A Method for Remediating Organic Polluted Solid Waste Using Microwave Technology

An organic and microwave technology, applied in the restoration of polluted soil and other directions, can solve the problems of high equipment investment and operating costs, adverse effects of soil regeneration and utilization, and high pressure on secondary pollution control. The effect of improving the heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

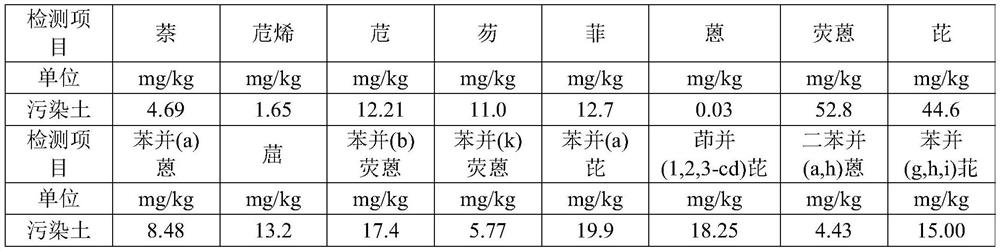

[0045] The composition of the sandy organic polluted soil treated is shown in Table 1.

[0046] Table 1 Composition of organic polluted soil (sandy soil) to be treated

[0047]

[0048] The first step: the material is screened, iron-removed and crushed, and there are no particles larger than 20mm in the processed material;

[0049] The second step: add auxiliary heating balls to the processed materials, and mix the cloth. Take 30kg of sandy organic polluted soil whose composition is shown in Table 1, mix it according to the ball-to-material ratio of 1:2, and spread it evenly.

[0050] Step 3: Heat the material with auxiliary heating pellets in a microwave oven with a power of 20kW. After preheating and high-temperature thermal desorption, the temperature is raised to 500-550°C and then kept at a constant temperature.

[0051] Step 4: After the constant temperature, the material is cooled and pushed out, and the material is discharged.

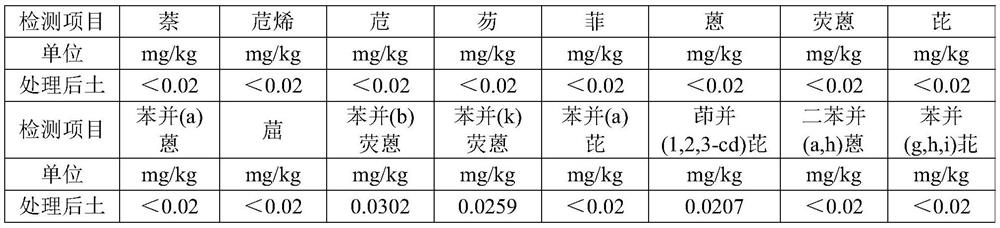

[0052] The components of the soil ...

Embodiment 2

[0056] See Table 3 for the components of the treated clay-organic contaminated soil.

[0057] Table 3 Composition of organic polluted soil (clay soil) to be treated

[0058]

[0059]

[0060] The first step: the material is screened, iron-removed and crushed, and there are no particles larger than 20mm in the processed material;

[0061] The second step: add auxiliary heating balls to the processed materials, and mix the cloth. Take 30kg of viscous organic polluted soil whose composition is shown in Table 3, mix it according to the ratio of ball to material 1:2.5, and spread it evenly.

[0062] Step 3: Heat the material with auxiliary heating pellets in a microwave oven, preheat and heat up at a power of 25kW, and desorb at a high temperature.

[0063] Step 4: After the constant temperature, the material is cooled and pushed out for discharge.

[0064] The components of the soil after microwave treatment all meet the national standards, and the results are as follows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com