Interconnect structure and method of forming the same

A technology of interconnect structure and dielectric layer, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problem of decreased quality and reliability of interconnect structures, increased etching rate, and conductive plug overhang, etc. The problem is to prevent the undercut phenomenon between the interfaces, improve the quality and reliability, and eliminate the existence of the interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

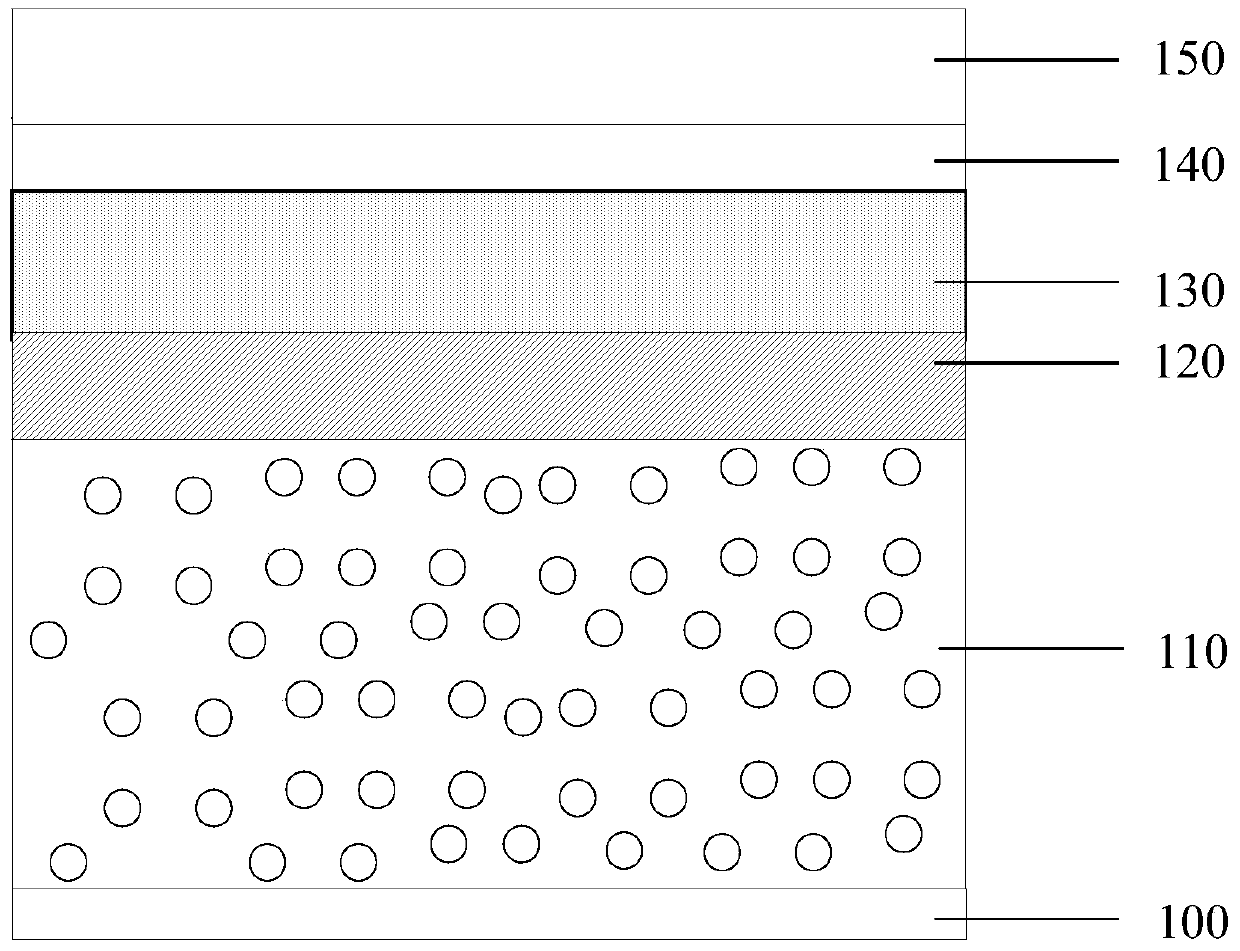

[0039] As described in the background art, during the formation process of the existing interconnect structure, there is a problem that the conductive plugs are prone to overhang in each stacked structure, resulting in the formation of the conductive plugs, the interlayer dielectric near the conductive plugs The layers are highly prone to voids, which degrade the quality and reliability of the interconnect structure.

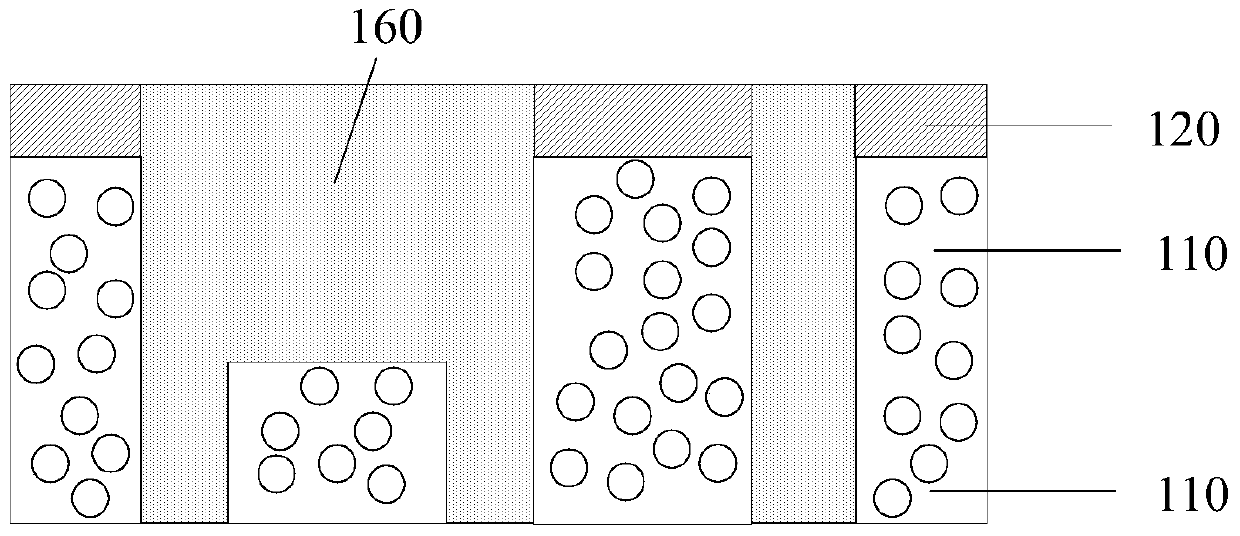

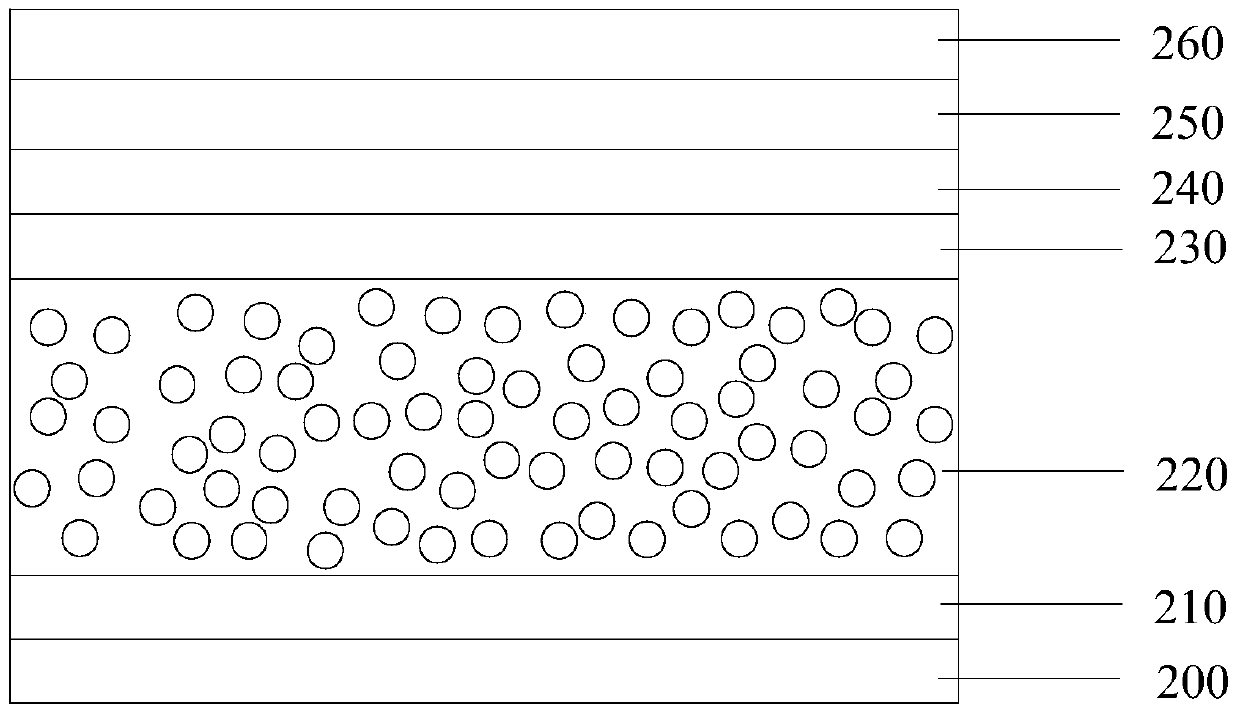

[0040] The present invention provides a new interconnection structure and a method for forming the same. The forming method forms a dense dielectric layer on the ultra-low K dielectric layer. The dense dielectric layer itself has a protective function, so it is not necessary to form the protective layer, and then the dense dielectric layer is formed on the dense dielectric layer. A mask layer is formed on the layer, and then the mask layer, the dense dielectric layer and the ultra-low K dielectric layer are sequentially etched from top to bottom until through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com