Drying and temperature-controlling device for ballast and operating method thereof

A ballast and drying technology, applied in the direction of ballast layer, road, track, etc., can solve the problems of ballast track bed drying, and achieve the effect of improving drying and temperature control efficiency and small thermal inertia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

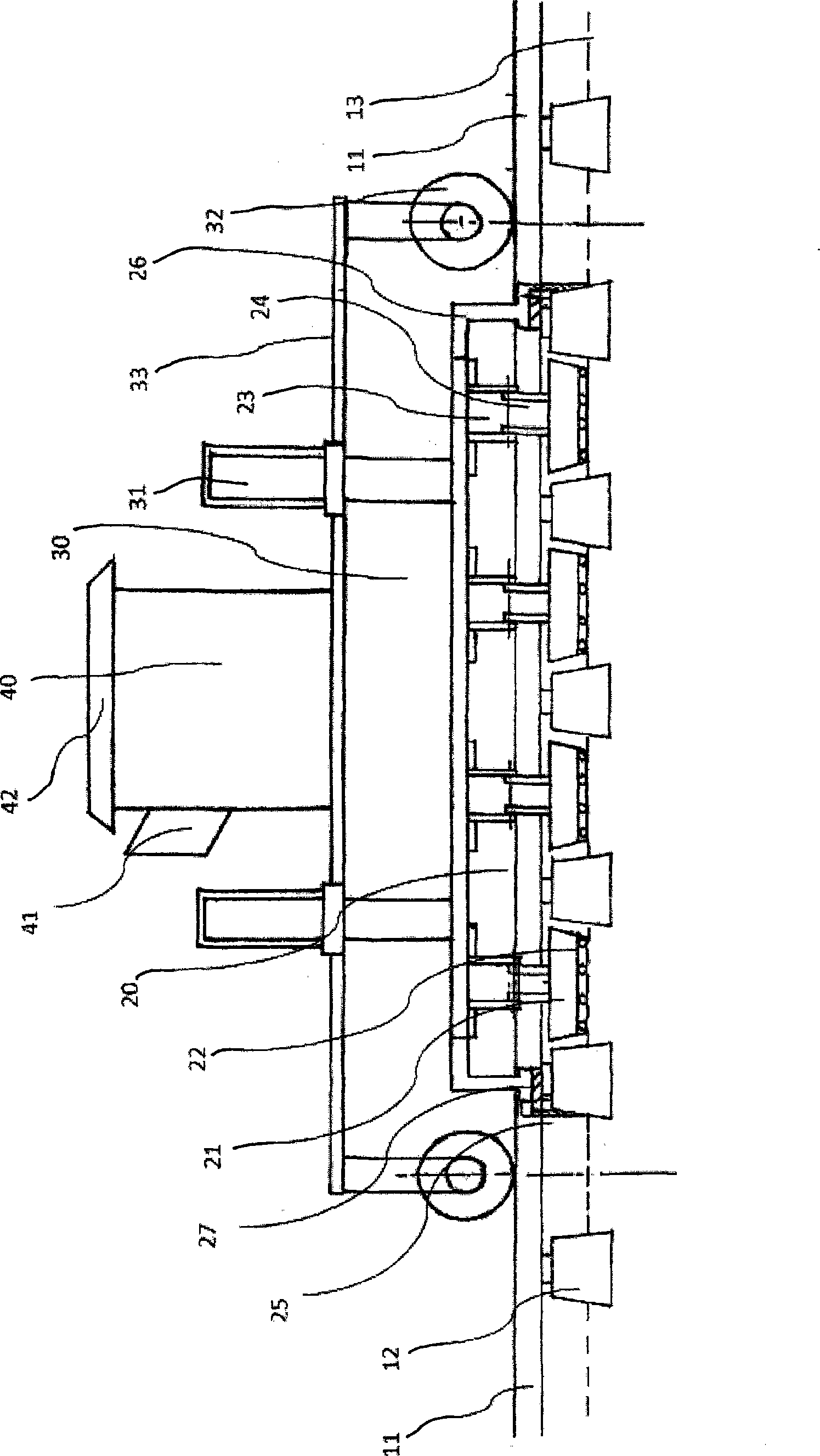

Embodiment 1

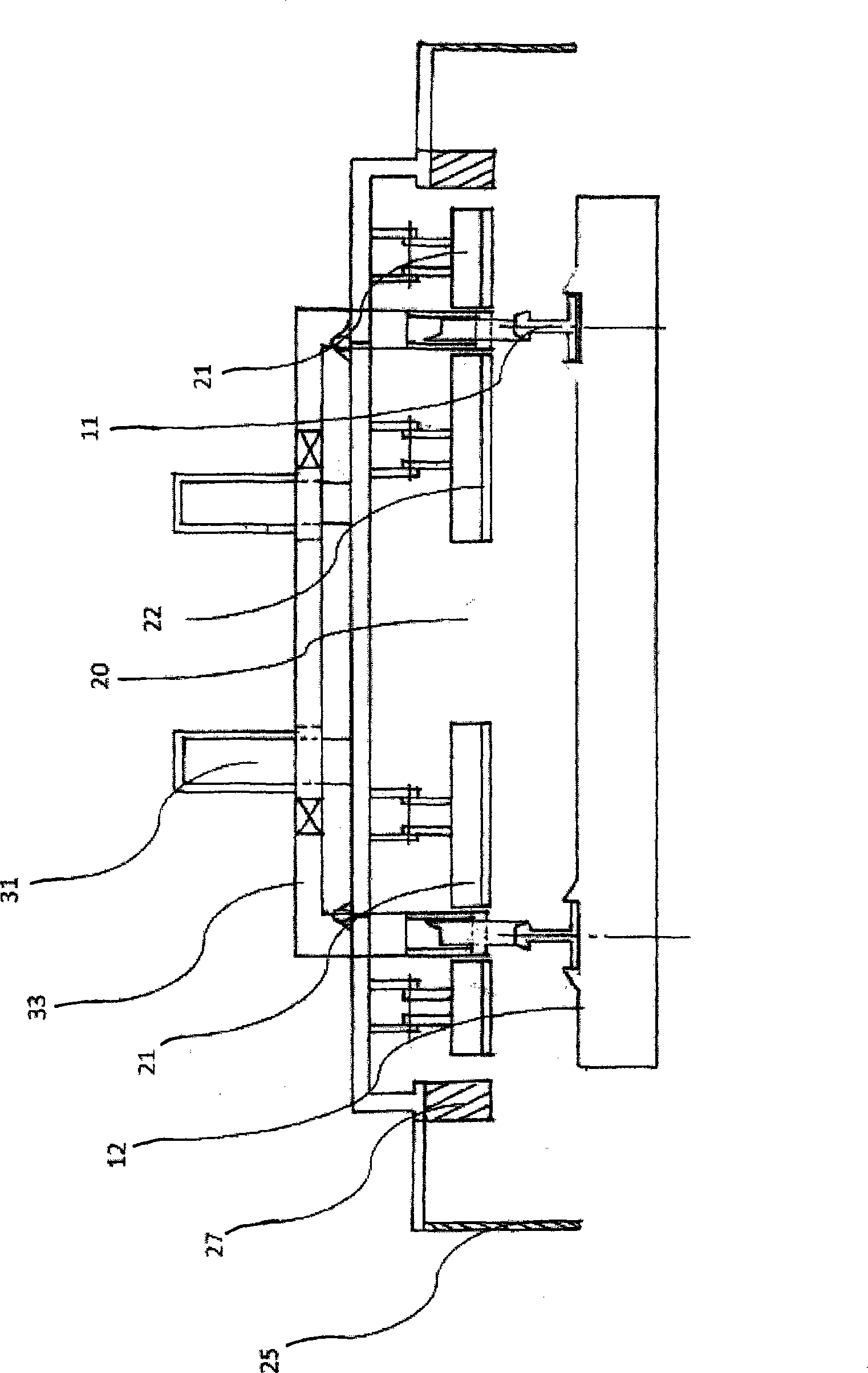

[0047] See Figure 4 , The microwave heating part 20 of the device of the present invention can be selected as a household small magnetron 23 of 2540MHz, and the power of the magnetron is 2KW to 5KW. This kind of magnetron is small in size, and can form a small microwave generator together with the waveguide 24 , the radiating resonant cavity 21 and the homogenizer 22 , and output microwaves from the homogenizer 22 . In this embodiment, the microwave heating component 20 is composed of a series of small microwave generators connected in series and parallel. Such as Figure 4 As shown, the microwave heating unit 20 includes four rows of microwave heating generators equally spaced, and the space is approximately equal to the space between sleepers. Each row of microwave generators consists of four microwave generators, which are symmetrically distributed along the centerline of the rail. For example, in Figure 4 Among them, the larger microwave generators are symmetrically ...

