Concrete-filled steel tubes against peeling damage

A steel tube concrete and concrete technology, applied in the direction of pillars, pier columns, columns, etc., can solve the problems of reducing bearing capacity and stability, poor concrete compactness, and reducing the fluidity of self-compacting concrete, so as to avoid peeling damage and improve stability and shock resistance, the effect of reducing shrinkage strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

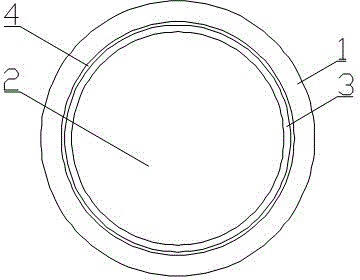

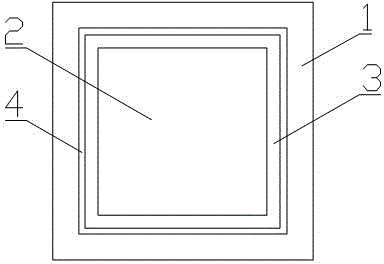

[0014] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , figure 2 As shown, the concrete-filled steel pipe for preventing peeling damage includes steel pipe 1 and concrete 2, and a geotextile layer 3 is arranged between the steel pipe 1 and the concrete 2, and the geotextile layer 3 is arranged close to the inner wall of the steel pipe 1, and the geotextile layer 3 It is connected with the inner wall of the steel pipe 1 through structural glue 4 .

[0015] The geotextile layer 3 is polyester filament geotextile.

[0016] The present invention is achieved like this:

[0017] 1. Compare the performance parameters of various structural adhesives, and select the structural adhesive with higher tensile strength, so as to ensure the firm connection between the geotextile and the steel pipe wall.

[0018] 2. Compare the performance parameters of various geotextiles, and choose the geotextile with stronger transverse tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shrinkage stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com