Automatic control energy-saving system and control method

An energy-saving system and control method technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of increasing energy consumption of running air compressors, increasing false demand, frequent loading and unloading of air compressors, etc. , to achieve the effect of reducing energy consumption and stabilizing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention and corresponding drawings.

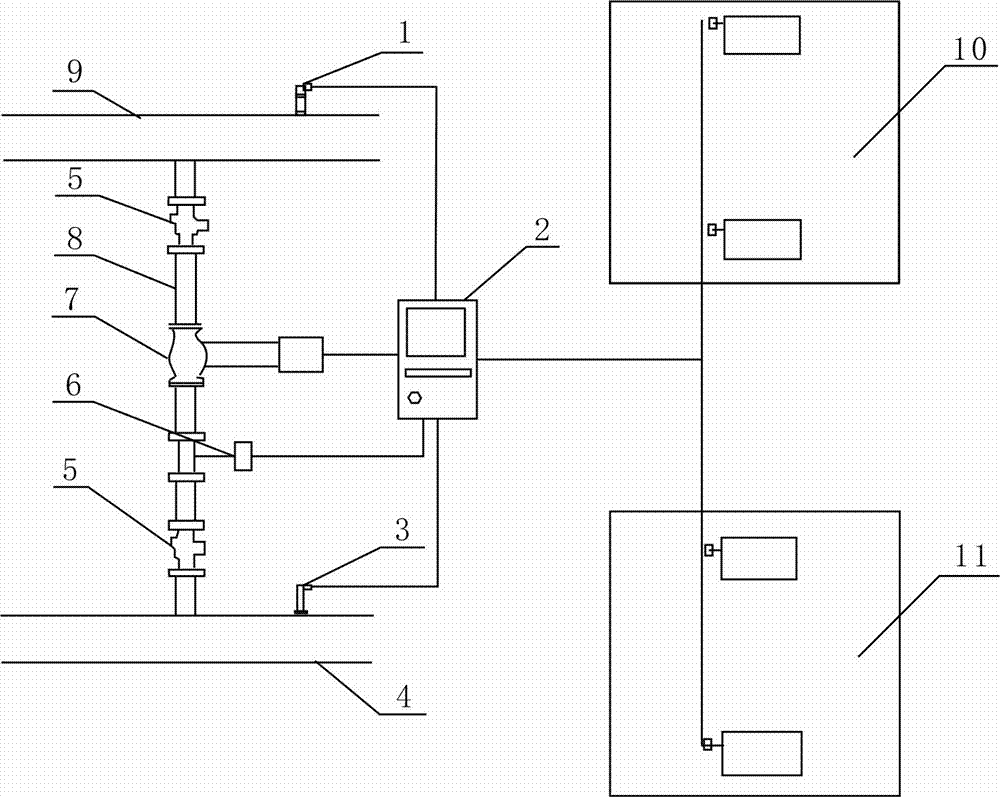

[0027] refer to figure 1 , figure 1 Shown is the connection diagram of the automatic control energy-saving system of this embodiment; the system includes a low-pressure pipeline 4, a high-pressure pipeline 9, a high-pressure air compressor unit 10, a low-pressure air compressor unit 11, a connecting pipeline 8, a first pressure transmission Device 1, second pressure transmitter 3, optimization control module 2, regulating valve 7, flow meter 6 and ball valve 5.

[0028] The high-pressure pipeline 9 is connected to the high-pressure air compressor unit 10, the low-pressure pipeline 4 is connected to the low-pressure air compressor unit 11, and the first pressure transmitter 1 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com