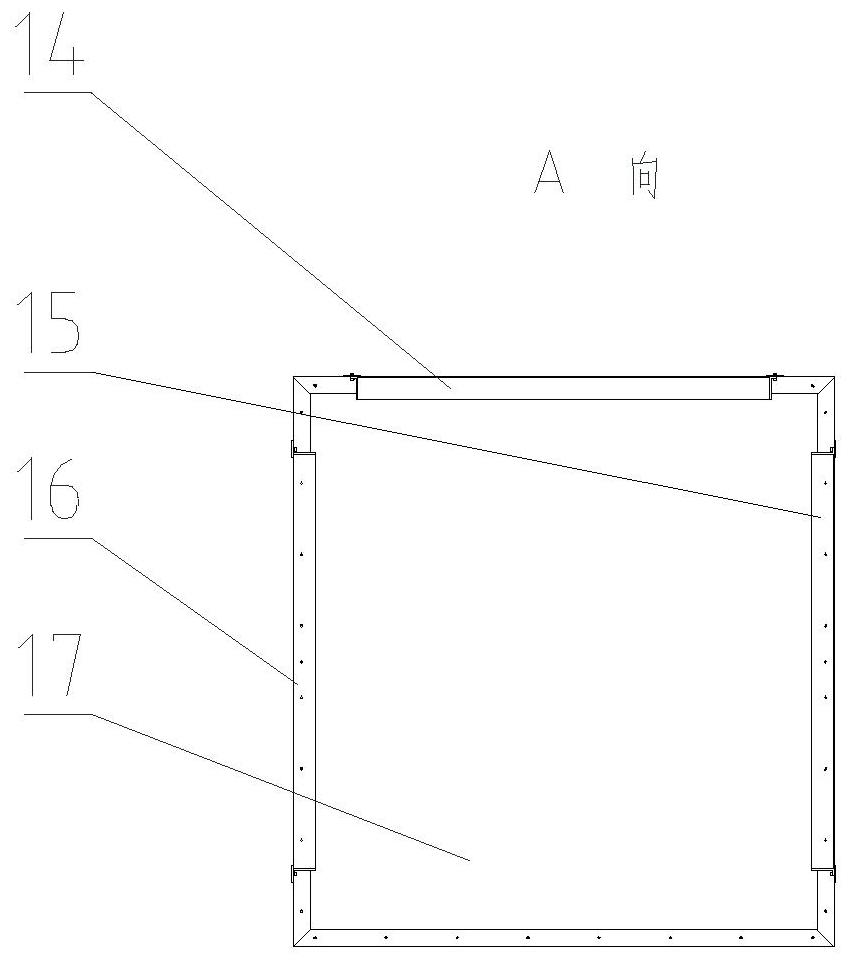

[0028] refer to Figure 1 ~ Figure 3 A strip surface horizontal inspection device shown includes a front inspection mechanism, a back inspection mechanism, an entrance idler 5, an exit idler 7, and an idler bracket; the front inspection mechanism is arranged on one side of the idler bracket; The back inspection mechanism is arranged in the idler bracket and its height is smaller than the idler bracket; the entrance idler 5 and the exit idler 7 are arranged in parallel and the upper surfaces of the two are at the same level, and the entrance idler 5 and the exit idler 7 are movably connected to the inlet side and the outlet side of the idler bracket respectively.

[0029] In the specific application, first place the strip 6 on the entrance idler 5 and the exit idler 7, and adjust the elevation of the entrance idler 5 and the exit idler 7 up and down based on the operating line of the unit, so that the entrance idler 5 It is at the same level as the upper surface of the exit id...

Embodiment 2

[0035] refer to figure 1 with figure 2 In the shown horizontal inspection device for the strip surface, on the basis of the first embodiment, the idler support includes a left support 8 and a right support 18 arranged in parallel; the left support 8 is connected with an exit idler 7. The entrance idler 5 is connected to the right support 18, and the exit idler 7 is parallel to the entrance idler 5; the back inspection mechanism is placed between the left support 8 and the right support 18.

[0036] In actual use, the idler bracket adopts this technical solution, which not only facilitates its supporting effect on the strip 6, but also facilitates the layout of the inspection mechanism on the back side.

Embodiment 3

[0038] refer to figure 2 A strip surface horizontal inspection device shown, on the basis of Embodiment 1 or Embodiment 2, also includes an operating side fence 9 and a transmission side fence 10 arranged in parallel; the operation side fence 9 and the transmission side fence 10 The two ends of the fence 10 are respectively fixedly connected to the top of the left bracket 8 and the right bracket 18 of the idler bracket, and the operation side fence 9 and the transmission side fence 10 are perpendicular to the entrance idler 5 and the exit idler 7 respectively.

[0039] In actual use, the connection of the left bracket 8 and the right bracket 18 can be realized by operating the side fence 9 and the transmission side fence 10, which can enhance its stability, and can also realize the safety protection effect on the observer when observing the surface quality of the strip 6 .

[0040] In specific application, the operation side fence 9 and the transmission side fence 10 can ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com