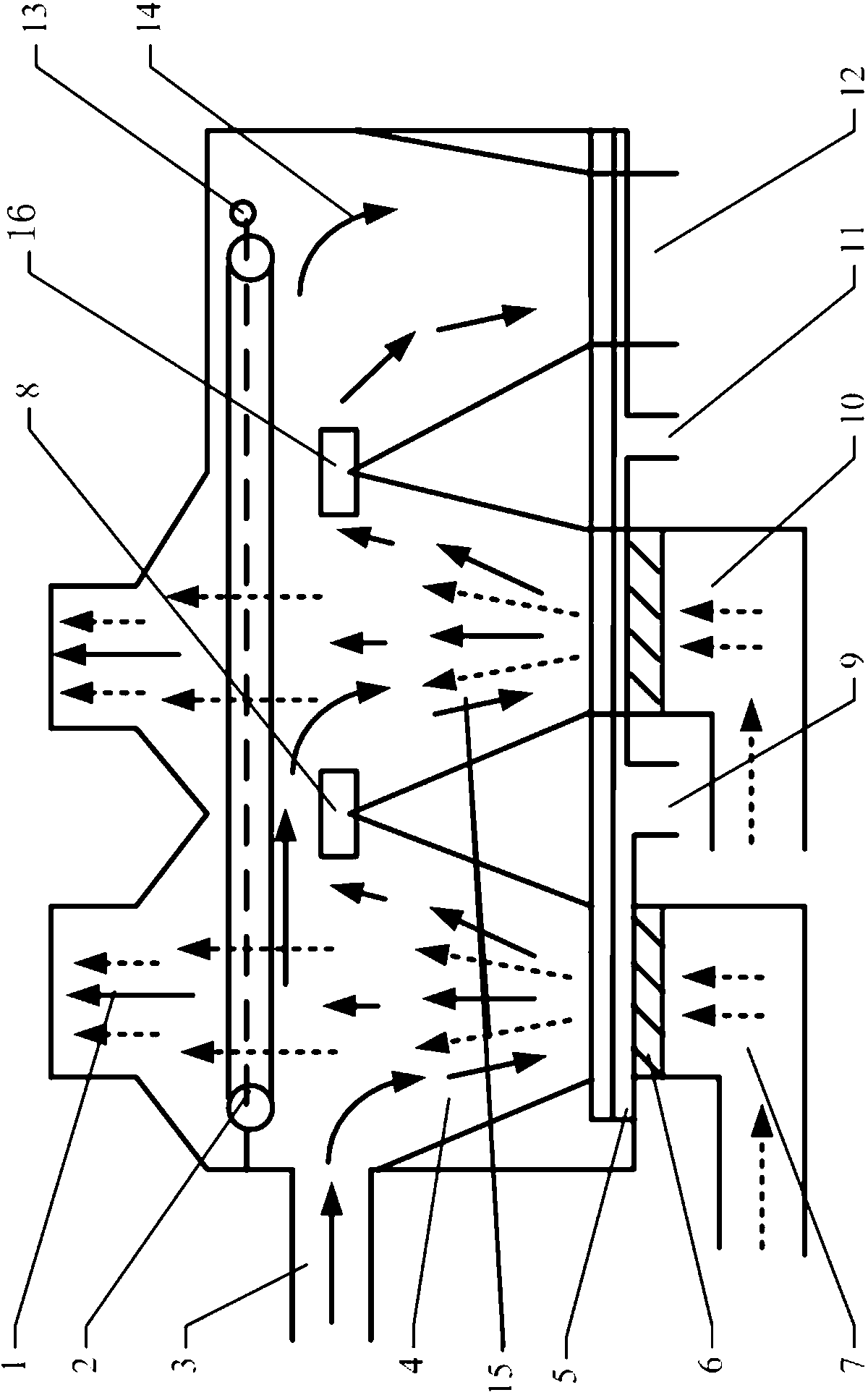

Wind pressure type three-cabin wind separator

An air separator and air pressure technology, applied in the direction of solid separation, chemical instruments and methods, separating solids from solids with airflow, etc., can solve the problem of reducing the use value of materials, reducing the size of materials, and intense mechanical friction, etc. problems, to achieve the effect of reducing air volume for sorting, low material loss, and reducing equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The material of the present invention enters the separation bin through the conveyer belt or vibrating screen and enters the separation bin from the feed inlet, wherein the dust and debris with a size smaller than the mesh size of the conveyor mesh belt passes through the conveyor mesh belt in the separation bin under negative pressure and is sucked The tuyere dust removal system eliminates all difficulties; the loose and lighter materials larger than the mesh of the conveyor belt are adsorbed on the bottom of the conveyor belt by negative pressure; the remaining heavy materials are lifted by positive pressure and wind during the falling process Float, gradually loosen and separate from the heavier materials, and then lifted to the pressure balance surface by the positive pressure wind, and then adsorbed on the conveyor belt by the negative pressure; the remaining materials fall on the bottom vibrating screen and are transported by vibration. Under the combined action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com