Airflow buffer

A technology of airflow buffering and feed inlet, which is applied in the direction of separating solids from solids by airflow, chemical instruments and methods, solid separation, etc., can solve the problems of large amount of mixed materials and high classification accuracy, and improve the efficiency of processing materials ability, improved accuracy, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

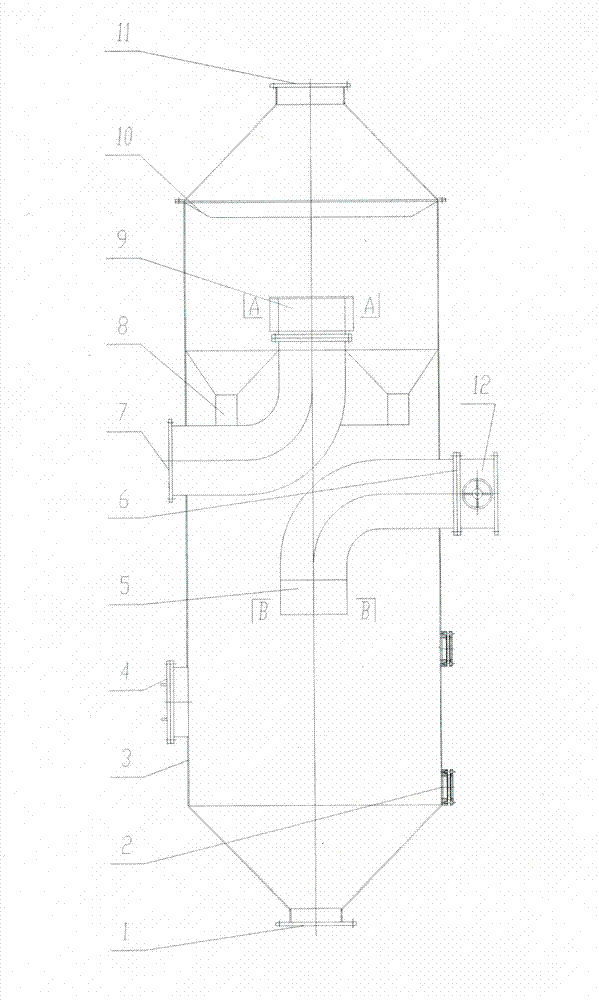

[0010] see figure 1 , the airflow buffer consists of a cylinder 3, an upper discharge port 11, a lower discharge port 1, a conical ring 10, a secondary air classification collar 8 for granular materials, a feed pipe, an air inlet pipe, a sight glass 2, and a manhole 4 and so on. The mixture of 120 mesh and above enters the feed inlet 7 with the airflow, and reaches the upper mixture sprinkler impeller 9 through the feed pipe. The mixture is evenly sprinkled around the upper chamber through the sprinkler impeller 9. Particles and dust are discharged from the discharge port 11 along with the ascending airflow, 120 mesh and a small amount of particles above 120 are thrown, and after hitting the wall of the container, they are collected in the secondary air classification collar 8 along their respective descending routes under the action of gravity. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com