Double-sided adhesive tape

A double-sided tape and rubber technology, applied in the field of construction and decoration, can solve problems such as difficult to move, inaccurate pasting position of double-sided tape, inaccurate pasting position of decoration materials, etc., and achieve the effect of easy construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

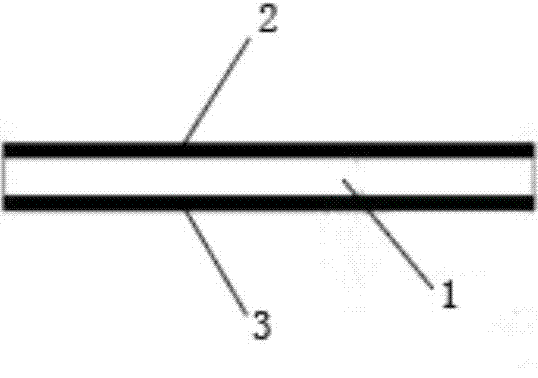

[0024] Figure 1a and Figure 1b They are the structure diagram of the prior art double-sided adhesive tape and the reference diagram of the state of use of the prior art double-sided adhesive tape respectively. It can be seen from the figure that the prior art double-sided adhesive tape is not designed as a special-shaped end face, but is in a planar structure. When in contact with the finish layer, the adhesive layer and the finish layer are instantly bonded and cannot be moved anymore, which will cause inaccurate pasting positions.

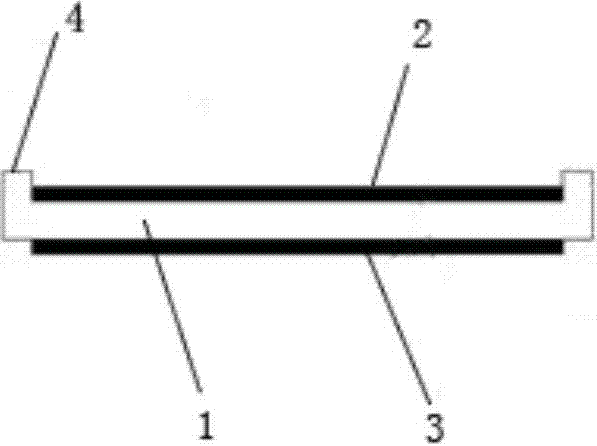

[0025] figure 2 A kind of double-sided adhesive tape provided by the present invention includes a substrate 1, a first adhesive layer 2 and a second adhesive layer 3, from top to bottom the first adhesive layer 2, the substrate 1, and the second adhesive layer 3 There are protrusions 4 at both ends of the base 1, the base 1 and the protrusions 4 form an L-shaped structure, and the level of the protrusions 4 is higher than the level of the fir...

Embodiment 2

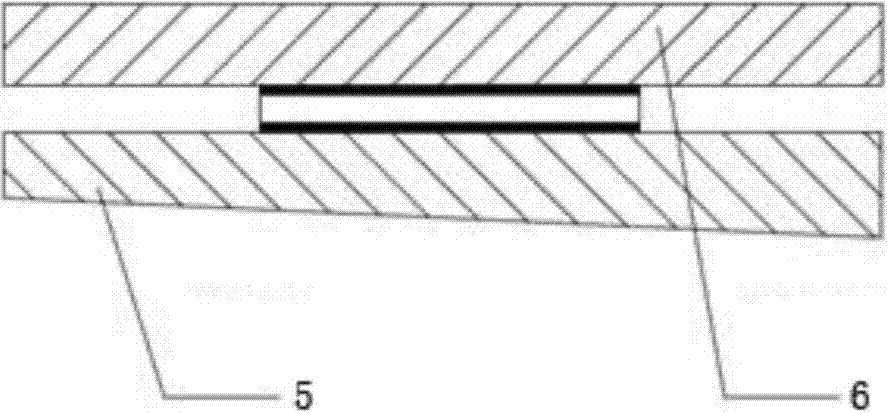

[0030] Such as Figure 4 As shown, the dotted rectangular part is the double-sided adhesive tape provided by the present invention. Since there are many veneer layers 6 to be bonded, it is required to be bonded neatly and beautifully.

[0031] When bonding, a group of double-sided adhesive tapes in the vertical direction are first fixed on the base layer 5 (because the double-sided adhesive tape is hidden between the base layer 5 and the finish layer 6, the position of the double-sided adhesive tape may not be very accurate), After fixing, cover the facing layer 6 on the double-sided adhesive tape, move the facing layer 6 up and down, left and right to make the facing layer 6 neat and accurate (such as Figure 4 (indicated by the middle arrow), after the position is adjusted, pressure is applied to the finish layer 6, the protrusion 4 on the double-sided adhesive tape is deformed, the finish layer 6 is in contact with the first adhesive layer 1, and the finish layer 6 It's fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap