Anti-blocking printing spraying head of FDM three-dimensional printer

A 3D printer and printing nozzle technology, applied in the field of 3D printers, can solve the problems of material denaturation, printing nozzle clogging, nozzle clogging, etc., to achieve the effects of fast melting, improved stability, and reduced heating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

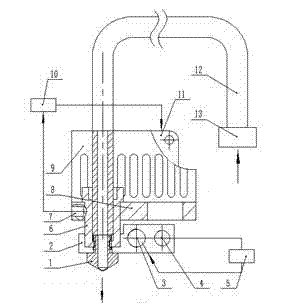

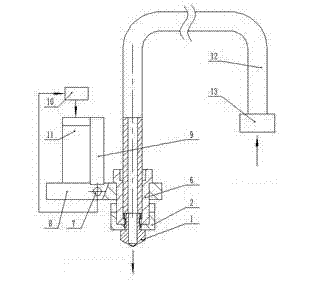

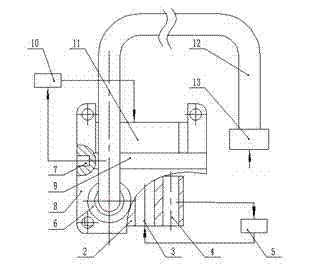

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] An anti-blocking printing nozzle of a fused deposition type (FDM) 3D printer, including a printing nozzle, a heating aluminum block, an electric heating tube, a heating temperature control main board, a heating temperature sensor, a feeding pipe, and a feeder, and is characterized in that it is equipped with Thin heating aluminum block, T-shaped preheating aluminum block and constant temperature aluminum block. The T-shaped preheated aluminum block is passed to the constant temperature aluminum block. The thin heating aluminum block, the T-shaped preheated aluminum block and the constant temperature aluminum block are provided with feeding tube insertion holes. The printing nozzle on the heating aluminum block is connected, and the other end is connected to the feeder. The printing nozzle is installed on the thin heating aluminum block, and the T-shaped preheating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com