Vortex flooded direct cooling unit for parallel shared system dedicated to surface treatment industry

A surface treatment and shared system technology, applied in the direction of refrigerators, refrigeration components, compressors, etc., can solve problems such as unfavorable cleaning and maintenance, dirty corrosive refrigerants, and increase intermediate links, etc., to achieve convenient cleaning and maintenance, high energy efficiency , to avoid the effect of running oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

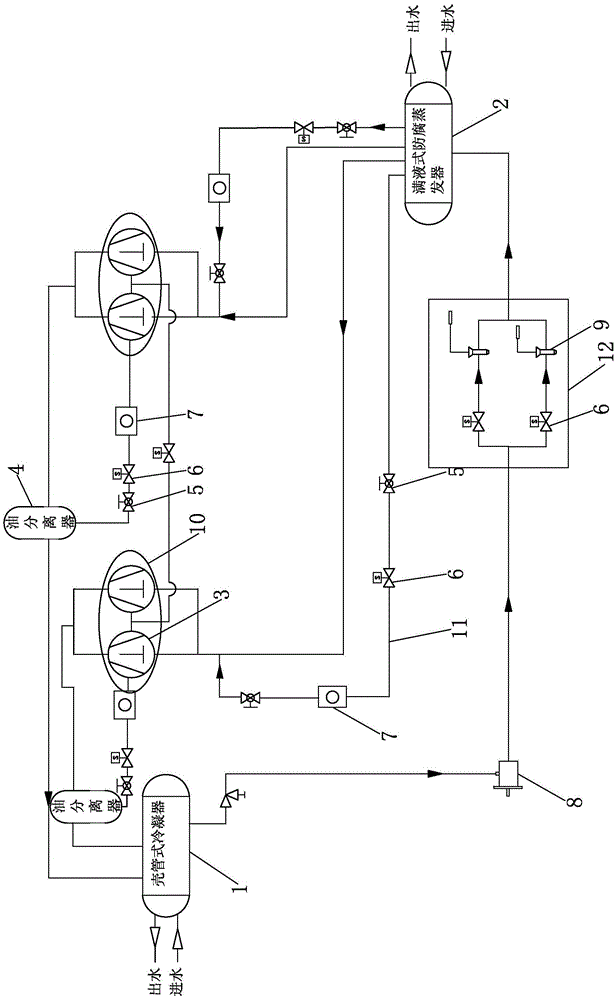

[0017] Embodiment: a kind of special-purpose parallel shared system vortex flooded direct cooling unit for the surface treatment industry, such as figure 1 As shown, it includes a shell-and-tube condenser 1, a flooded anti-corrosion evaporator 2, and a first piping system and a second piping system connected between the two, and the first piping system and the second piping system form a closed loop.

[0018] The first pipeline system includes two scroll compressor units 10 connected in parallel, and each scroll compressor unit 10 includes a plurality of refrigeration compressors 3 connected in parallel connected by pipelines and an oil separator 4. The refrigeration compressor 3 is connected to the flooded anti-corrosion evaporator 2, the oil separator 4 is connected to the shell-and-tube condenser 1, and an oil return pipeline is also connected between the oil separator 4 and the refrigeration compressor 3; The oil pipeline includes a ball valve 5 , a solenoid valve 6 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com