Aluminum alloy sheet with excellent baking-paint curability

一种铝合金板、放热峰值的技术,应用在Al-Mg-Si系铝合金板领域,能够解决铝合金板高屈服强度、难以具有烘烤涂装硬化特性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

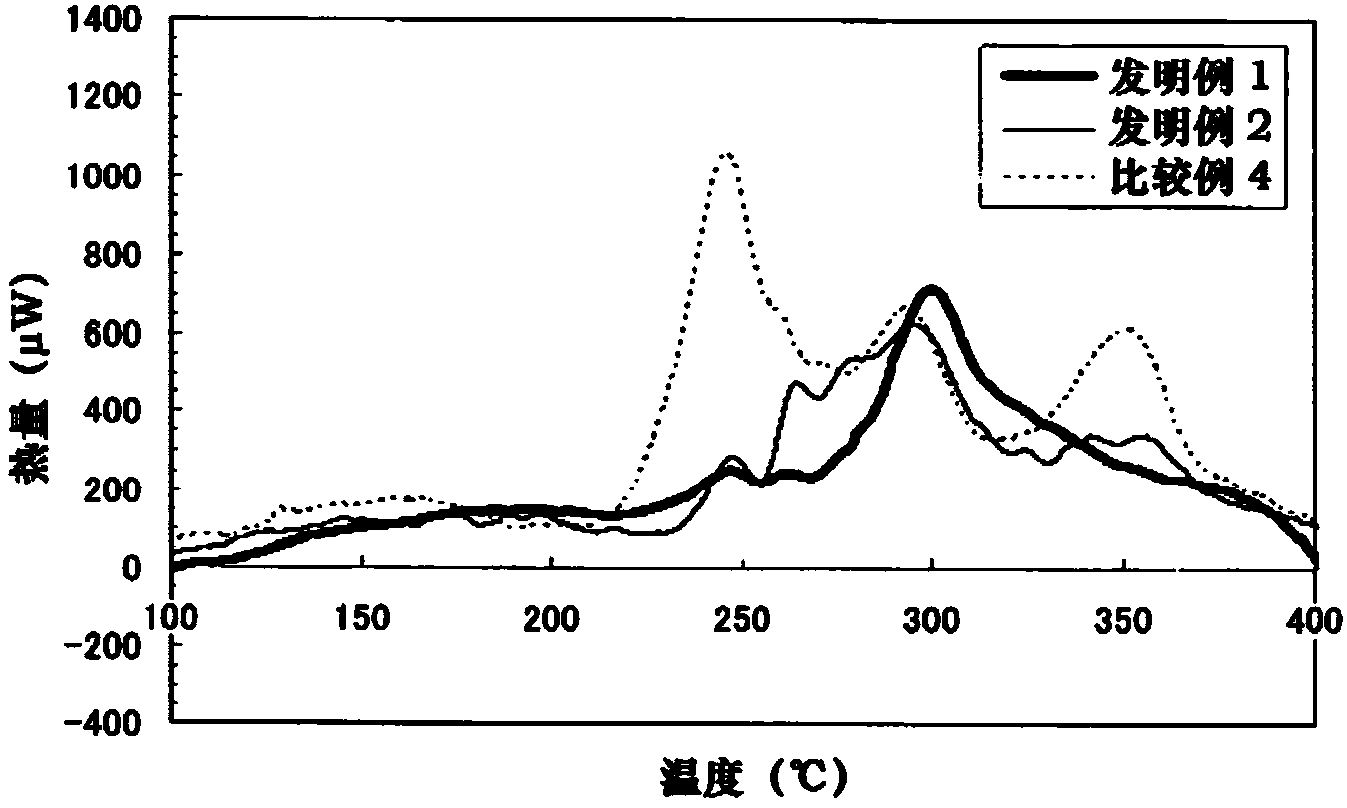

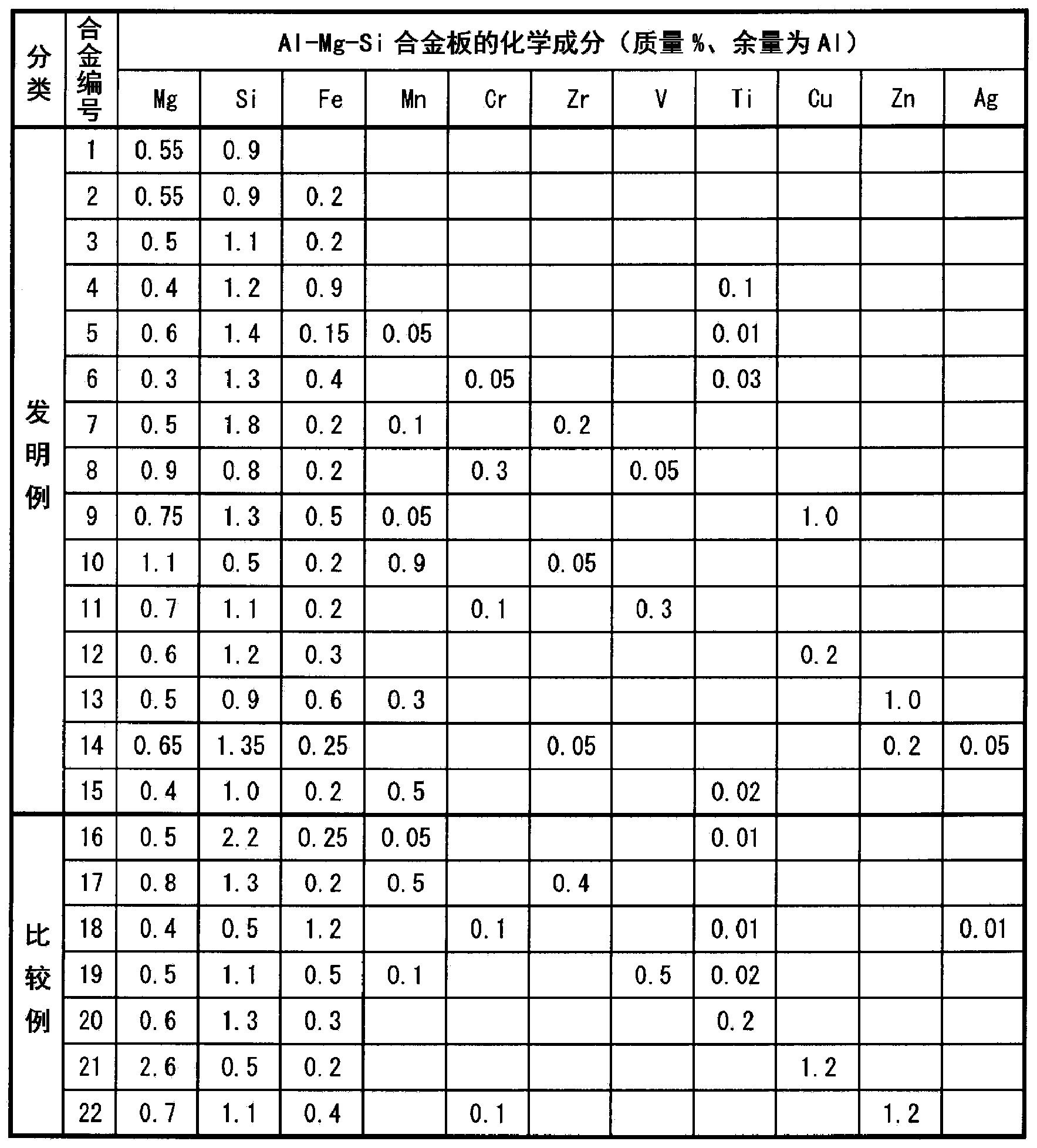

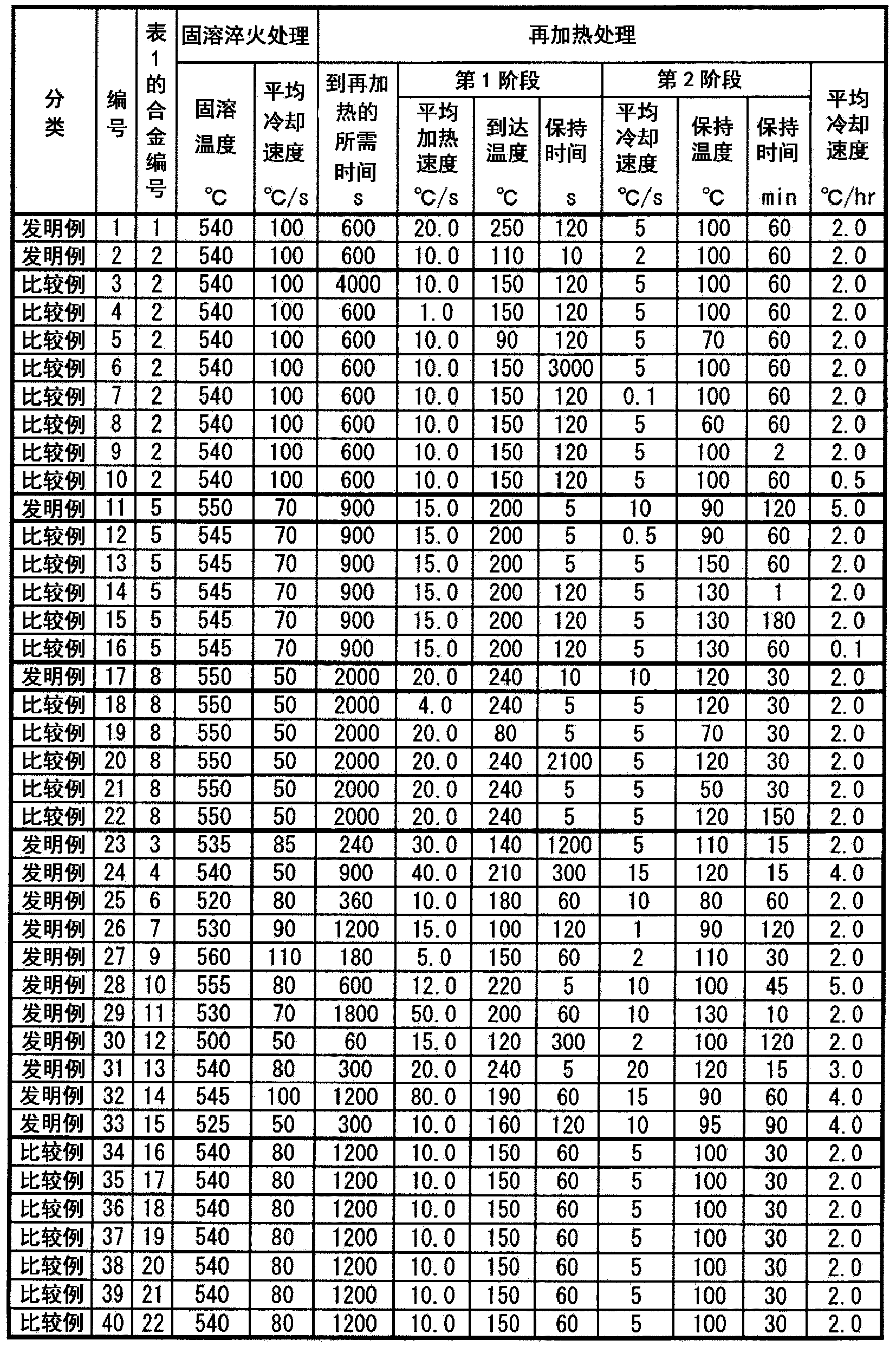

[0106] Next, examples of the present invention will be described. Under the conditions of reheating treatment after solid solution and quenching, 6000 series aluminum alloy plates with different heights of exothermic peak heights A, B, and C in the DSC specified in the present invention were produced separately, and the quenching and tempering were evaluated respectively. BH property (coating bake hardening property) in a short period of time after low temperature. In addition, hemming workability, which is press formability and bending workability, was also evaluated.

[0107] The above classification was made as shown in Table 2, the reheating treatment conditions after the solution and quenching treatment, the heating temperature (°C) (referred to as the reaching temperature in Table 2), the holding time (hr), especially these heating holding The subsequent cooling conditions were changed variously to manufacture 6000-series aluminum alloy sheets having the compositions sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| longitudinal tensile yield strength | aaaaa | aaaaa |

| longitudinal tensile yield strength | aaaaa | aaaaa |

| longitudinal tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com