An oil return structure and its ascending steam return standpipe oil return device

A riser and pipeline technology, applied in the field of oil return structure and its rising steam return riser oil return device, can solve problems such as difficulty in oil return, and achieve the effect of ensuring oil return efficiency, compact structure and high oil return efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

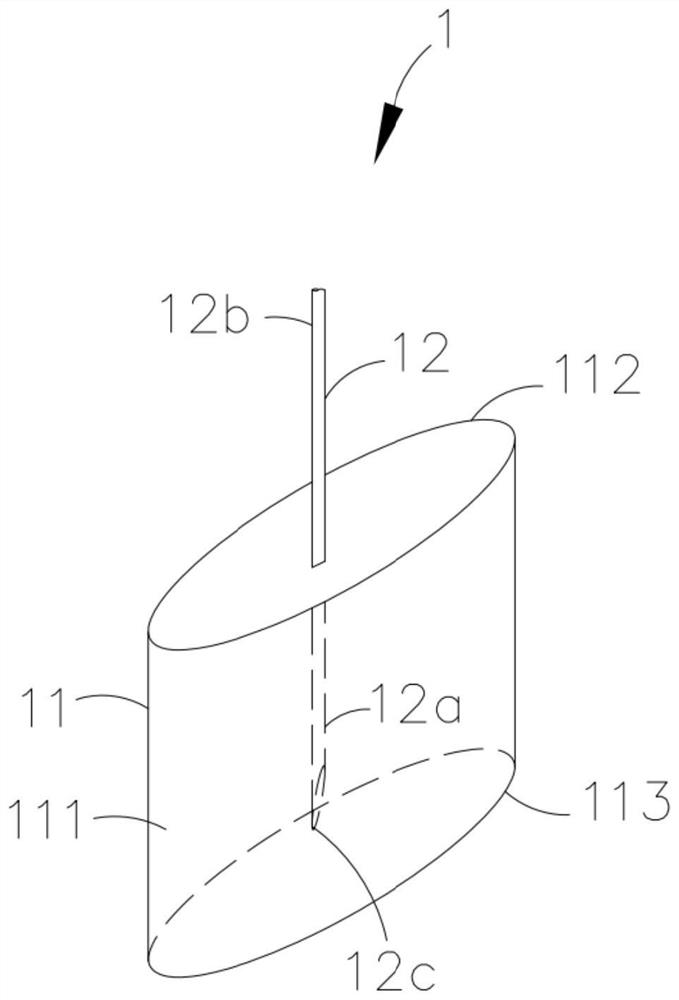

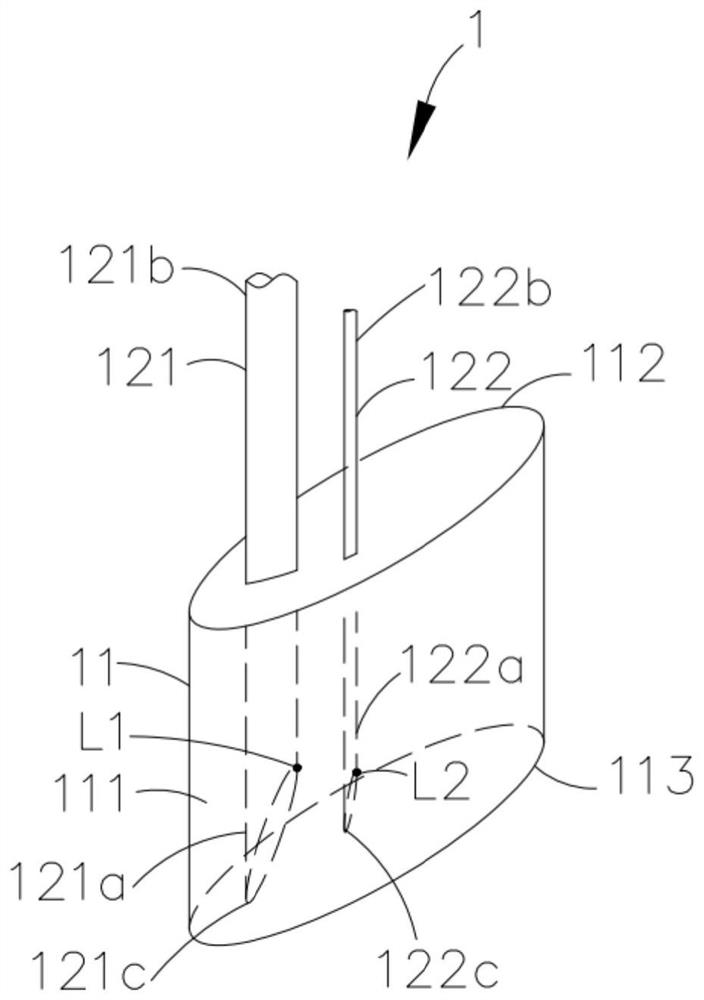

[0044] Please also refer to Figure 1 to Figure 2 , an oil return structure 1 provided by the present invention, the oil return structure 1 includes a first device 11 and at least one standpipe 12, the nozzle 12c of the first end 12a of the standpipe 12 is an oblique opening, and the standpipe The first end 12a of 12 extends into the accommodating chamber 111 and is fixed in the accommodating chamber 111, and the oblique opening is completely located in the accommodating chamber 111, and the standpipe 12 is used to transport the fluid in the accommodating chamber 111 .