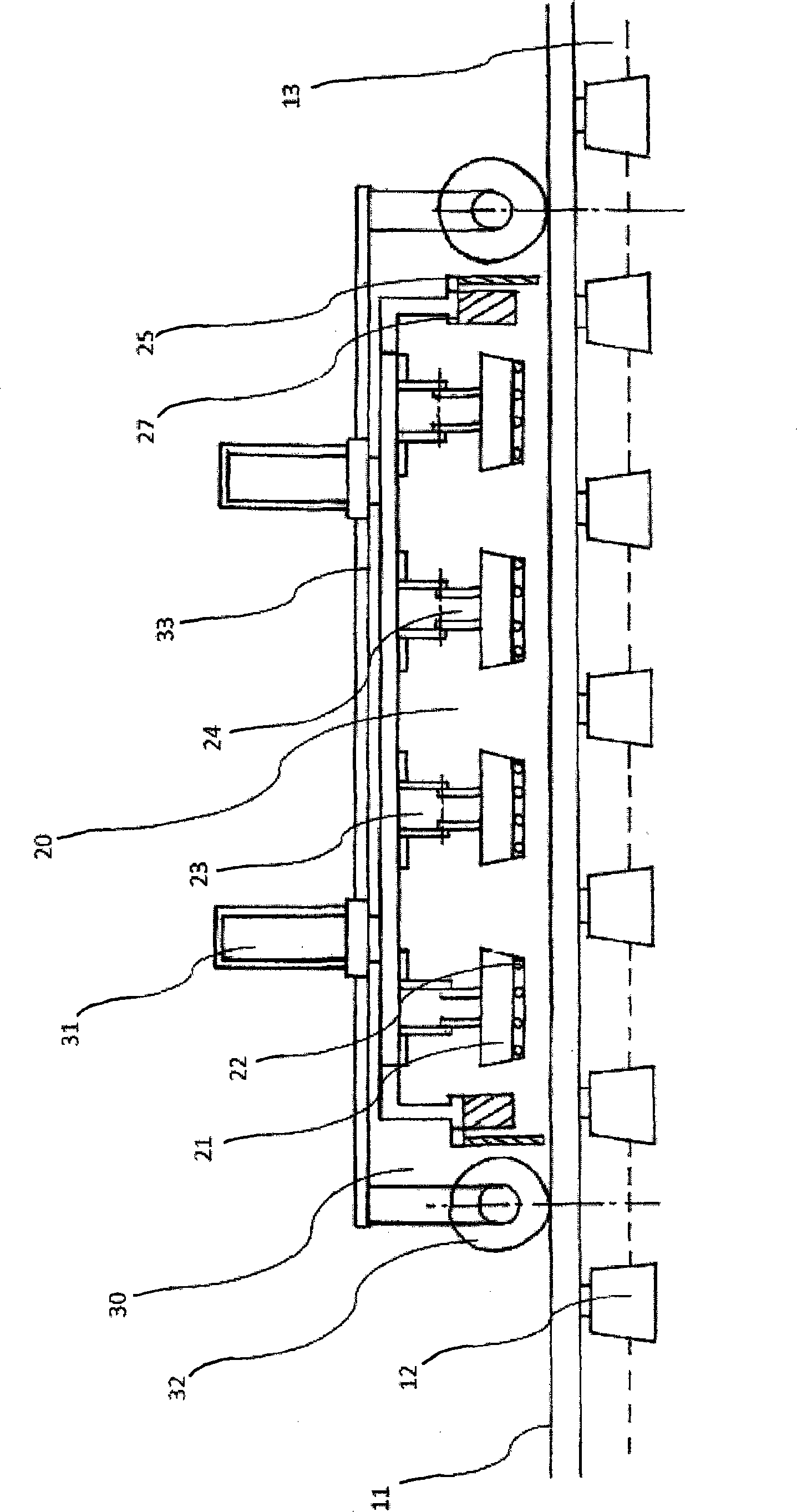

Embodiment 2

[0049] See Figure 5 , The microwave heating part 20 of the device of the present invention can be selected the industrial large-scale magnetron 29 of 915MHz, and the power of this magnetron is 75KW to 100KW. Due to the huge volume of the 915MHz magnetron, this magnetron can be arranged at the rear end of the microwave heating component 20 . Generally speaking, in order to avoid waste of microwaves, 2 to 4 magnetrons 29 can be connected in series and parallel according to the construction speed requirements, and the microwaves can be introduced into the radiation type resonant cavity 21 and homogenizer 22 through the bifurcated waveguide combination 281 .

[0050] Such as Figure 5 As shown, one end of the bifurcated waveguide assembly 281 is connected to the resonant cavity 21, and the other end is connected to the magnetron 29 through the circulator 282. In this technical field, a circulator is a non-reciprocal transmission element, usually used to connect a microwave sour...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap