Temperature changing pigment packaging and drying device

A technology of drying device and temperature-changing pigments, applied in printing, printing presses, general parts of printing machinery, etc. The effect of waste generation, cost reduction and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

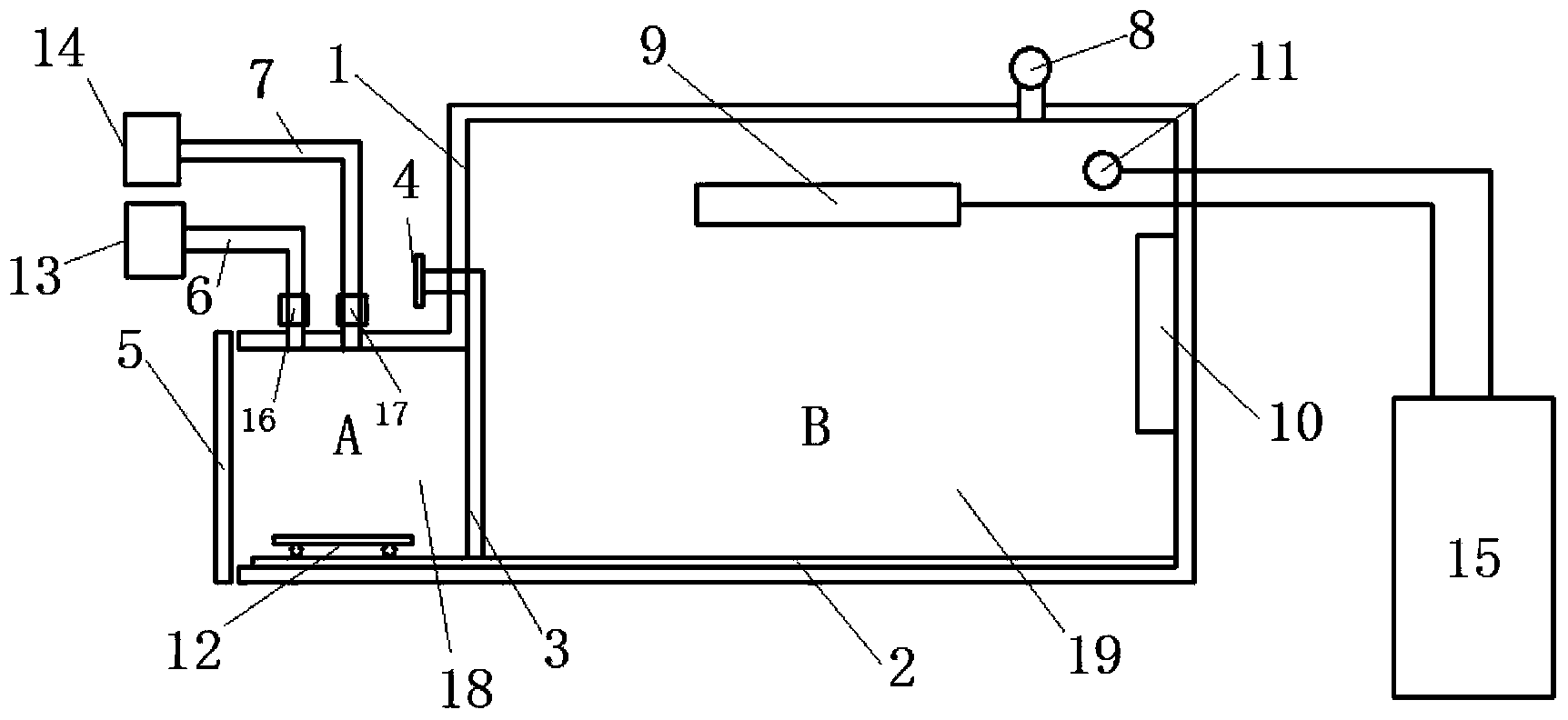

[0011] A temperature-changing pigment packaging and drying device, including a box body 1, the box body 1 is divided into an A cavity 18 and a B cavity 19 by a metal partition 3, a sealed door 5 is arranged at the opening of the A cavity 18, and the A cavity 18- There are air inlet and exhaust port on the side, in which the exhaust port, relay I16 and vacuum pump 13 are connected through exhaust pipe 6, the air inlet, relay II17 and argon cylinder 14 are connected through air inlet pipe 7, and the metal partition 3 is connected The handle 4 is used to control the closure of the metal partition 3; a heating device 9, a lighting lamp 10 and a temperature measuring device 11 are arranged in the chamber B, and a barometer 8 is arranged outside the chamber, and the heating device 9 and the temperature measuring device 11 Connected with the console 15, the bottom of the box body 1 is provided with a guide rail 2, and the loading vehicle 12 can move along the guide rail. The heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com