[0045] Wherein, the nozzle 12c of the first end 12a of the standpipe 12 is oblique, that is, the length direction of the standpipe 12 is not perpendicular to the cross section of the nozzle 12c of the standpipe 12 . The bevel can be formed by cutting the first end 12a of the riser 12 at a certain oblique angle. The effect of setting the bevel is that since the bevel is not flat, when the standpipe 12 is arra...

Embodiment 2

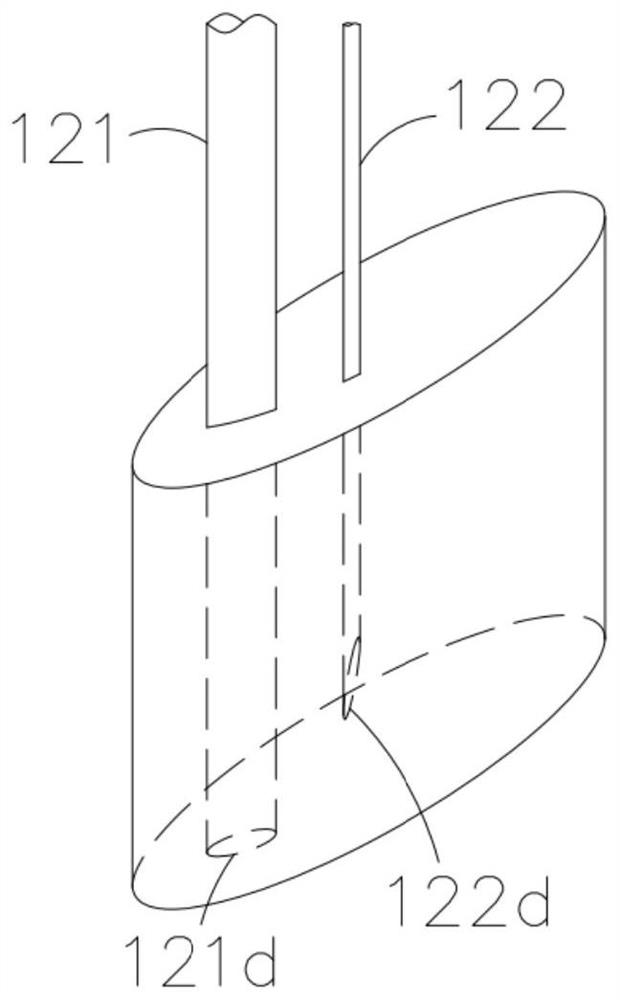

[0058] Embodiment 2 of the present invention provides an oil return structure. The difference between this oil return structure and the oil return structure in Embodiment 1 is that when there are multiple standpipes, take the case of two standpipes as an example (such as image 3 shown), the two standpipes can be respectively the first riser 121 and the second riser 122, the first standpipe 121 and the second standpipe 122 are arranged at intervals, and the nozzle 121d of the first riser 121 is a flat mouth, The nozzle 122d of the second riser 122 is an oblique opening.

[0059] The oil return structure provided by Embodiment 2 of the present invention adopts the method that some risers are arranged with flat openings, and some of the risers are arranged with inclined openings, which can reduce the production of inclined opening risers, and the risers with flat openings can be recycled for other In the application occasion, the utilization rate of the equipment is improved.

Embodiment 3

[0061] see Figure 4 , which is a structural schematic diagram of an oil return device for an ascending return steam riser provided by the present invention. The rising steam riser oil return device can be applied to a refrigeration system, the refrigeration system includes an evaporator 5 and a compressor 6, and the rising steam riser oil return device includes a first pipeline 2, a second pipeline 3 and an oil return structure 1.

[0062] Wherein, the oil return structure 1 is the oil return structure 1 as described in the first embodiment. For the specific structural design of the oil return structure 1, please refer to the first embodiment, which will not be repeated here.

[0063] Wherein, one end of the first pipeline 2 is connected to the evaporator 5, the other end of the first pipeline 2 communicates with the accommodating cavity 111 of the first device 11 of the oil return structure 1, and one end of the second pipeline 3 is connected to the return The second end 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com