Split type fire valve

A fire-fighting valve, segmented technology, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as valve damage, and achieve the effect of preventing man-made damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

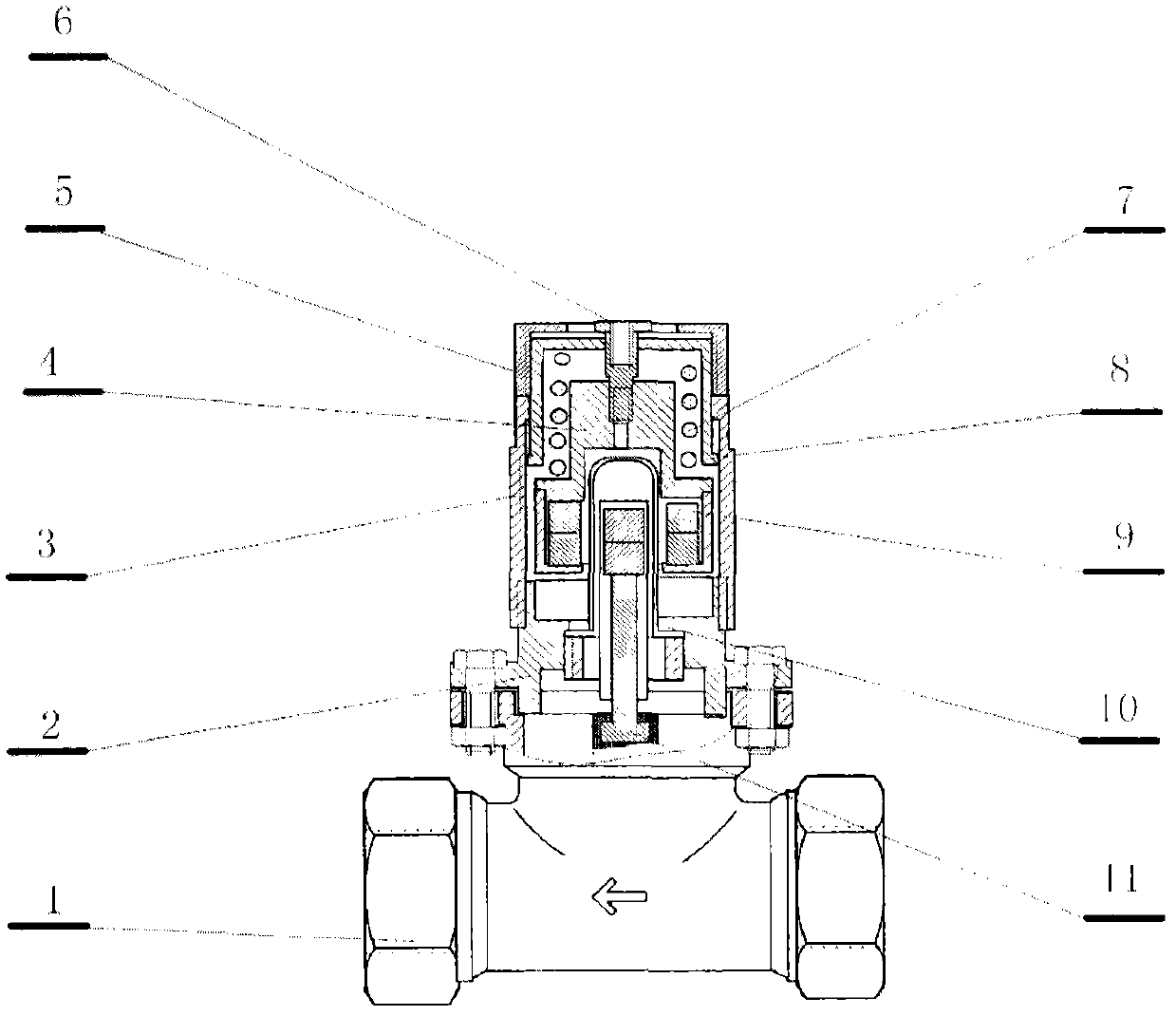

[0008] The accompanying drawing is a schematic structural diagram of the present embodiment. It is mainly composed of two parts: the valve body and the temperature control head, including the valve body (1), valve cover (2), valve cap (3), linkage (4), valve cover (5), linkage bolts (6) , return spring (7), linkage cap (8), outer magnetic assembly (9), spool sleeve (10), spool (11), connecting bolt (12), bolt cover (13), memory alloy (14 ) thermal insulation pad (15); the lower part of the spool (11) is equipped with a piston, the piston cooperates with the water outlet in the valve body (1) to open and close the valve, and the upper part of the spool (11) is inlaid with an internal magnetic assembly, and Inserted in the spool cover (10) connected with the bonnet (2), the spool cover (10) is covered with an outer magnetic assembly (9), and the upper part of the outer magnetic assembly (9) is connected with the linkage (4) ) connection; the upper part of the linkage (4) is cov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap