Safe tightening device with a pre -increased car

A tensioning device and automobile safety technology, which is applied in the direction of freight vehicles, motor vehicles, bicycle accessories, etc., can solve the problems of pushing ratchets and easily feeling tired, so as to improve economic benefits, reduce time-consuming tying operations, and improve The effect of labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

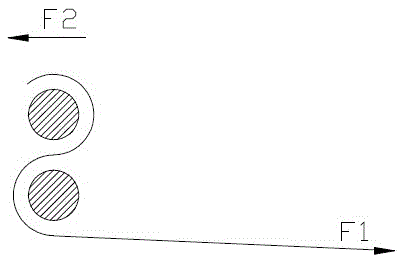

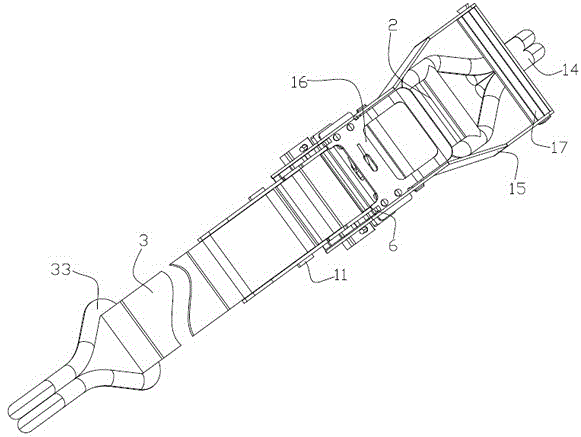

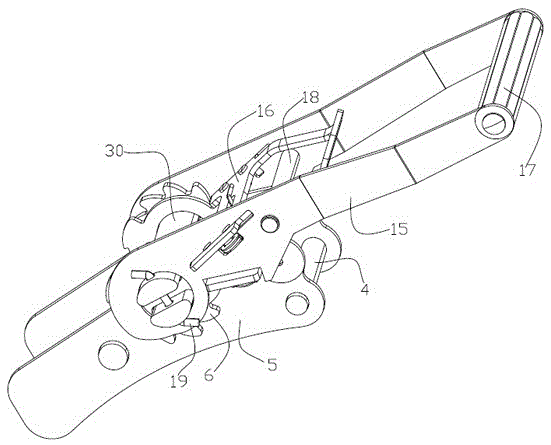

[0027] Such as figure 2 As shown, a kind of pre-tension multiplied automobile safety tightening device provided in this embodiment includes a tensioning device host 1 with a main shaft 30, a short strap 2 and a long strap 3, such as Figure 3-7The main body 1 of the tensioning device is mainly composed of a handle assembly and a base assembly; wherein, the base assembly includes a pair of base side plates 5, a pair of ratchets 6, A stop pawl 7 and a stop pawl torsion spring 8, the main rotating shaft 30 is located between a pair of base side plates 5, and its two ends respectively pass through the corresponding base side plates 5 and then drive and socket A ratchet 6 is symmetrically provided with a pair of first sliding grooves 9 on the pair of base side plates 5, and a first pin 10 is provided on the bottom surface of one of the first sliding grooves 9, and the stop pawl 7 penetrates In the pair of first sliding grooves 9, and can slide in the first sliding grooves 9, the ...

Embodiment 2

[0032] Such as Figure 9-11 As shown, a kind of pre-tension force multiplied automobile safety tensioning device provided in this embodiment has a general structure consistent with that of Embodiment 1, but since the long strap 3 has long and short specifications, when in use, the binding There are large and small goods. If a very long strap 3 is used to bind a small cargo, and the strap must start from the head of the long strap 3, it will inevitably affect the binding speed and affect the work. efficiency. Therefore, a pair of base side plates 5 in this embodiment are also provided with a pair of strip-shaped grooves 22 symmetrically. A bolt fastening set 23 runs through the movement. The long strap 3 is folded and forms a first collar 13 at the folded place. The bolt fastening set 23 is connected in series in the first collar 13. Moreover, both ends of the long strap 3 extend outwards after bypassing the first pivot pin 11 , and one of the two outwardly extending ends is ...

Embodiment 3

[0035] A kind of pre-tension multiplied automobile safety tightening device provided in this embodiment, its general structure is consistent with embodiment 2, as Figure 12 shown, but the bolt fastening kit 23 in this embodiment includes bolts 26 and nuts 27, any one of the two bar-shaped grooves 22 has a large and small circle intersecting structure, and the large circle part 24 is located on the small The outer side of the round part 25, wherein the screw part 28 of the bolt 26 passes through the two strip grooves 22, and extends out of the base side plate 5, and its bolt head part 29 is in contact with the outer wall of the base side plate 5 on the corresponding side. , the nut 27 is screwed on the screw part 28 until it abuts against the outer wall of the base side plate 5 on the corresponding side, and the maximum outer diameter of the nut 27 is greater than the inner diameter of the small circle part 25, but smaller than that of the large circle part 24 inner diameter v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com